Roughing green color removing machine for tea pulverizing mill

A technology of greening machine and tea powder, which is applied in the direction of tea processing before extraction, can solve the problems of high cost, and achieve the effects of improving quality, improving circulation efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

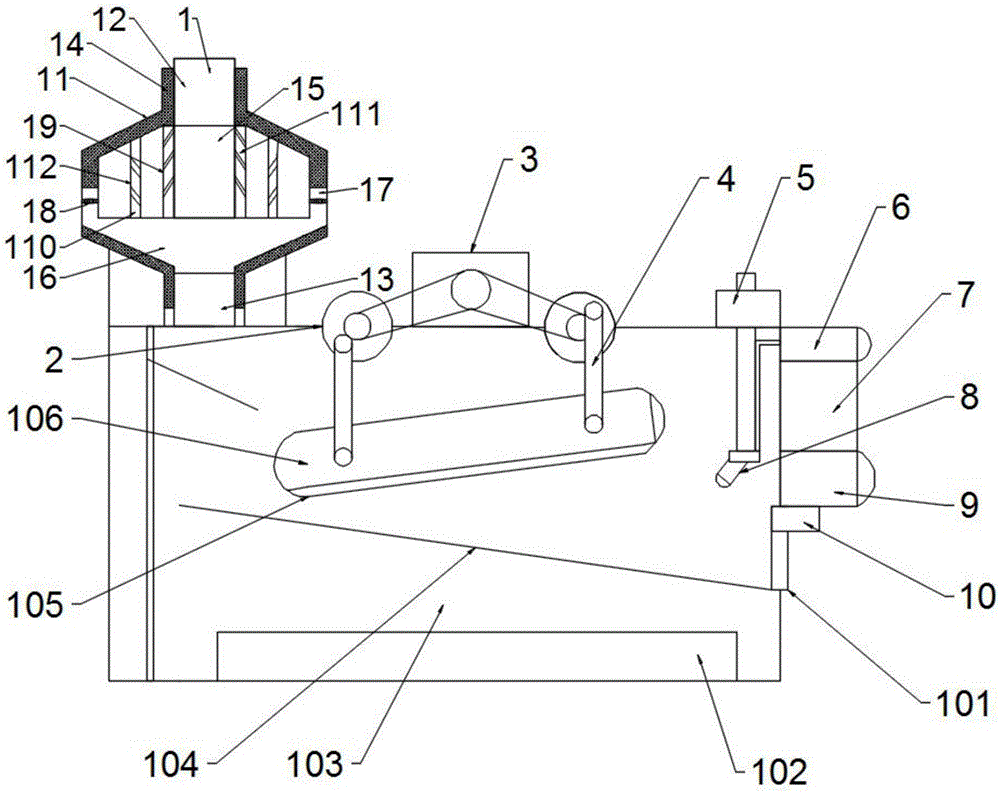

[0016] see figure 1 , a tea powder machine roughing machine, comprising a greening machine frame 103, a microwave generator 102, an inclined discharge plate 104, a drive motor 3, an eccentric wheel 2, a drive connecting rod 4, a sieve bucket 106 and an inlet The feeder 1; the feeder 1 includes a housing 11, and a feed end 12 and a discharge end 13 are respectively formed at the upper and lower ends of the housing 11, and the housing 11 is connected to the feed end 12 and the discharge end. A movable rotating shaft 14 is arranged between the ends 13, and one of the movable rotating shafts 14 is connected with the drive motor; the inside of the housing 11 forms a first cavity 15 communicated with the feed end 12, and communicated with the discharge end 13. The second cavity 16 of the first cavity 15 is provided with a first distribution feed ring an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com