High precision tool adjusting mechanism for lathe

A tool adjustment, high-precision technology, applied in the direction of tool holders, manufacturing tools, metal processing machinery parts, etc., can solve the problems of limited adjustment accuracy, instability, complex structure, etc., to achieve good machining accuracy, low manufacturing cost, not easy damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

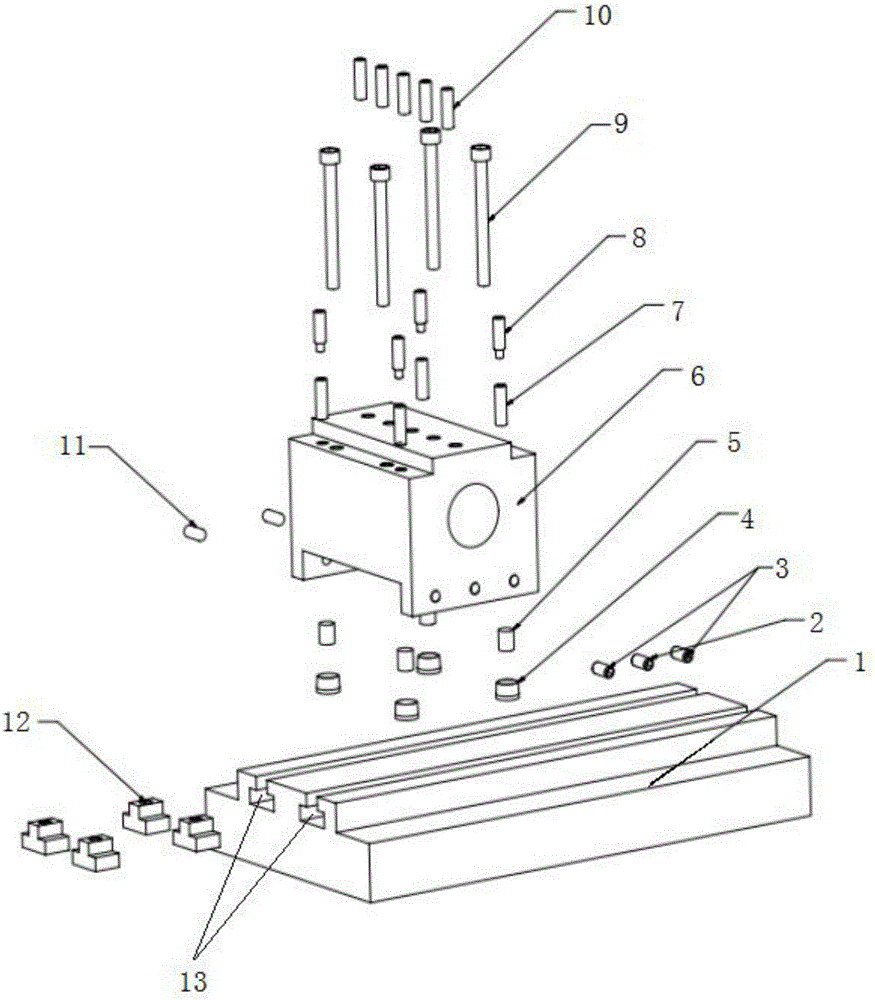

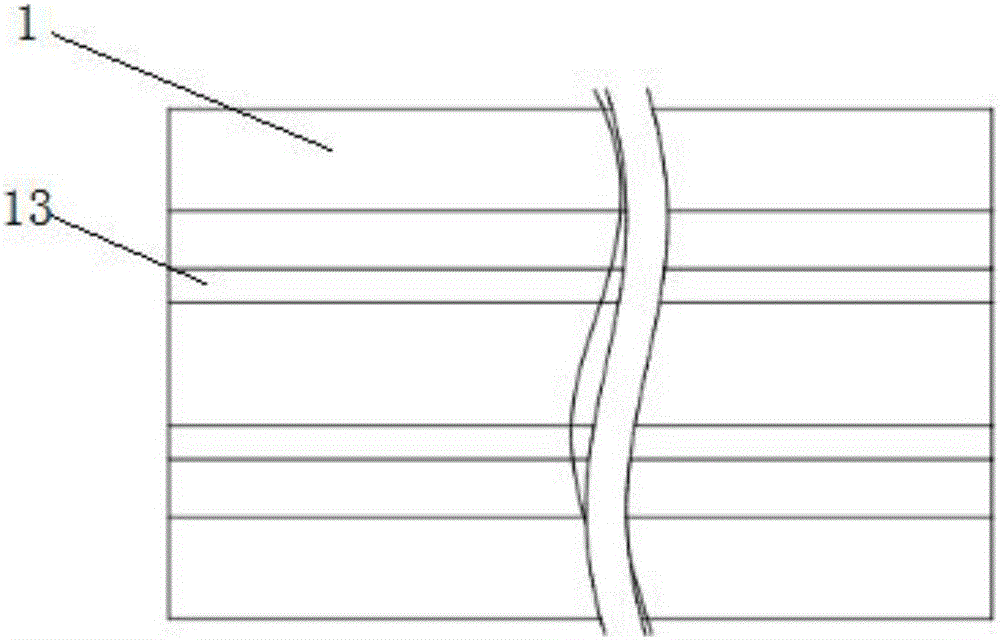

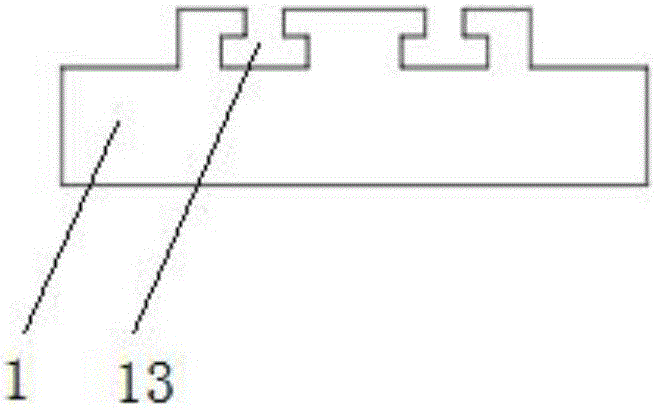

[0035] see Figure 1 to Figure 3 , the invention discloses a high-precision tool adjustment mechanism for a lathe, which includes a base plate 1 and a tool seat 6 arranged on the base plate. Two stepped grooves 13 are arranged in parallel on the base plate 1, and the stepped grooves 13 are slidingly embedded Several step nuts 12 are provided, and several sets of locking screw holes 91 and locking screws 9 that cooperate with each other are provided on the knife seat 6, and the locking screw holes 91 and locking screws 9 are arranged corresponding to the aforementioned step grooves 13. , the bottom plate 1 and the knife seat 6 are locked by locking screws 9 and stepped nuts 12 . The above-mentioned step groove 13 and the step nut 12 inside can move the locking position, which facilitates the adjustment of the position of the tool holder 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com