Novel CVT dry-type electromagnetic unit

An electromagnetic unit, dry technology, applied in the field of CVT, can solve the problems of inconvenient installation and transportation, large eddy current impedance noise, complex manufacturing process, etc., and achieve the effect of reducing partial discharge level, short magnetic circuit length and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

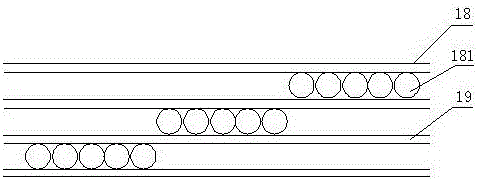

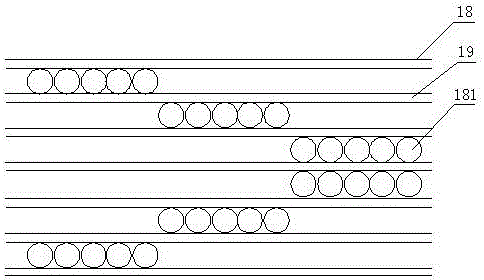

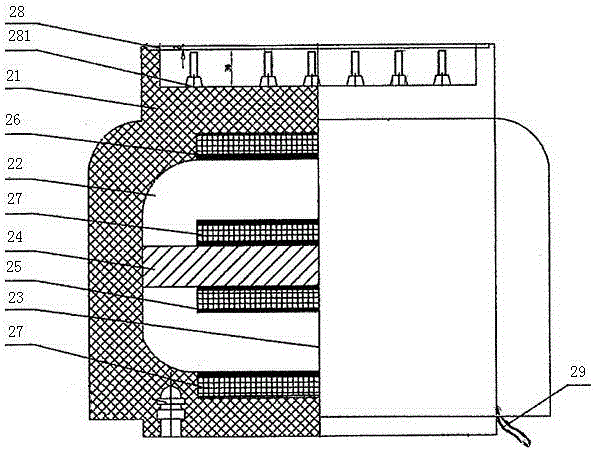

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Such as figure 1 As shown: the new CVT dry-type electromagnetic unit of this embodiment includes an intermediate transformer 1, a compensating reactor 2 and a speed saturation damper 3; The voltage terminal, the secondary outlet terminal 12 of the intermediate transformer 1 is connected to the low voltage terminal of the capacitive voltage divider 4 through the first concave adjustment box 13; the intermediate transformer 1, compensating reactor 2 and speed saturation damper 3 are all cast and packaged by insulating resin Molded and installed in the box body 5.

[0031] In this embodiment, the intermediate transformer 1, the compensating reactor 2 and the fast saturation damper 3 are molded by casting and encapsulating the insulating resin. On the one hand, the structure of each device is relatively compact, and the overall st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com