Device capable of stably clamping safety valve

A safety valve and clamping technology, which is applied in the field of devices that can stably clamp safety valves, can solve the problems of batch rework, low efficiency, and long maintenance cycle, and achieve the effect of stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

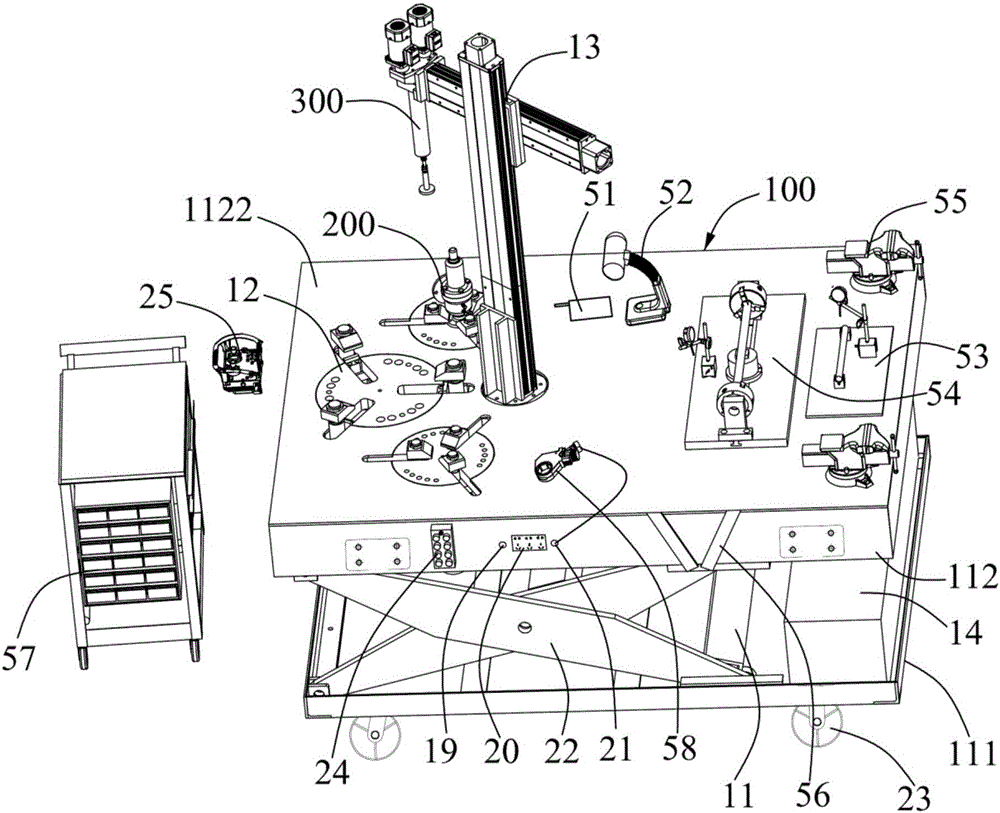

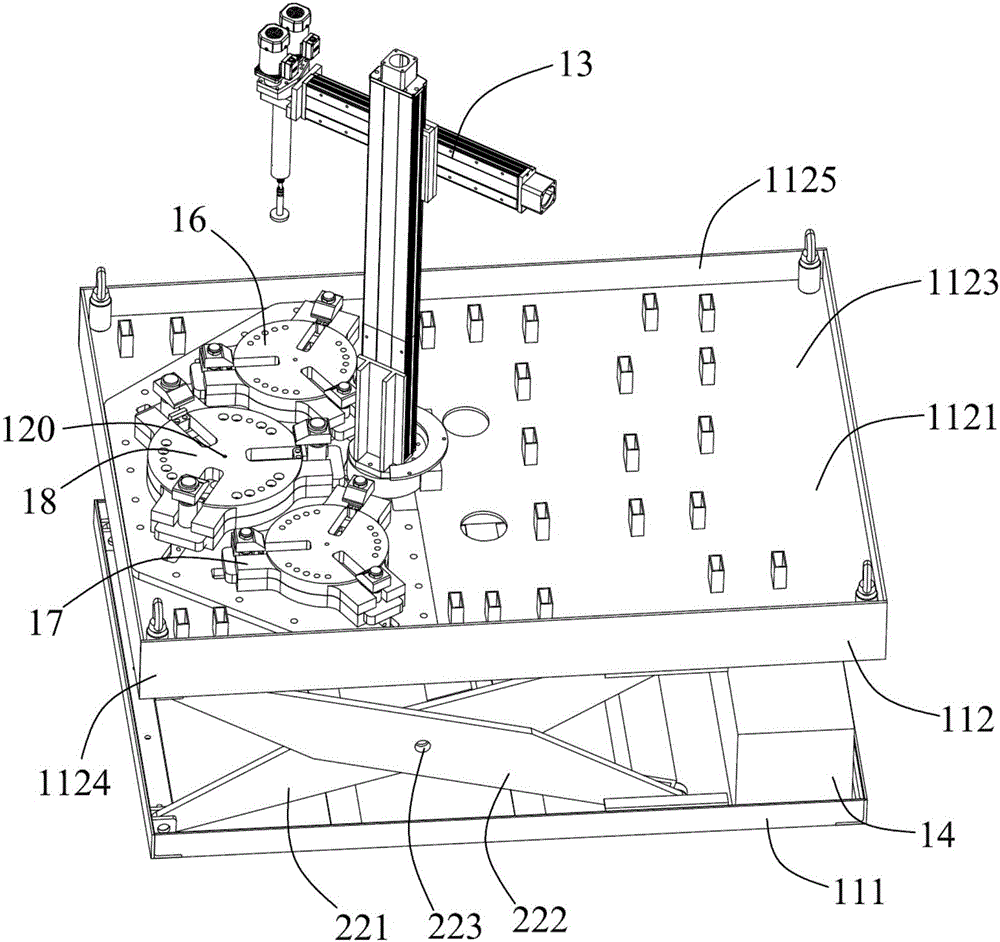

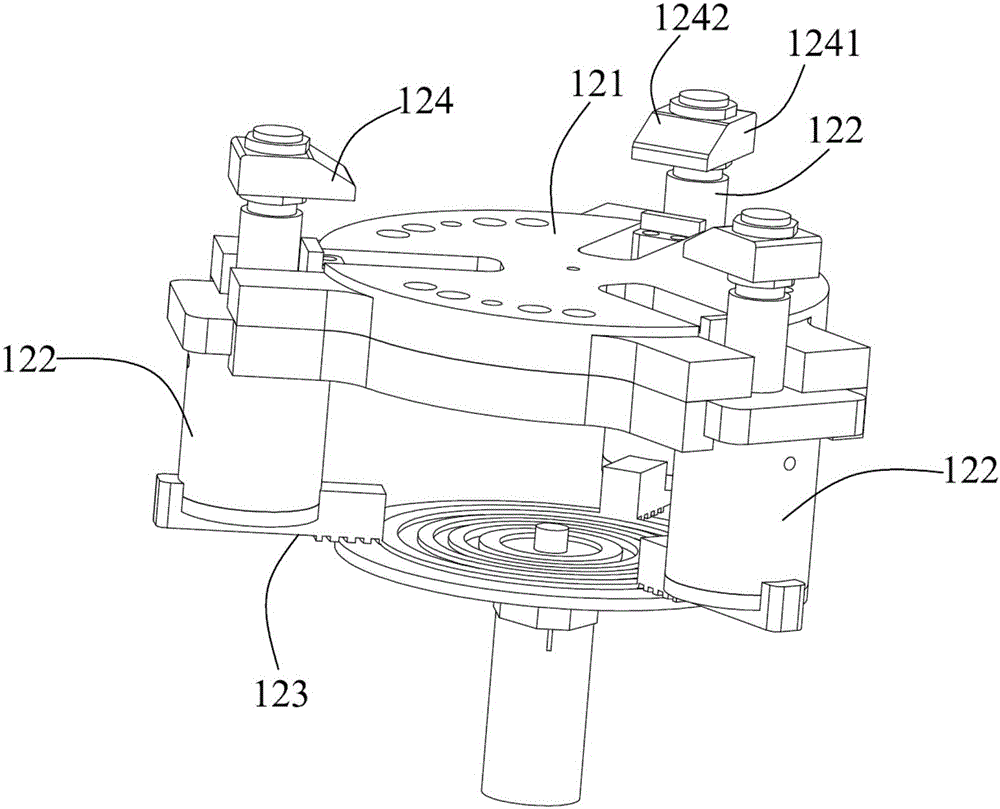

[0036] Such as Figure 1 to Figure 9 Shown is a device 100 for stably clamping a safety valve according to the present invention, which includes a lifting platform 11 , three safety valve clamps 12 and a mechanical arm 13 .

[0037] The lifting platform 11 includes a bottom 111 for being installed on the ground and a top 112 opposite to the bottom 111 , the three safety valve clamps 12 and the mechanical arm 13 are all installed on the top 112 of the lifting platform 11 . The safety valve clamp 12 is used to clamp and fix the safety valve 200 , the mechanical arm 13 is used to connect the grinding machine 300 or the turning tool 400 , and the grinding machine 300 or the turning tool 400 is used to maintain the safety valve 200 . The control of the safety valve grinder 300 is integrated on the maintenance platform, eliminating the need for an electric c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com