Punching fixture for refrigerator lower beam

A refrigerator and punching technology, applied in the direction of piercing tools, manufacturing tools, metal processing equipment, etc., can solve problems such as easy cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

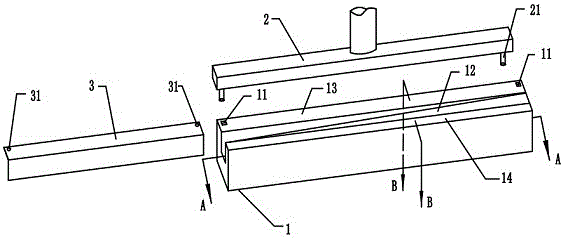

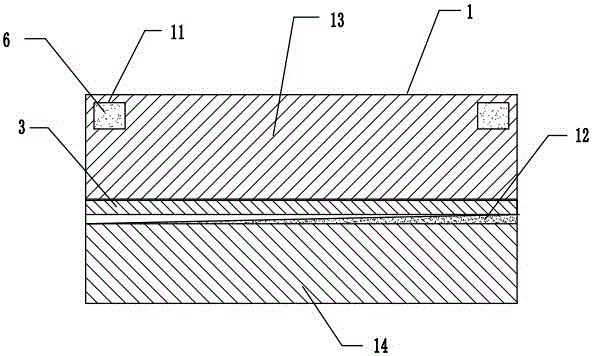

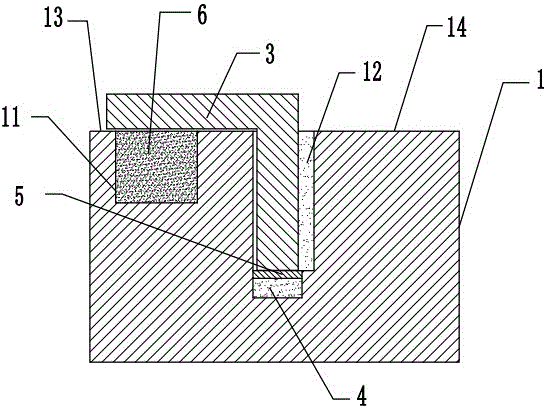

[0023] The reference signs in the accompanying drawings of the description include: punch mechanism 1, punch mechanism 2, L-shaped lower beam 3, air bag 4, rubber strip 5, ice cube 6, rectangular groove 11, elastic strip 12, punch table top 13, wedge-shaped abutment Block 14, punch 21, door reamer 31.

[0024] Such as figure 1 As shown: the punch mechanism 1 includes a punch table 13 and a wedge-shaped block 14 that stand opposite each other. A channel that can be inserted into the L-shaped lower beam 3 is formed between the punch table 13 and the wedge-shaped block 14. One end of the channel is narrow and the other end is wide, and the end of the channel is wide. The L-shaped lower beam 3 is inserted, and a rectangular groove 11 is arranged at both ends of the punch table 13, and the rectangular groove 11 is filled with ice cubes 6, and the wedge-shaped surface of the wedge-shaped block 14 is provided with a rubber elastic strip 12, and the punch press A stamping mechanism 2...

Embodiment 2

[0029] The difference from Embodiment 1 is that the ice cubes 6 in the grooves are replaced with ice water flush with the punch table 13, and then the ice water is frozen into ice cubes 6. Utilize the groove to be full of ice water and freeze into ice cube 6 again, such ice cube 6 has reduced the error between the ice cube 6 plane and the punch table 13, has guaranteed the supporting effect of ice cube 6 to L-shaped lower beam 3, prevents ice The gap between the block 6 and the punch table 13 causes non-horizontal deformation of the door hinge hole 31 after punching.

[0030] The beneficial effects of the present invention are: 1. The L-shaped lower beam is covered on the ice cube, and the ice cube can support the L-shaped lower beam. The lower beam is broken; 2. When stamping, the right-angle inner corner of the L-shaped lower beam is stuck on the right-angled edge of the punch table, and the narrower side between the wedge-shaped block and the punch table fixes the L-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com