Infrared camera mechanical structure

An infrared camera and mechanical structure technology, applied in the infrared field, can solve the problems of high cost and high processing precision requirements, and achieve the effects of simple focusing method, reduced manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

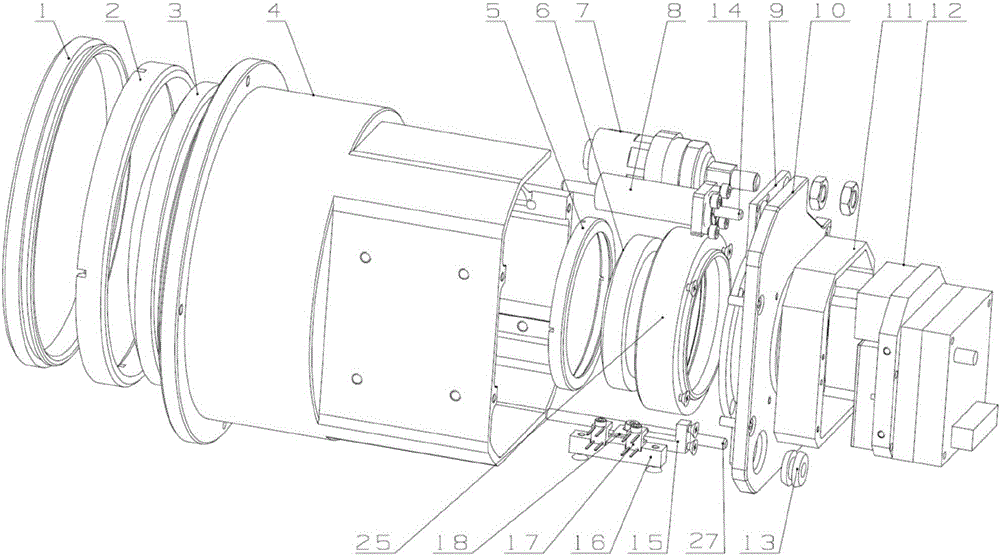

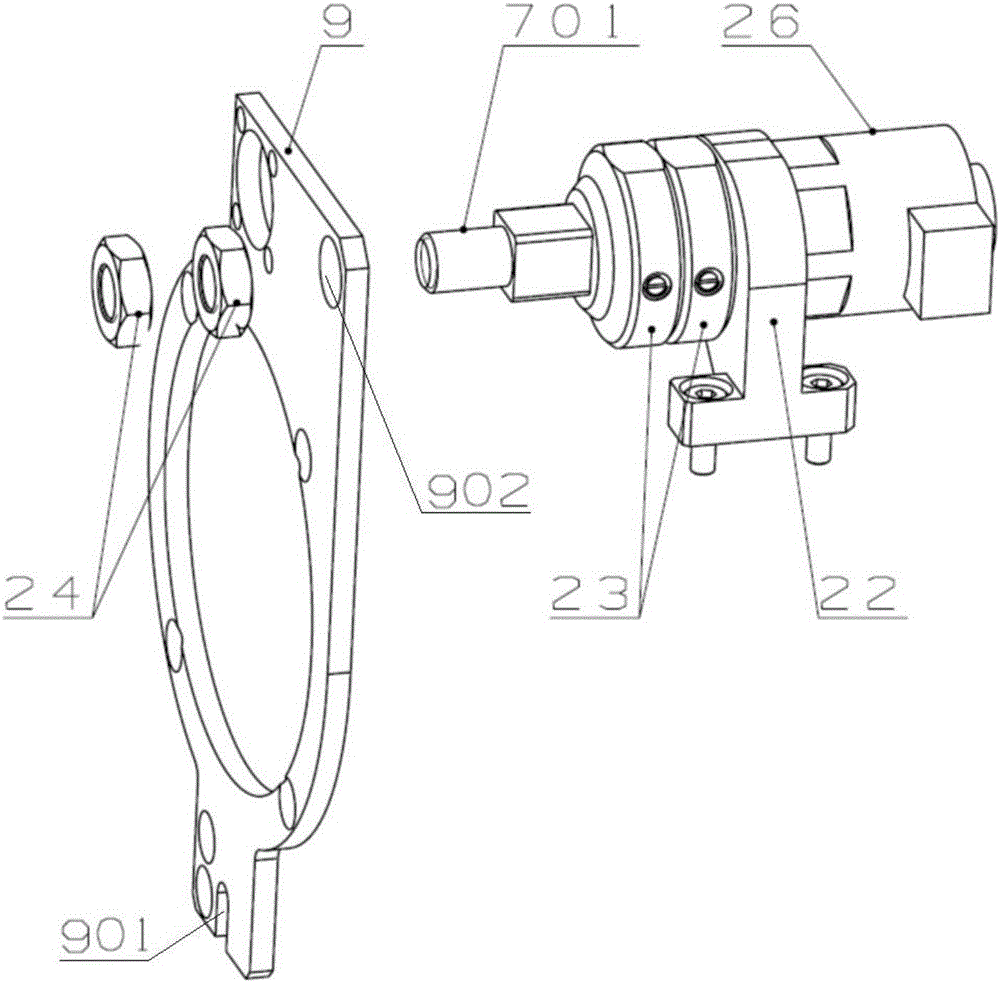

[0040] Such as Figure 1 to Figure 6 As shown, a mechanical structure of an infrared camera of the present invention mainly includes: a mirror cover 1, a pressure ring 1 2, a lens 3, a lens barrel 4, a pressure ring 2 5, a lens 2 6, a linear motor assembly 7, and a guide assembly 8 , Stress plate 9, rear cover 10, detector seat 11, detector 12, grommet 13, block mounting seat 15, photoelectric switch seat 16, two photoelectric switches 17, block plate 18, focusing lens seat 25 .

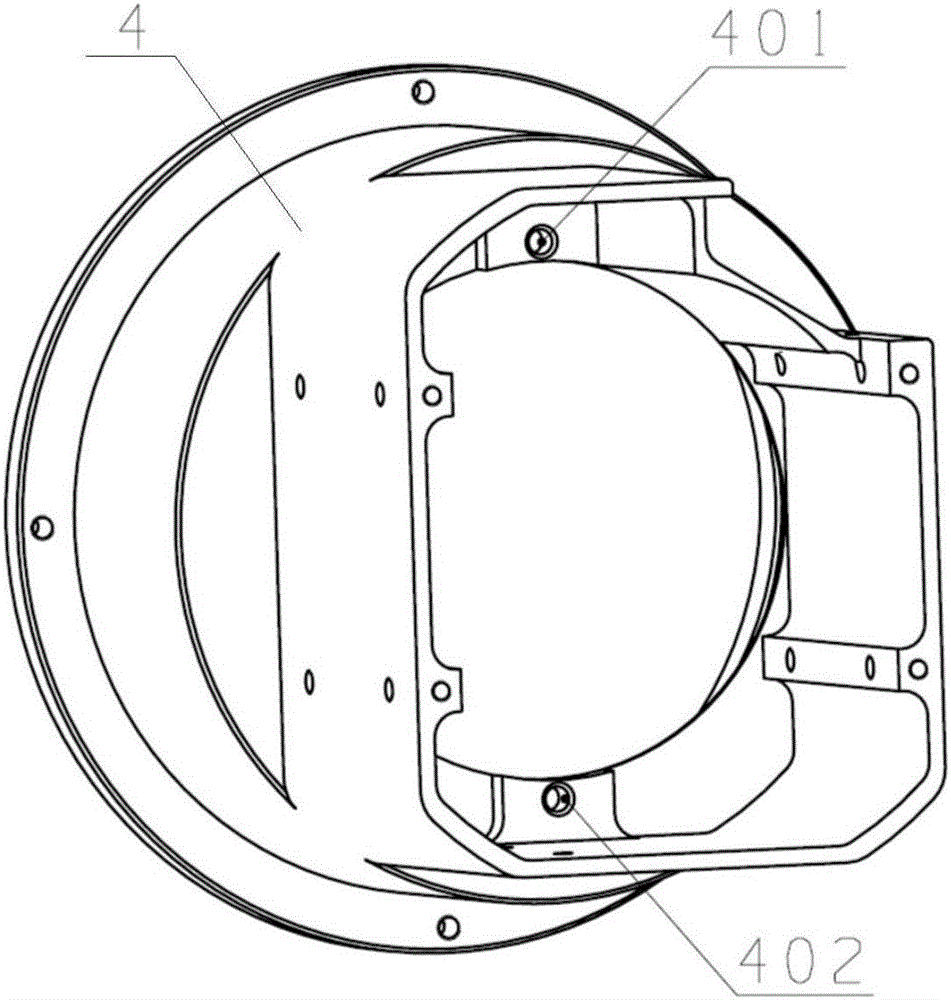

[0041] Such as figure 2 As shown, the front end of the lens barrel 4 is provided with a flange, and the rear end of the lens barrel 4 is provided with a mounting structure. The inner and lower sides of the structure are provided with three cylinder positioning holes 401 and four cylinder positioning holes 402 .

[0042] Lens one 3 is fixed on the lens barrel 4 by pressure ring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap