Crystalline silicon cell and its preparation method

A technology of crystalline silicon cells and crystalline silicon wafers, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of poor resistance to high and low temperature cycle changes of welding electrodes, affecting the overall performance of packaging components, and poor consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

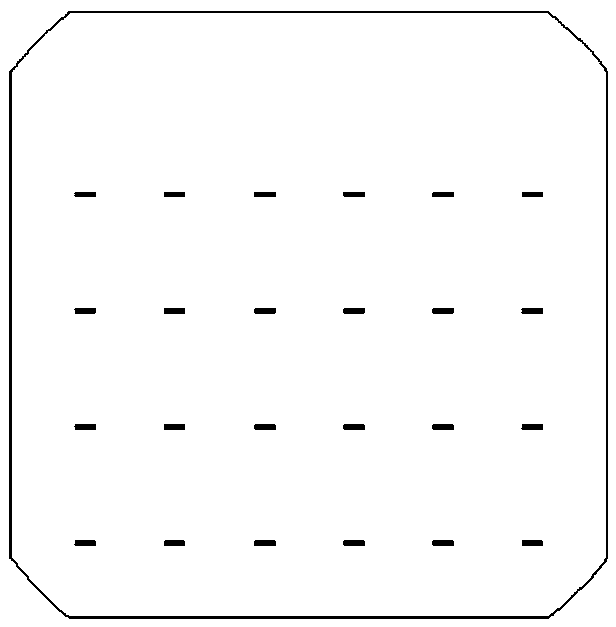

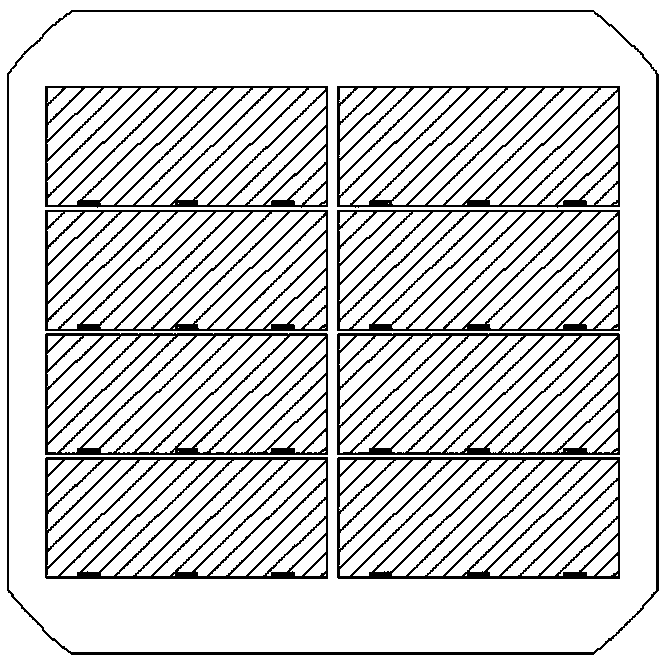

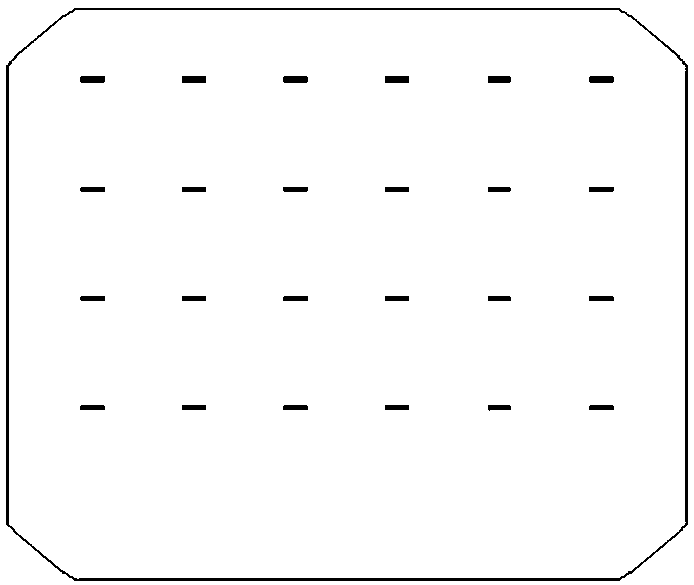

[0037] A crystalline silicon cell of the present invention comprises a crystalline silicon cell substrate, a finger grid electrode, a welding electrode, a back electrode and an aluminum back conductive layer, the finger grid electrode and the welding electrode are arranged on the front of the crystal silicon cell substrate, and the back electrode And the aluminum back conductive layer is arranged on the back of the crystalline silicon cell substrate; wherein, the square resistance value of the area corresponding to the welding electrode on the front of the crystalline silicon cell substrate is 40Ω / □~50Ω / □, and the thickness of the aluminum back conductive layer is thicker than the back electrode 1 μm higher, the thickness of the finger grid electrode is 1 μm higher than that of the welding electrode.

[0038] In this embodiment, the crystalline silicon cell substrate includes SiNx anti-reflection film, SiO 2 Thin films, PN junctions, front textured crystalline silicon wafers, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com