Grooved wheel type fluid dibble-seeding machine

A kind of hole seeding machine and fluid technology, which is applied in the field of groove wheel type fluid hole seeding machine, can solve the problems such as the failure to achieve the seeding accuracy and the hole forming effect, and achieve the effects of simple structure, uniform seeding and reliable implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

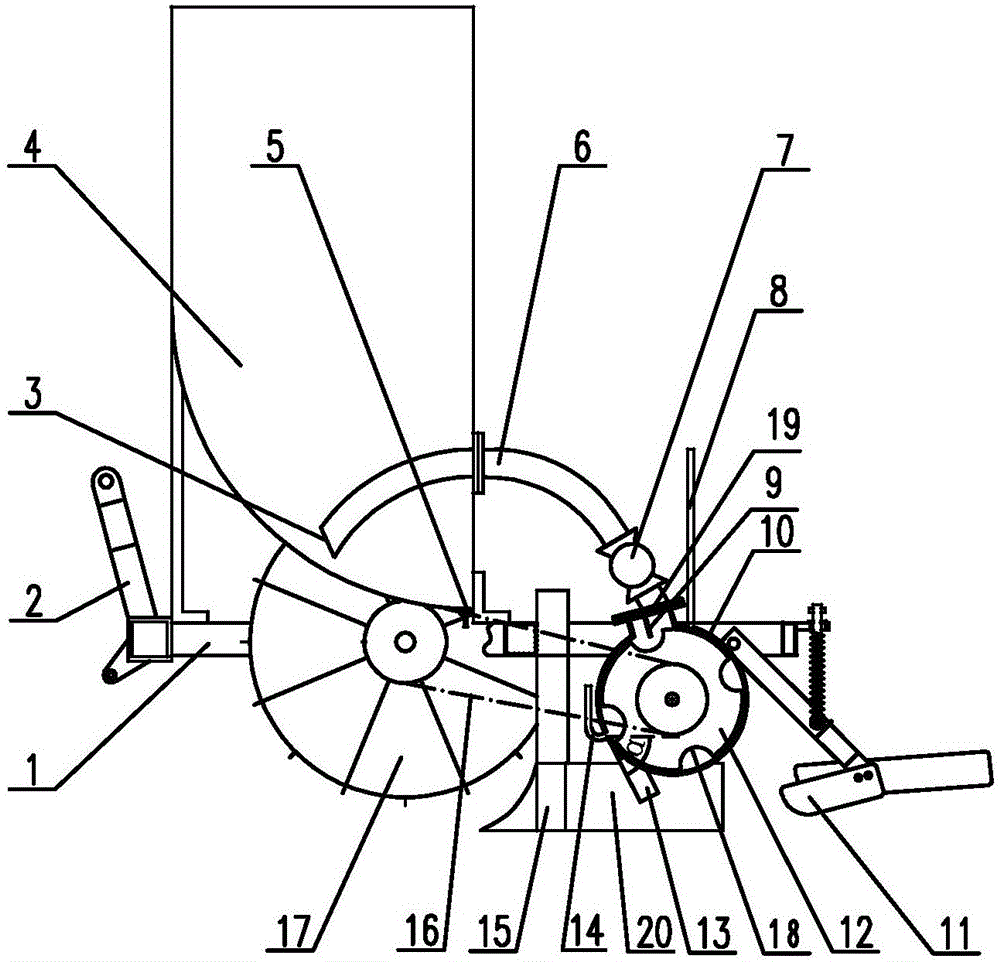

[0028] Embodiment 1: as figure 1 As shown, the present invention includes:

[0029] The frame 1 is connected with the suspension device 2 for suspension power, and is connected with the tractor through the suspension device 2;

[0030] The seed solution box 4 is placed on the frame 1, with built-in seeds and seed solution. The bottom of the seed solution box 4 is provided with an aeration device 5, and the aeration device 5 is used to ventilate, stir and mix, so that the seeds are evenly distributed in the seed solution box 4;

[0031] The drainer is connected to the seed liquid tank 4 through the siphon 6;

[0032] Ditch opener 15, connected on the frame 1, is located at the front end of the drainer, and is used for ditching when sowing;

[0033] Soil-covering device 11, connected to the frame 1, located at the rear end of the drainer, covers the soil after sowing;

[0034] Ground wheels 17 are placed on both sides of the frame 1, supporting the frame 1 and driving the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com