A Pilot Safety Valve System

A pilot-operated safety valve, pilot valve technology, applied in the direction of safety valve, lift valve, balance valve, etc., can solve the problems of safety valve without position indicator, no auxiliary isolation function, accurate action and low life, to reduce the first time. Leakage time, quick action, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

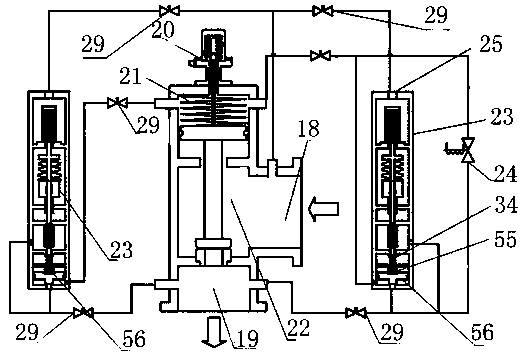

[0034] Such as figure 1 As shown, a pilot safety valve system of the present invention includes a main valve 22, a pilot valve 23 and a release valve 24. The main valve 22 is provided with a main valve inlet 18, a main valve outlet 19 and a flow channel hole 17. The pilot valve 23 It is provided with an upper end pressure sensing chamber inlet 25, a discharge hole 26, a relay valve inlet 27 and a relay valve outlet 28, and the main valve inlet 18 communicates with the upper end pressure sensing chamber inlet 25 of the pilot valve 23 through a pipeline and an isolation valve 29, and the flow The channel hole 17 communicates with the relay valve inlet 27 of the pilot valve 23 through the pipeline and the isolation valve 29, and the main valve outlet 19 of the main valve 22 is respectively connected with the discharge hole 26 of the pilot valve 23 and the relay valve outlet 28 through the pipeline and the isolation valve 29. connected.

[0035] When the system pressure is normal...

Embodiment 2

[0037] Such as figure 1 As shown, a pilot-operated safety valve system of the present invention, on the basis of Embodiment 1, the inlet of the release valve 24 communicates with the flow channel hole 17 through the pipeline and the isolation valve 29, and the outlet of the release valve 24 communicates with the main valve through the pipeline and the isolation valve 29. The valve outlet 19 is connected, and the release valve 24 realizes the forced release function by remotely manually controlling the opening and closing of the main valve 22 .

[0038] When the system requires manual remote forced pressure relief, the power supply of the release valve 24 is turned on, and the disc of the release valve 24 is pulled apart under the action of electromagnetic force, and the pressure medium in the piston chamber 21 of the main valve is released through the release valve 24 to make the main valve The pressure in the piston chamber 21 decreases, and the piston 7 of the main valve 22 ...

Embodiment 3

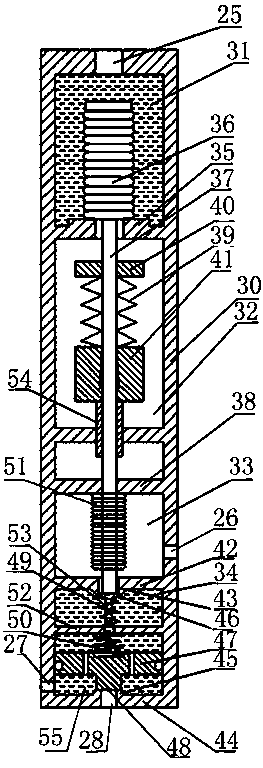

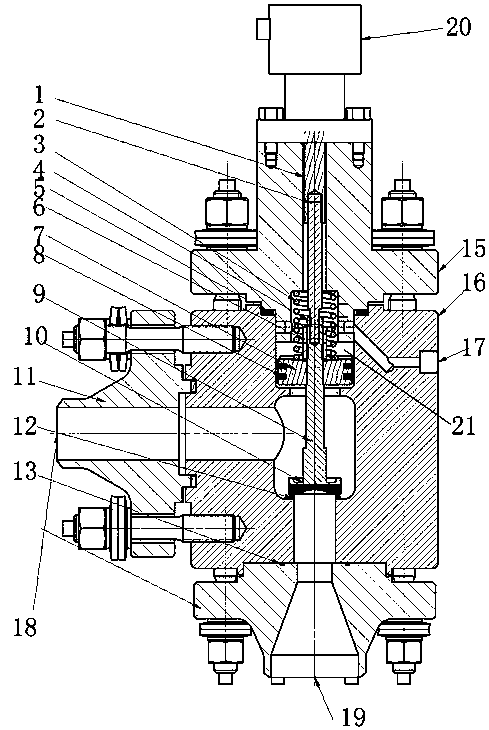

[0040] Such as figure 2 As shown, the structural diagram of the main valve of the present invention, on the basis of Embodiment 1, the main valve 22 includes an upper head 15 and a valve body 16, and the top of the upper head 15 is provided with a position indicator 20; the bottom of the upper end 15 Set on the upper end of the valve body 16, the inside of the upper head 15 is provided with a position sensing block 1 and a connecting rod 2 sequentially from top to bottom, and the sensing block 1 is connected to the connecting rod 2; the inside of the valve body 16 is arranged sequentially from top to bottom There are return spring 3, valve stem 9, piston assembly, valve disc 10 and valve seat 12, the valve stem 9 is connected with the connecting rod 2, the piston assembly is arranged on the valve stem 9, the bottom of the valve stem 9 is provided with a valve disc, the valve The valve seat 12 is closely attached to the valve seat 12. The valve seat 12 can be directly welded t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com