Device and system for achieving synchronous cleaning of inner bearing and outer bearing and use method of system

A technology of inner bearings and outer bearings, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor cleaning quality, inability to clean at the same time, and long time consumption, and reduce maintenance and repair costs , Reduce the manual workload and shorten the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

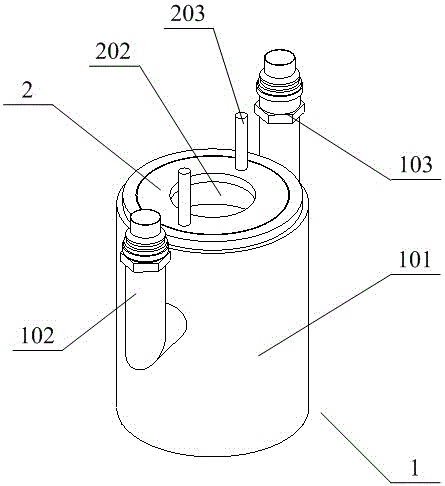

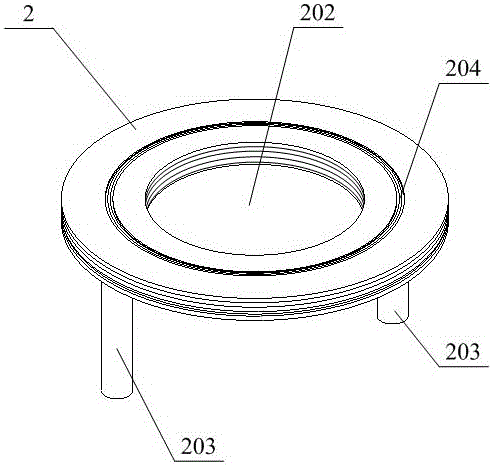

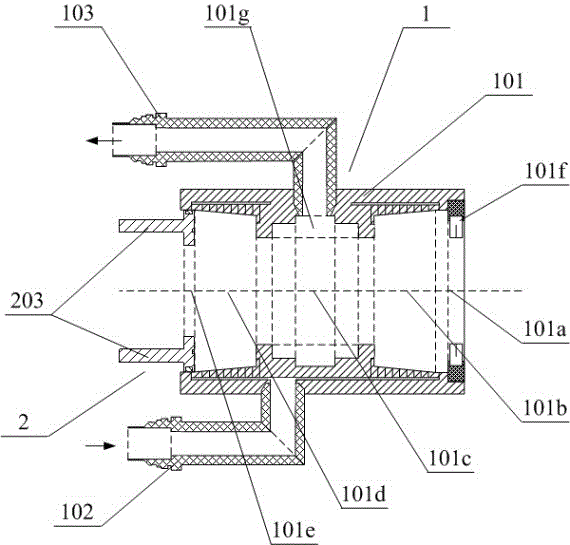

[0025] figure 1 A schematic diagram of the three-dimensional structure of the device for synchronous cleaning of inner and outer bearings provided by the present invention is shown, figure 2 A schematic diagram of the three-dimensional structure of the outer sealing cover in the device provided by the present invention is shown, image 3 A cross-sectional view of the structure of the device for synchronous cleaning of inner and outer bearings provided by the present invention is shown, Figure 4 A cross-sectional view of the application structure of the device for realizing synchronous cleaning of inner and outer bearings provided by the present invention is shown. The device for realizing synchronous cleaning of inner and outer bearings provided in this embodiment includes a cleaner 1 and an outer sealing cover 2, wherein the cleaner 1 is an integrated structure composed of a sleeve 101, an oil inlet pipe 102 and an oil outlet pipe 103 The oil inlet pipe 102 and the oil ou...

Embodiment 2

[0035] Figure 5 A schematic structural diagram of a system for realizing synchronous cleaning of inner and outer bearings provided by the present invention is shown. This embodiment provides an application system using the device for realizing synchronous cleaning of inner and outer bearings as described in the first embodiment. In addition to the device for realizing synchronous cleaning of inner and outer bearings described in the first embodiment, it also includes an oil storage tank 3, an oil pump 4 and an overflow Valve 5; the oil outlet 301 of the oil storage tank 3 is connected to the oil inlet end of the oil pump 4, the oil outlet end of the oil pump 4 is connected to the oil inlet end of the overflow valve 5, and the oil outlet of the overflow valve 5 The oil outlet is connected to the oil inlet 102 of the washer 1 , and the overflow end of the overflow valve 5 and the oil outlet 103 of the washer 1 are respectively connected to the oil inlet 302 of the oil storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com