Uncooled infrared detector and manufacture method therefor

An uncooled infrared and detector technology, applied in the direction of electric radiation detectors, etc., can solve the problems of insufficient infrared absorption ability of infrared detectors, use restrictions, affecting the detection ability and application range of infrared detectors, etc., and achieves the improvement of infrared heat Radiation absorption ability, the effect of improving the infrared absorptivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

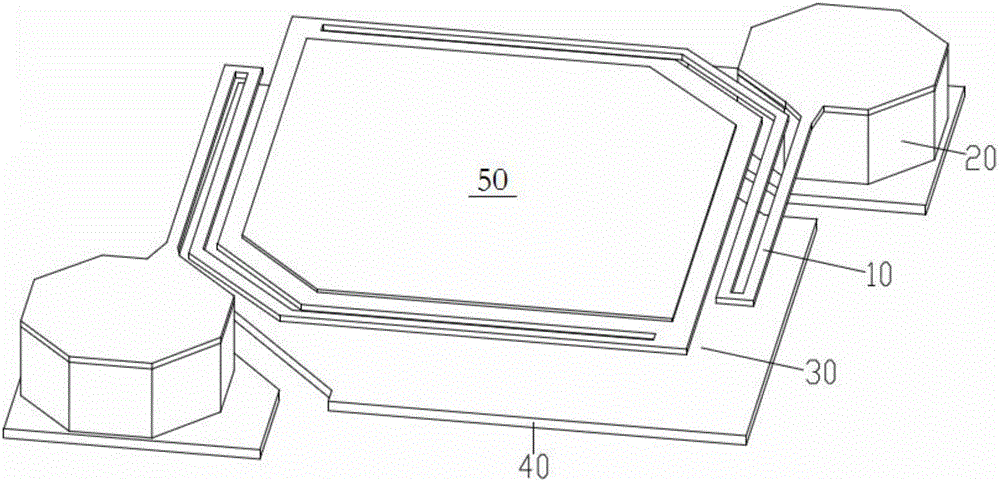

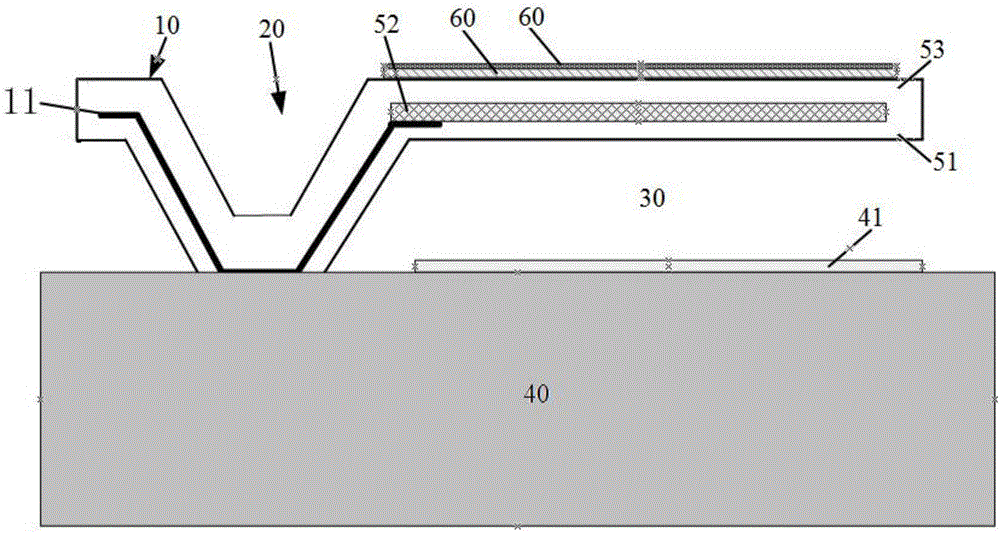

[0029] like figure 1 and figure 2 , the embodiment of the present invention relates to an uncooled infrared detector, in particular to an uncooled infrared focal plane array detector, comprising a bridge deck 50, a bridge leg 10, an anchor column 20 and a substrate 40, the uncooled infrared detector in the prior art Cooled infrared detectors are suitable for this embodiment. The detector further includes at least one layer of auxiliary infrared absorbing layers 60 , and each auxiliary infrared absorbing layer 60 is stacked on the upper surface of the bridge deck 50 . By additionally adding an auxiliary infrared absorbing layer 60 on the top of the bridge deck 50, which cooperates with the infrared absorbing layer of the bridge deck 50, can effectively improve the infrared heat radiation absorption capacity of the detector, thereby improving the temperature response rate of the detector and reducing NETD.

[0030] Wherein, the structure of each layer of auxiliary infrared ab...

Embodiment 2

[0047] This embodiment provides an uncooled infrared detector, in which a metal conductive layer, an infrared radiation reflection layer, a sacrificial layer, a sensitive material support layer, a bridge deck infrared absorption layer, a sensitive material layer, a metal electrode layer and at least one auxiliary infrared absorbing layer, forming figure 1 Infrared detector shown. The structure of the above-mentioned auxiliary infrared absorbing layer 60 is the same as that of the auxiliary infrared absorbing layer 60 in the first embodiment above, and will not be repeated here.

[0048] The embodiment of the present invention relates to the preparation method of the above-mentioned uncooled infrared detector, comprising the following steps:

[0049] S1: Deposit and pattern a metal conductive layer and an infrared radiation reflective layer on the readout circuit;

[0050] S2: Depositing a sacrificial layer, and patterning to form support holes and electrical via holes;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com