Method for correcting unbalance of rotor

A rotor and balancing technology, applied in the direction of adjusting/balancing rotors, electromechanical devices, electrical components, etc., can solve problems such as unbalance correction, cumbersome, complicated rotor structure, etc., and achieve the effect of complexity suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, one embodiment of the present invention will be described based on the drawings.

[0030] [Structure of polygon mirror scanner motor]

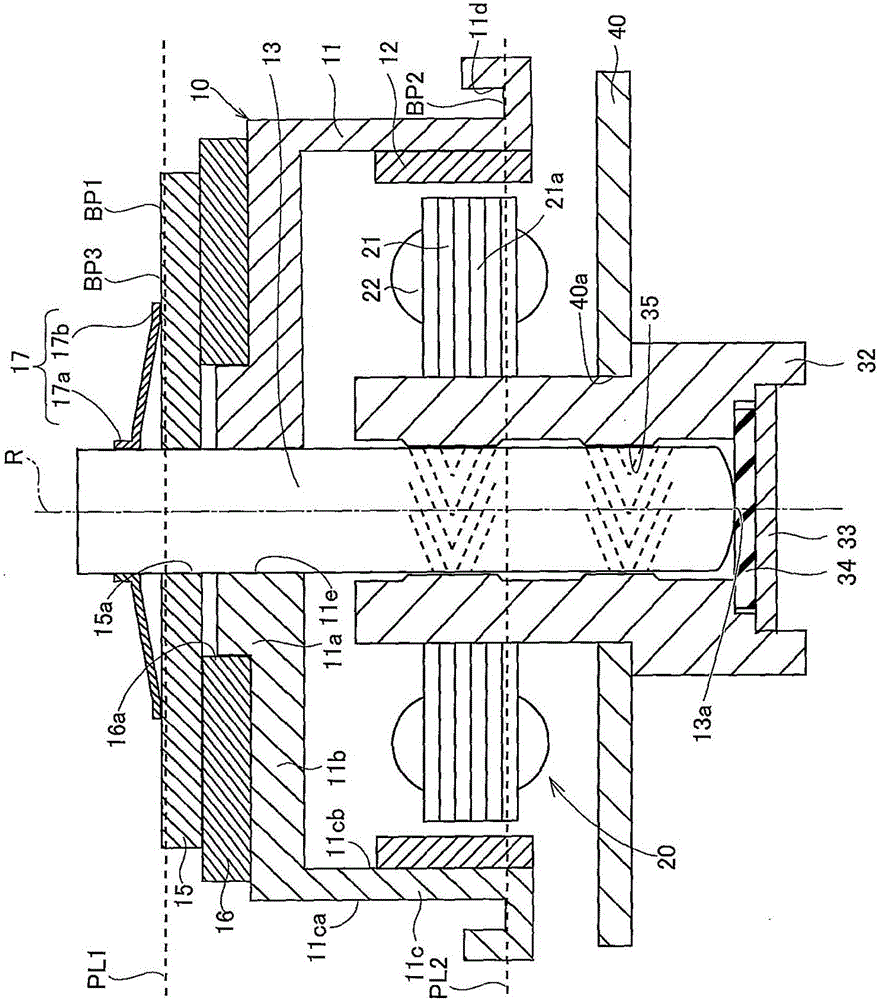

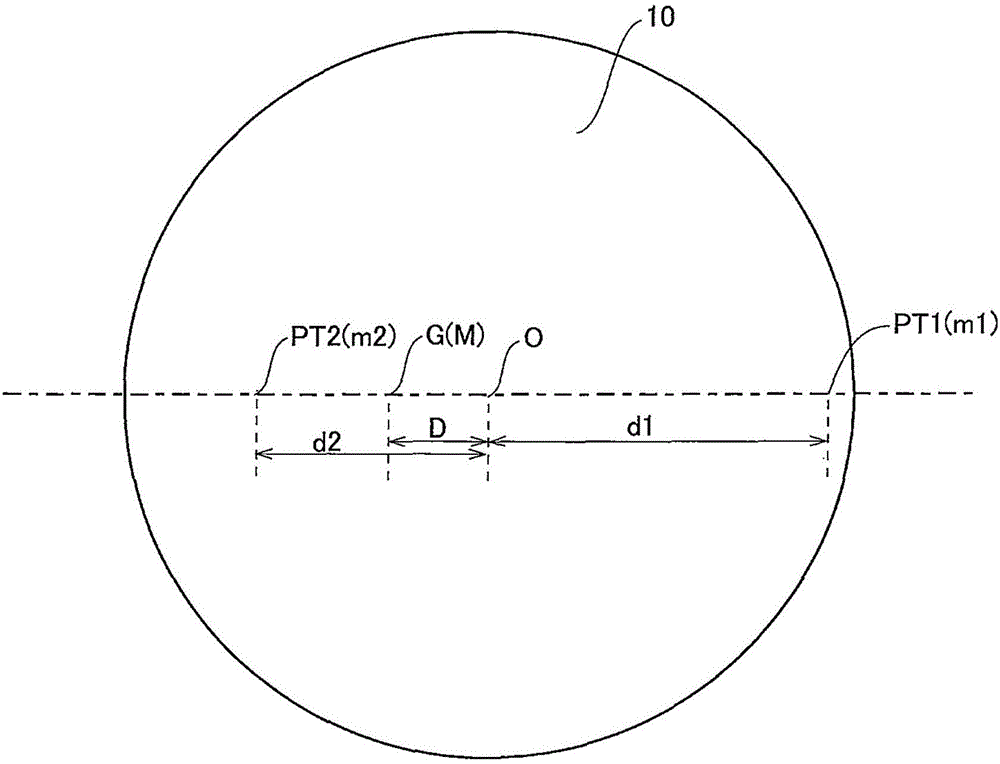

[0031] figure 1 It is a cross-sectional view schematically showing the structure of the polygon mirror scanner motor before the unbalance of the rotor is corrected in one embodiment of the present invention.

[0032] figure 1 The shown polygon mirror scanner motor in this embodiment drives the polygon mirror to rotate. The polygon mirror scanner motor mainly includes a rotor 10 and a stator 20 . The rotor 10 is supported by a stator case 32 . The rotor 10 rotates about the rotation axis R relative to the stator 20 .

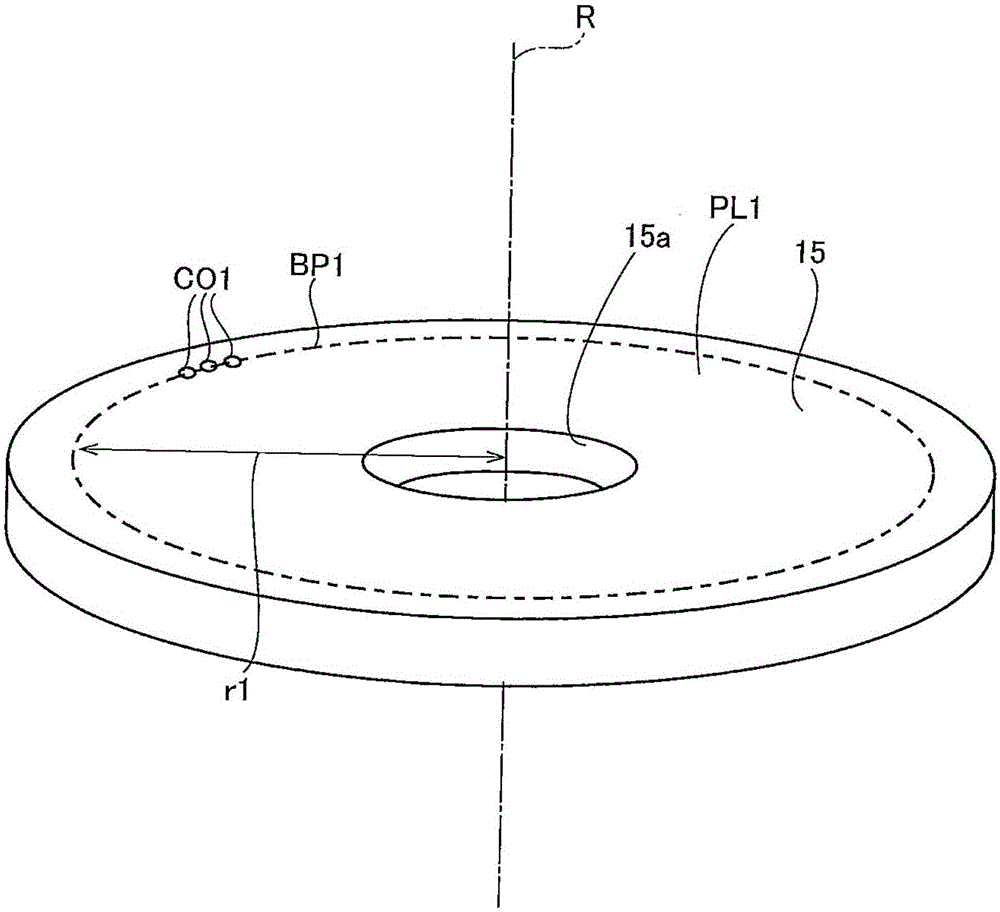

[0033] The rotor 10 includes a rotor frame 11 , a magnet 12 , a shaft 13 , a top plate 15 , a polygon mirror 16 , and a compression spring 17 . The shaft 13 has a cylindrical shape, and a dynamic pressure groove is formed on either surface of the shaft 13 or the inner diameter portion of the stator case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com