Comprehensive smoke purification technical method

A flue gas and incineration flue gas technology, applied in the field of environmental energy, can solve the problems of poor removal of harmful substances and unreasonable flue gas treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

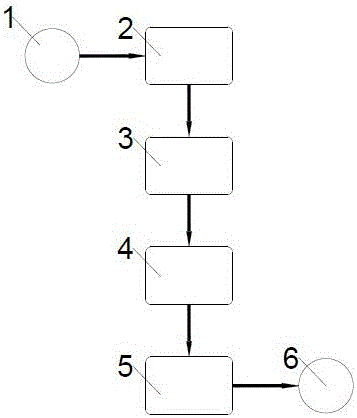

[0014] After municipal solid waste enters the pyrolysis combustion device, the flue gas 1 produced after a series of processes such as drying, pyrolysis, and oxidative decomposition enters the pyrolysis chamber through the return pipe for high-temperature flue gas utilization 2 as a heat source for waste pyrolysis Supplement, reduce energy consumption in the pyrolysis process; then discharge into the garbage drying room for flue gas cooling and reuse 3, make full use of the heat energy in the flue gas to dry the garbage, reduce the moisture content, and at the same time achieve the effect of flue gas cooling Purpose: The flue gas after cooling is discharged from the garbage pyrolysis combustion device, and enters the alkali washing tank for alkali washing of the flue gas 4 to remove acid gas and dust in the flue gas; the flue gas after alkali washing is dehydrated for flue gas drying 5 , to remove the water vapor mixed in the flue gas; after the dried flue gas is tested to meet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com