Frozen oolong

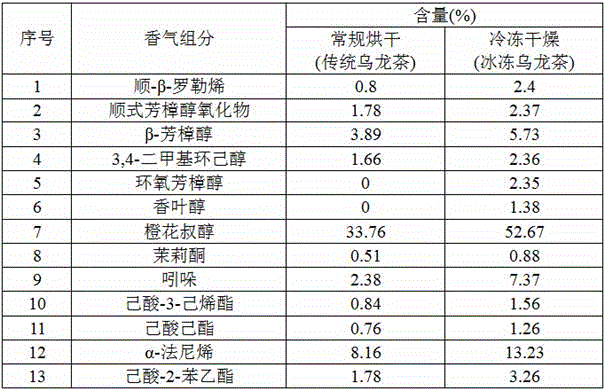

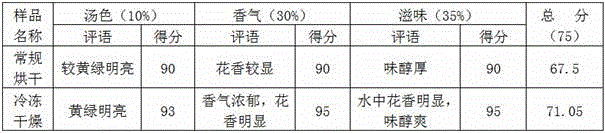

A technology of oolong tea and drying green, which is applied in tea treatment before extraction, etc. It can solve the problems of brewing with stalks, adding oolong tea, and difficult preservation, and achieves the effect of mellow taste, increased aroma, and rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of frozen oolong tea, its preparation method comprises the following steps:

[0034] 1) Raw material picking: choose fresh leaves of 'Golden Guanyin' planted at an altitude of 600-800m and open in the middle (standing buds are formed at the top, and the area of the top leaf is 1 / 3-1 / 2 of the second leaf) as raw materials. Picking from 11:00 noon to 3:00 pm on sunny days;

[0035] 2) Green drying: at 4-5 pm on a sunny day, evenly spread the picked fresh leaves on the drying cloth with a thickness of 5cm, and dry them for 20 minutes, so that the water loss rate of the fresh leaves is 8%;

[0036] 3) One-time drying: turn the sun-dried green leaves and put them in a withering room or an air-conditioned room at 23°C for the first drying (no need to put on a sieve rack), and the drying time is 1 hour;

[0037] 4) One-time green shaking: Add air-dried green leaves according to 60% of the volume of the green shaking bucket for the first shaking. The rotation speed of...

Embodiment 2

[0051] A kind of frozen oolong tea, its preparation method comprises the following steps:

[0052] 1) Raw material picking: choose fresh leaves of 'Golden Guanyin' planted at an altitude of 600-800m and open in the middle (standing buds are formed at the top, and the area of the top leaf is 1 / 3-1 / 2 of the second leaf) as raw materials. Picking from 11:00 noon to 3:00 pm on sunny days;

[0053]2) Green drying: at 4-5 pm on a sunny day, evenly spread the picked fresh leaves on the green drying cloth with a thickness of 8cm, and dry them in the sun for 20 minutes, so that the water loss rate of the fresh leaves is 6%;

[0054] 3) One-time drying: turn the sun-dried green leaves and put them in a withering room or an air-conditioned room at 25°C for the first drying (without a sieve rack), and the drying time is 1 hour;

[0055] 4) One-time green shaking: Add air-dried green leaves according to 60% of the volume of the green shaking bucket for the first shaking. The rotation sp...

Embodiment 3

[0069] A kind of frozen oolong tea, its preparation method comprises the following steps:

[0070] 1) Raw material picking: choose fresh leaves of 'Golden Guanyin' planted at an altitude of 600-800m and open in the middle (standing buds are formed at the top, and the area of the top leaf is 1 / 3-1 / 2 of the second leaf) as raw materials. Picking from 11:00 noon to 3:00 pm on sunny days;

[0071] 2) Green drying: at 4-5 pm on a sunny day, evenly spread the picked fresh leaves on the drying cloth with a thickness of 6cm, and dry them for 20 minutes, so that the water loss rate of the fresh leaves is 7%;

[0072] 3) One-time drying: turn the sun-dried green leaves and put them in a withering room or an air-conditioned room at 24°C for the first drying (no need to put on a sieve rack), and the drying time is 1 hour;

[0073] 4) One-time green shaking: Add air-dried green leaves according to 60% of the volume of the green shaking bucket for the first shaking. The rotation speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com