Fixing structure for plastocene model ABS component

A technology for fixing structure and sludge model, applied in teaching models, educational appliances, instruments, etc., can solve problems such as affecting installation accuracy, falling off of ABS parts, and damage to circular holes in sludge, saving material costs, preventing falling off, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

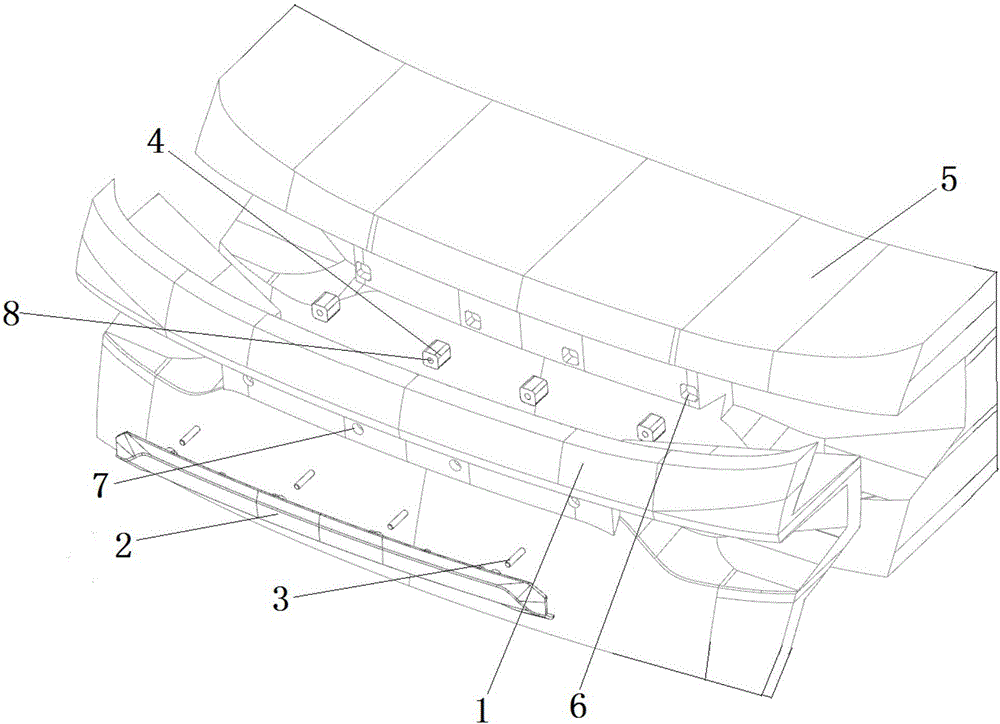

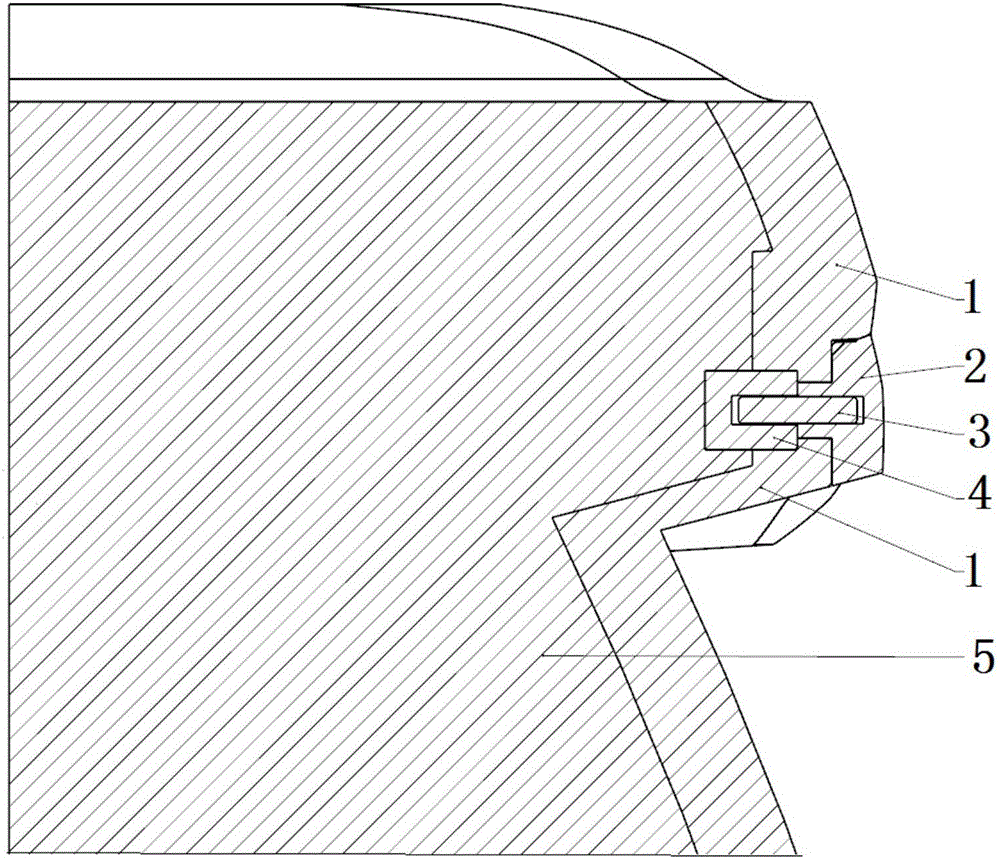

[0028] Such as Figure 1-2 Shown, a kind of fixing structure for the ABS part of the sludge model, the fixing structure includes the core foam member 5, the sludge covering layer member 1 arranged on the core foam member 5 and the ABS member fixedly connected with the sludge covering layer member 1 2. The fixed structure also includes a positioning installation unit, which includes a positioning piece 3 arranged on the back of the ABS component 2 and a limit block 4 used in conjunction with the positioning piece 3. The oil sludge covering layer component 1 is provided with a positioning piece 3 passes through the limiting hole 7, the limiting block 4 is set on the core foam member 5, the positioning piece 3 passes through the limiting hole 7 on the oil sludge cover member 1, and is connected with the limiting hole 7 on the core foam member 5 The blocks 4 are connected to jointly fix the ABS component 2 on the oil mud covering layer component 1.

[0029] There are four positio...

Embodiment 2

[0033] In this embodiment, there are 3 positioning pieces 3 and 3 limiting blocks 4 , which are respectively arranged in one-to-one correspondence with the positioning pieces 3 . All the other are with embodiment 1.

Embodiment 3

[0035] In this embodiment, there are 6 positioning pieces 3 in total, and 6 limiting blocks 4 are also provided, and they are respectively arranged in one-to-one correspondence with the positioning pieces 3 . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com