Spiral wound reverse osmosis membrane element with high recovery rate

A technology of reverse osmosis membrane and high recovery rate, applied in the direction of reverse osmosis, semi-permeable membrane separation, membrane technology, etc., can solve the problems of further improvement of pure water flow rate and reduction of concentrated water discharge, so as to achieve high recovery rate and reduce discharge , Increase the effect of pressure-bearing contact points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

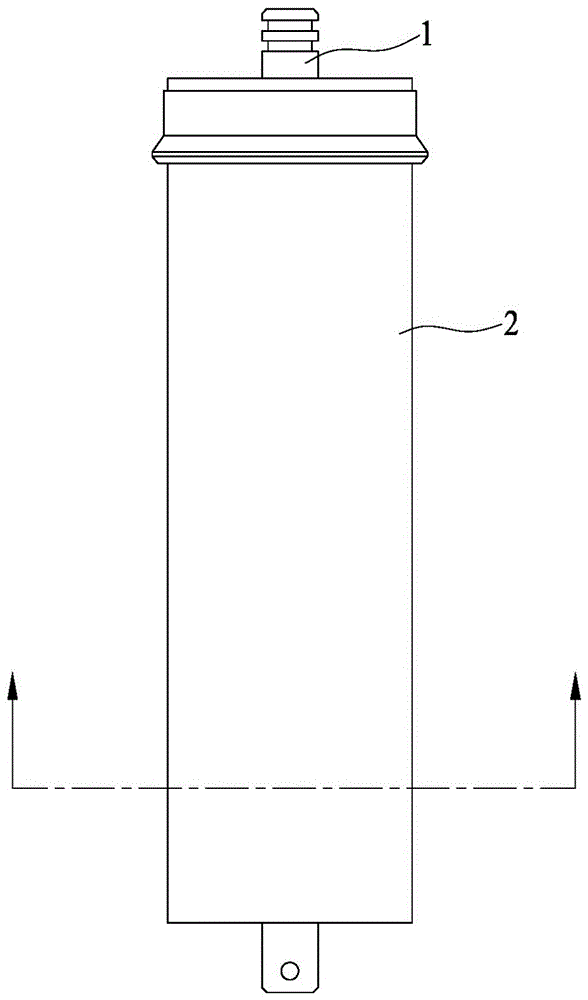

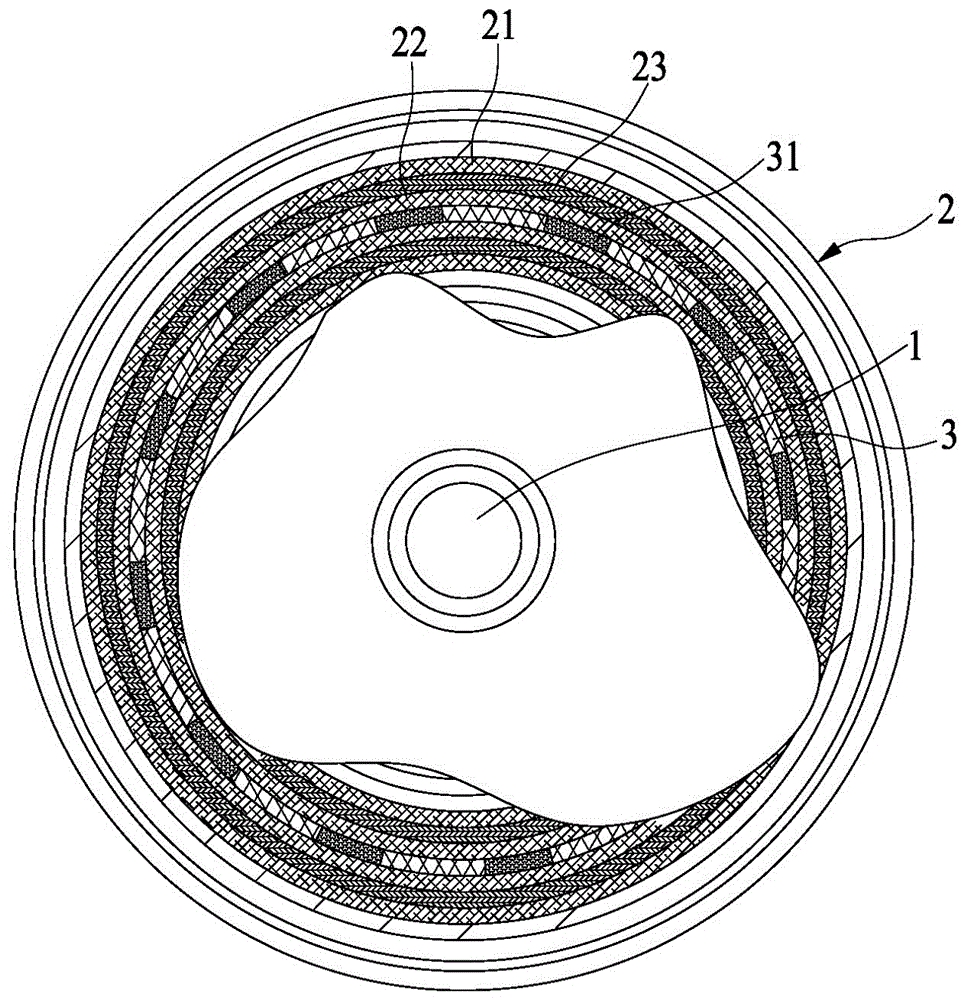

[0023] see Figure 1 to Figure 7 As mentioned above, a high-recovery roll-type reverse osmosis membrane element disclosed in the present invention includes a central pipe 1 , a membrane belt 2 and a water inlet grid 3 .

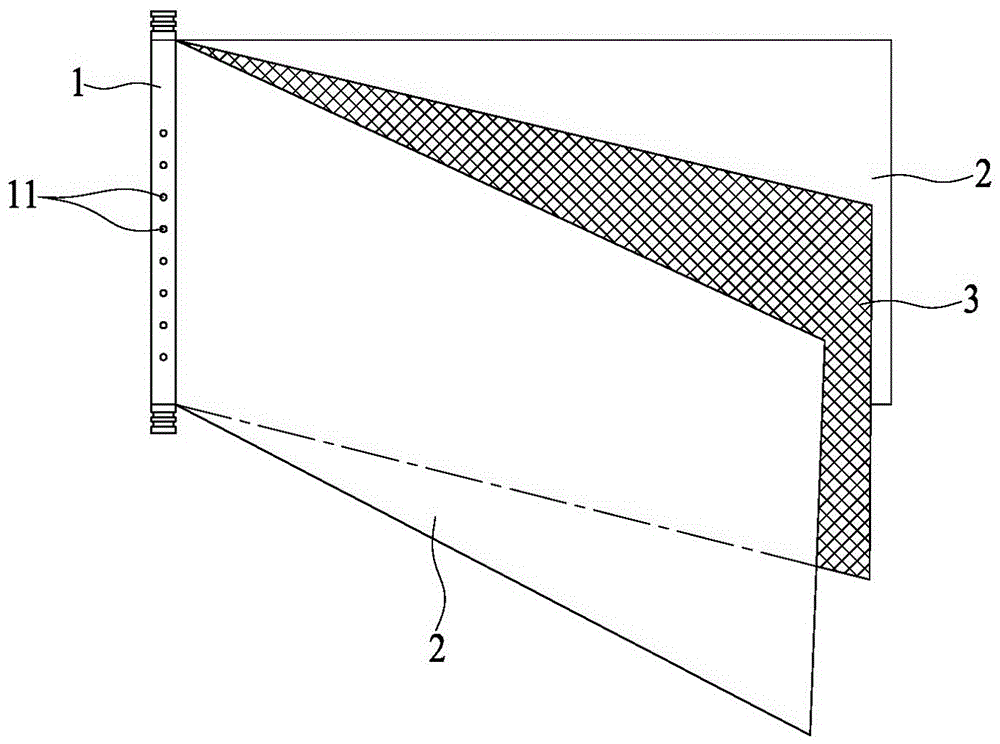

[0024] Such as image 3 As shown, a water cavity is formed in the central pipe 1, and a water hole 11 is arranged on the side wall of the central tube 1, usually a row of water holes 11 is arranged, and the water hole 11 communicates with the water cavity, and the water cavity is not shown in the figure.

[0025] The membrane belt 2 is wound on the central pipe 1, and the water inlet grid 3 is arranged between the membrane belt 2 and the membrane belt 2. The inside of the membrane belt 2 communicates with the water cavity through the water hole 11 of the central pipe 1. After the film tape 2 is wound on the central tube 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com