Front-end manipulator for car assembly

A technology of automobile assembly and manipulators, applied in the field of manipulators, can solve the problems of fender deformation, influence on assembly accuracy, lack of expansion ability and switching accuracy, and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

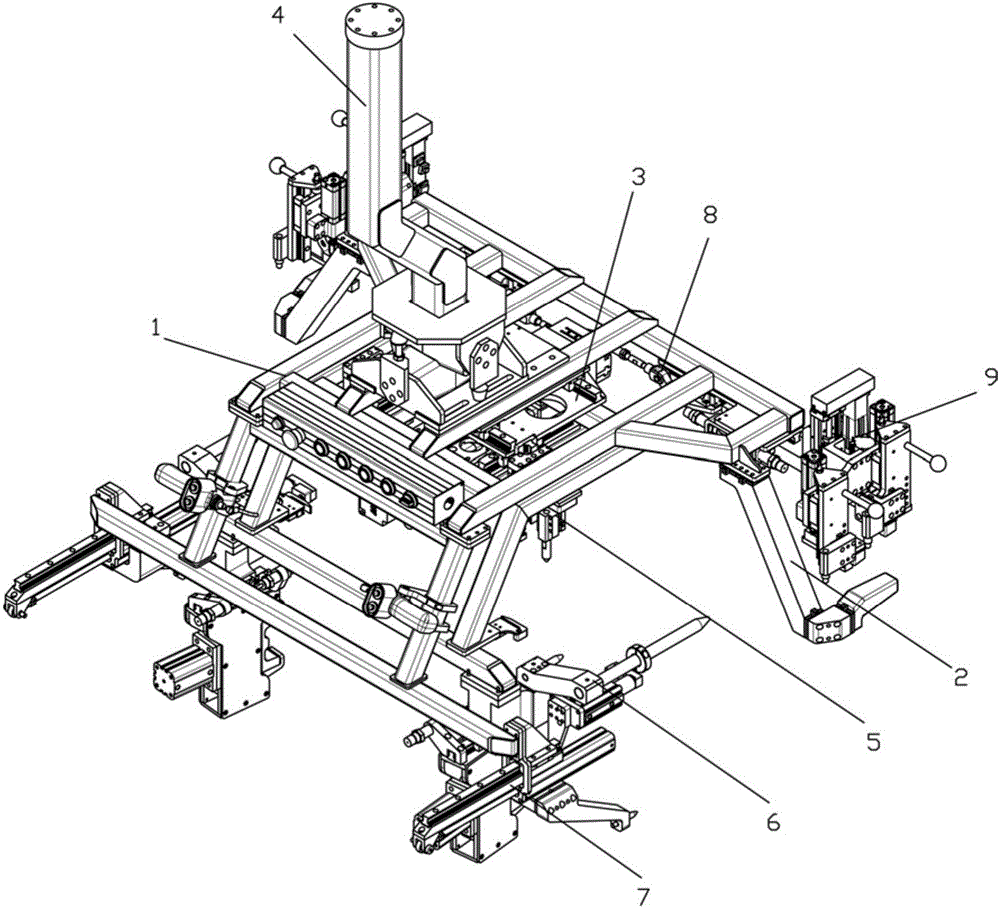

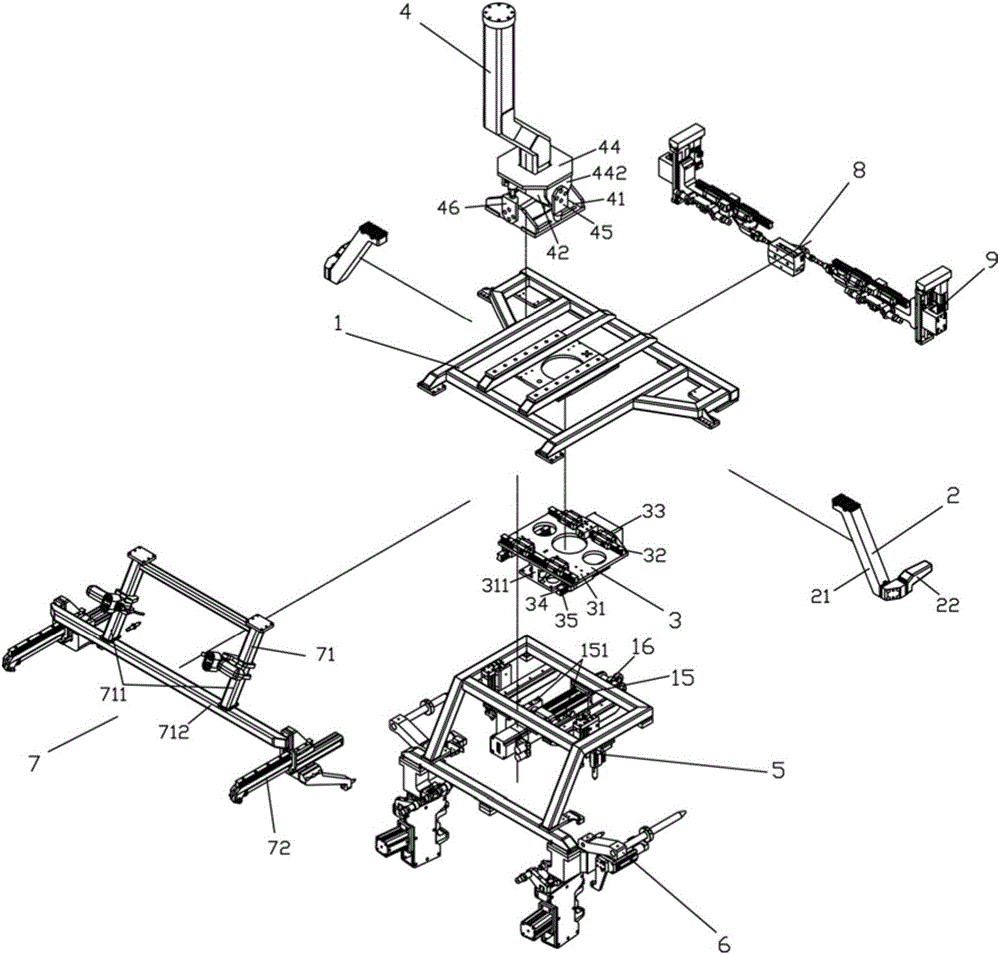

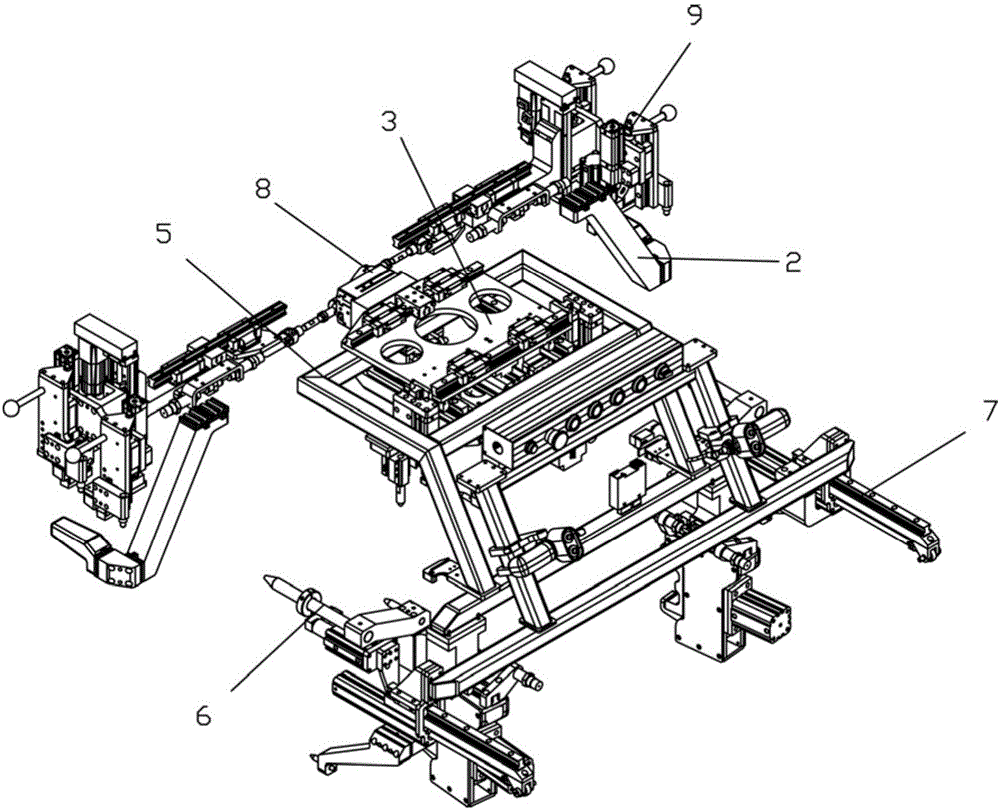

[0050] see Figure 1 to Figure 26 , a front-end manipulator for automobile assembly of the present invention, which includes,

[0051] Base 1, which is a frame structure;

[0052] Two vehicle body pre-positioning components 2 are respectively arranged on both sides of the front part of the base frame 1 structure. The vehicle body pre-positioning component 2 includes a connecting rod 21 and a positioning block 22 connected to the lower end of the connecting rod 21; the upper end of the connecting rod 21 is connected to On both sides of the front part of the frame structure of the base 1, the lower part of the connecting rod 21 is bent and extends obliquely downward, the positioning block 22 is arranged horizontally, and the rear end of the positioning block 22 is connected to the lower end of the connecting rod 21;

[0053] X-Y adjustment plate 3, set under the frame of the base 1, which includes,

[0054] The fixed plate 31 has a rectangular structure, and guide rails 32 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com