Method for milling and processing carbon fiber sacrifice layer of connecting plane

A processing method and a technology for connecting planes, which are applied in metal processing equipment, workpieces, milling machine equipment, etc., can solve the problems of difficult to control the thickness of parts, large deformation, and it is difficult to ensure the requirement of 0.25 contour, so as to improve the surface quality and improve the The effect of airworthiness satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

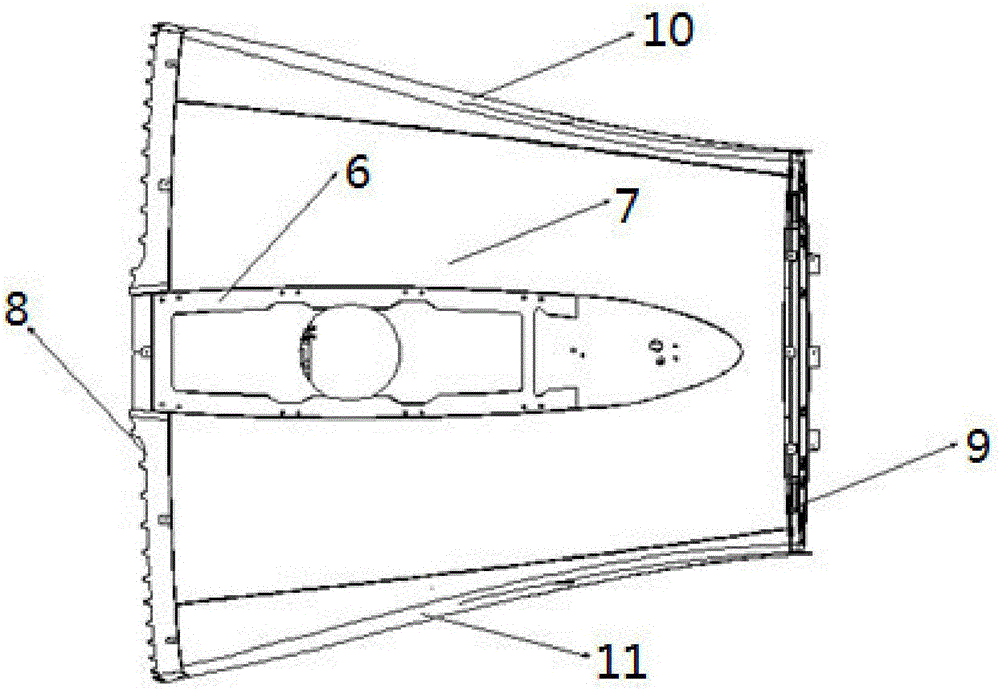

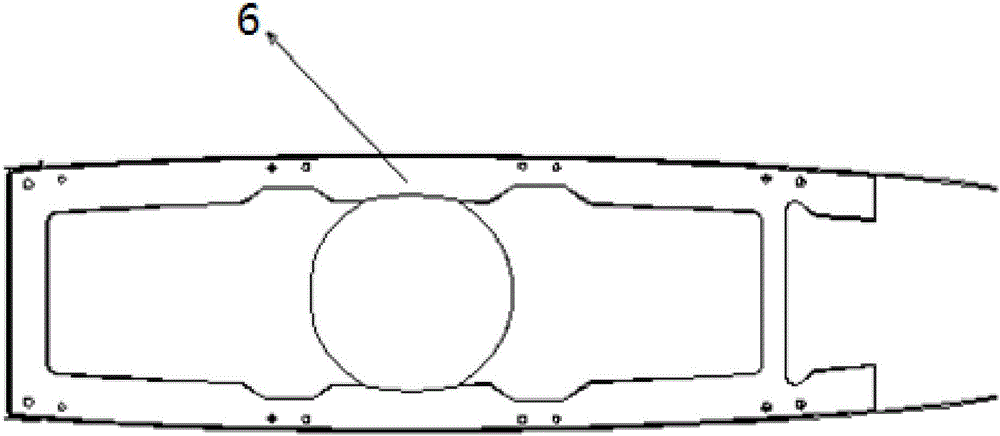

[0028] Such as Figure 1-2 As shown, the connection between the front section of the rear fuselage of the aircraft and the vertical tail adopts the method of plane docking and bolt fastening. The docking plane 6 is located on the upper surface of the upper wall plate 7 of the front section of the rear fuselage. There is a pressure frame 8 on the front side of the upper wall plate 7, and the rear There are 79 frames 9 on the side, the right side is a right wall plate 10, and the left side is a left wall plate 11. The material of the docking plane 6 is carbon fiber composite material, and the project requires that the profile of the docking plane 6 be 0.25. In order to ensure the profile requirements and ensure the smooth docking of the front section of the rear fuselage and the vertical tail, a 2mm sacrificial layer is reserved for the docking plane 6 of the project. Since the contour tolerance is only 0.25mm, and the milling area is 2 meters long and 0.6 meters wide, milling i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com