Design method for improving anti-collapse ability of RC frame core tube structure

A design method and core technology, applied in design optimization/simulation, calculation, geometric CAD, etc., can solve the problem of lack of in-depth understanding and understanding of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Take the failure of a certain component as an example to describe the specific implementation of the present invention in detail. The steps of the design method for improving the anti-collapse ability of the RC frame core tube structure of the present invention are as follows:

[0033] Step (1): According to the established conditions, the RC frame core tube structure is conventionally designed to obtain the initial structural model.

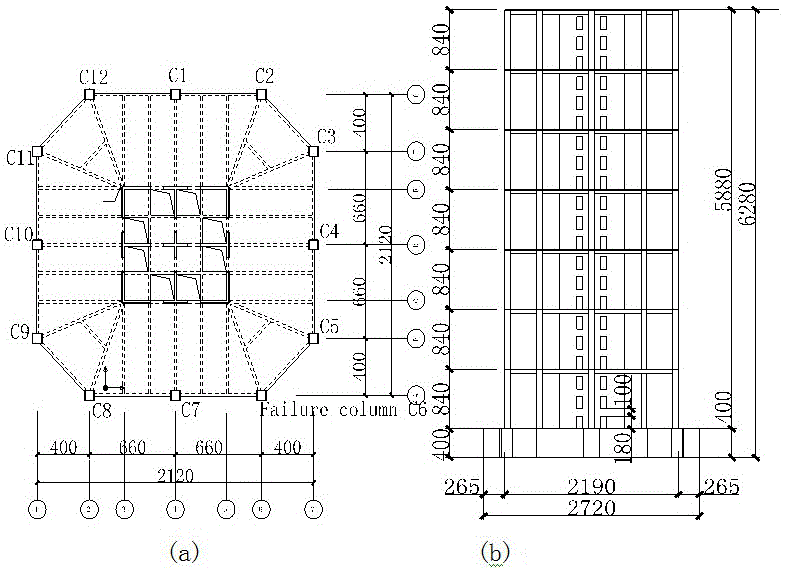

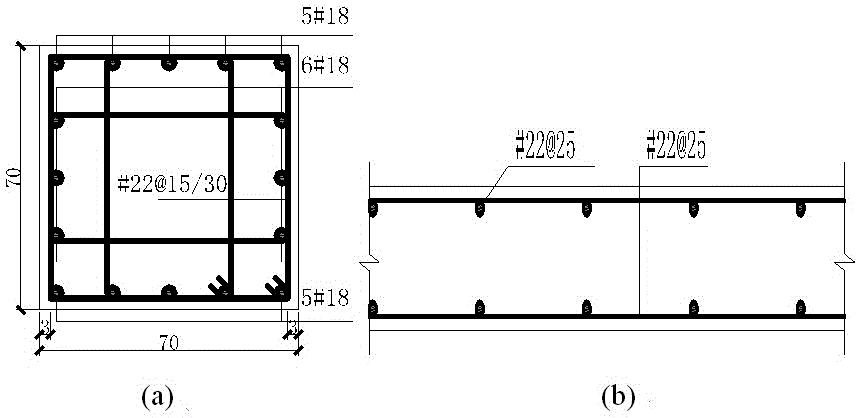

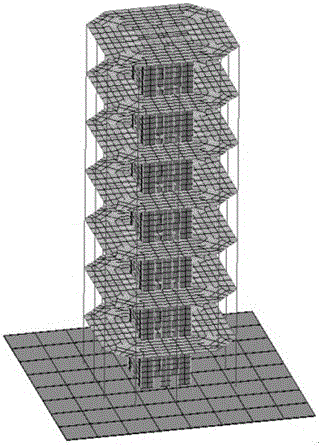

[0034] The plan and elevation layout of the structure is as follows: figure 2 and image 3 As shown, consider the seismic fortification of degree 7 in the Shanghai area, the site soil of category IV, the first group of fortification anti-seismic grouping, and the effect of wind load is not considered. According to the "Code for Design of Concrete Structures" GB 50010-2010, PKPM software is used for structural design and reinforcement calculation. The layout of beam members is as follows Figure 4 As shown, Table 1 lists...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com