Actuating structure of electrical connector

A technology for actuating structures and electrical connectors, which is applied to conductive connections, connections, and components of connecting devices, etc., can solve the problem of reducing the size and height of connectors, increasing the overall height and complexity of structural design, and difficulty in joining and fixing. and other problems, to achieve the effect of firm clamping, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to achieve the above-mentioned purpose and effect, the technical means adopted in the present invention, its structure, and the method of implementation, etc., are hereby described in detail with respect to the preferred embodiments of the present invention. Its features and functions are as follows, so that it can be fully understood.

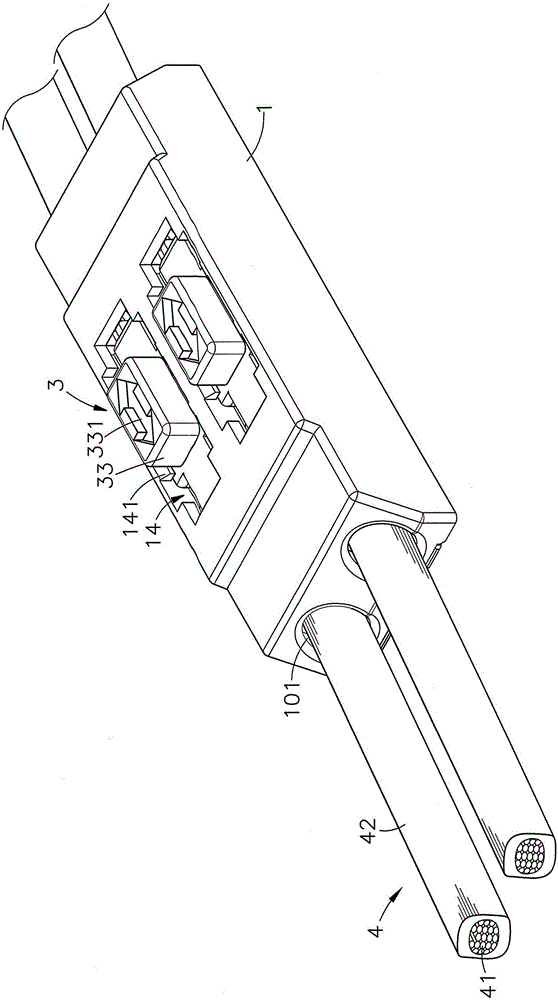

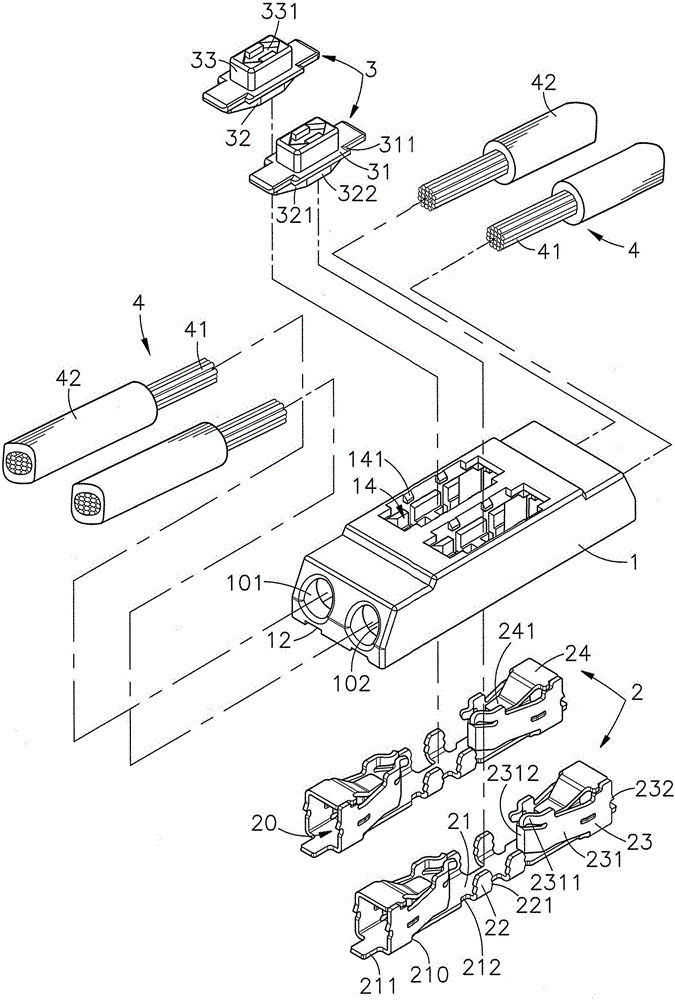

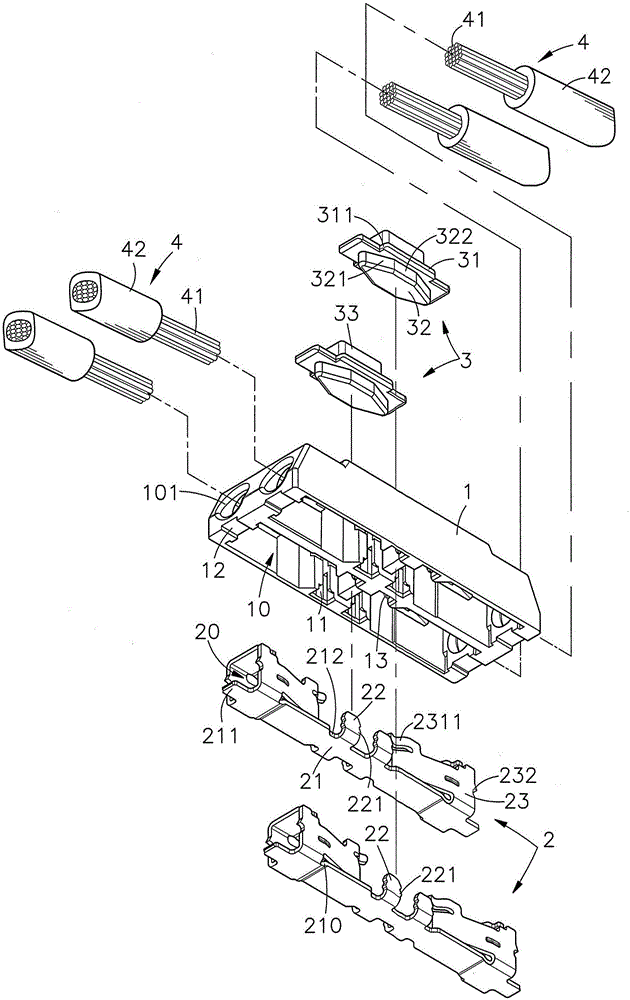

[0034] see figure 1 , figure 2 , image 3 , Figure 4 As shown, it is a three-dimensional appearance view, a three-dimensional exploded view, a three-dimensional exploded view of another angle, and a side sectional view of a preferred embodiment of the present invention. It can be clearly seen from the figure that the present invention includes a seat body 1, Clamping terminal 2 and pushing block 3, wherein:

[0035] The hollow of the base body 1 is respectively provided with two sets of two accommodating spaces 10 with openings 101 at the front and rear, and the central upper surface of the base body 1 is provided with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com