A pipe bracket

A technology of pipe fittings and bracket seats, which is applied in the field of auxiliary equipment, can solve the problems of increasing processing costs and reducing work efficiency, and achieves the effects of convenient and reliable adjustment, convenient reading, and large adjustment stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only provided for reference and illustration, and are not intended to limit the present invention.

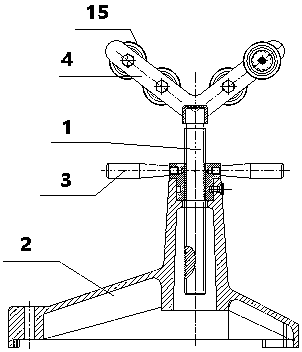

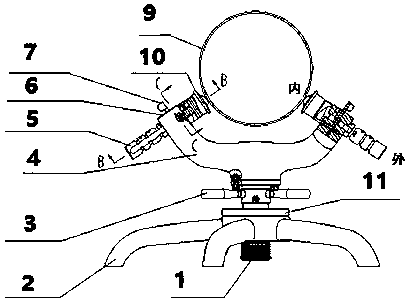

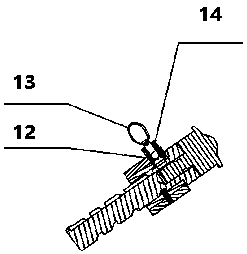

[0025] see Figure 2-4 , which is a structural schematic diagram of a preferred embodiment of the pipe fitting bracket of the present invention, which is mainly used for processing pipe fittings (including processing the tubular part of the part) with a rolling groove machine. As shown in the figure: it includes a bracket base 2, an adjusting screw 1, and a bracket base 4; The adjustment screw 1 can be adjusted axially; it is characterized in that: the two sides of the upper end support part of the bracket seat 4 have respectively obliquely connected universal ball fixed shafts 5, and the inner ends of the universal ball fixed shafts 5 are located obliquely above And be provided with the ball universal 10 that supports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com