micro harvester

A harvester and miniature technology, which is applied to harvesters, agricultural machinery and tools, agriculture, etc., can solve the problems that large-scale machinery cannot be used for crop planting, and achieve the effects of saving costs, improving work efficiency, and ensuring the effect of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

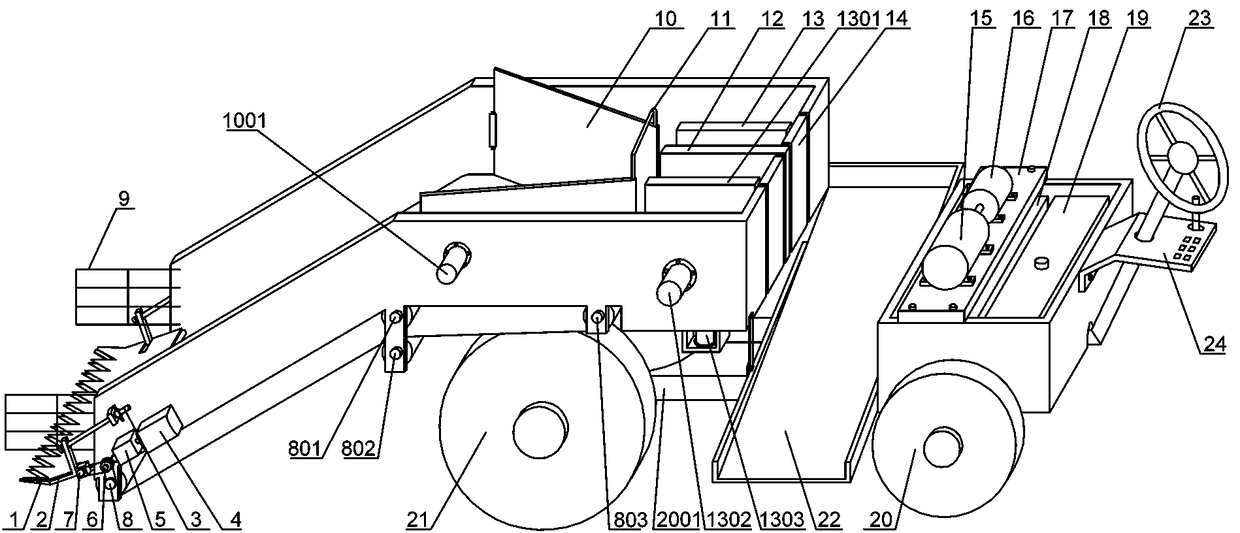

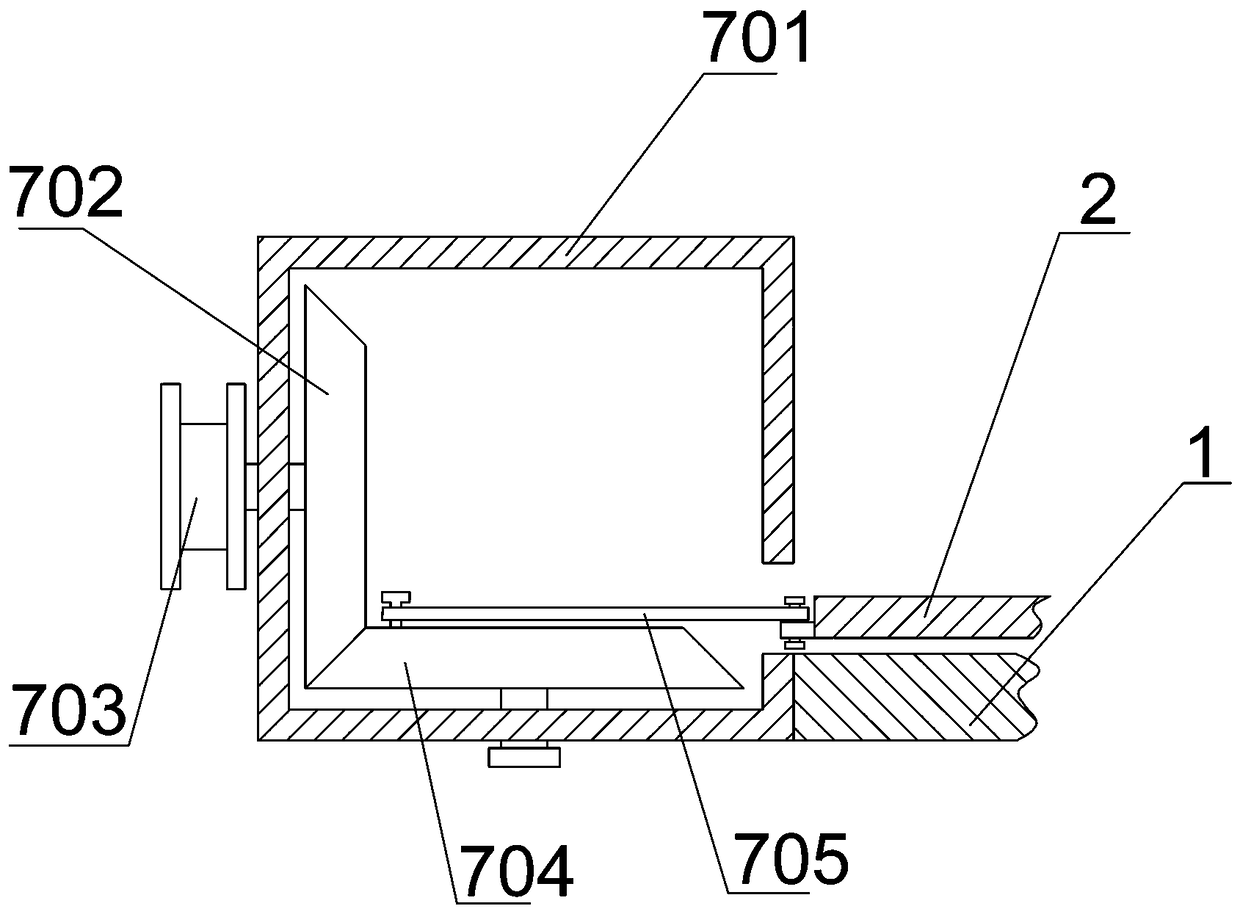

[0025] Such as Figure 1-2 , miniature harvester, it comprises drive wheel 20, and described drive wheel 20 links to each other with front wheel 21 by connecting shaft 2001, and described drive wheel 20 and front wheel 21 are all installed in the bottom of frame, and the head of described frame Harvesting cutter device is installed, and described harvesting cutter device links to each other with cutting device 7, and conveyer belt device 8 is connected behind described harvesting cutter device, and the top end of described driving belt device 8 is equipped with shift plate 10, and described shifter A side platen device 13 is arranged behind the position plate 10, and the end of the side platen device 13 is connected with a downhill groove 22, and a main motor 15 and a hydraulic pump 16 are installed at the tail of the frame, and the main motor 15 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com