Crane amplitude-variable wire rope anti-twisting device and method and crane

A wire rope and anti-twisting technology, applied in cranes and other directions, can solve the problems of large labor force and working time, excessive wire rope twisting force, wire rope damage, etc., to save consumption, low cost, flexible and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

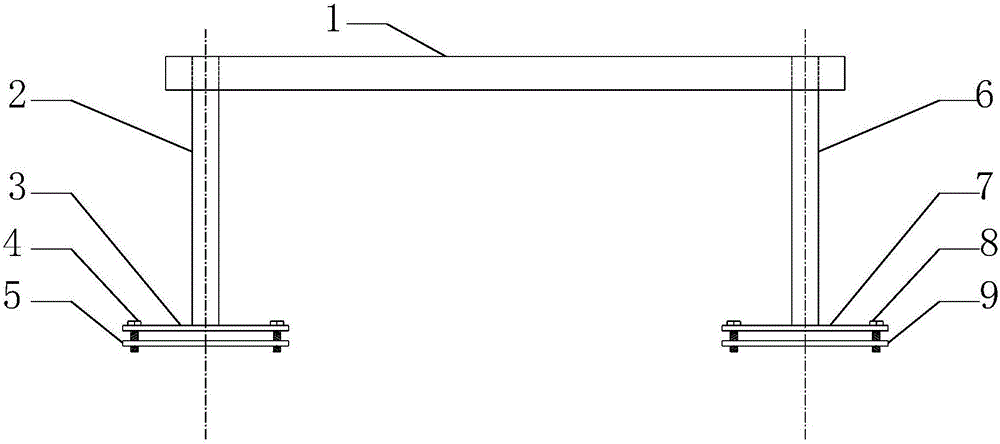

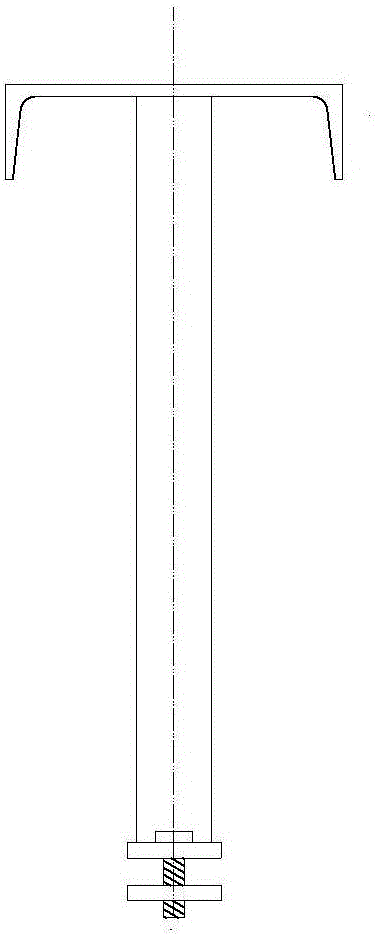

[0031] Embodiment 1: A crane luffing steel wire rope anti-twisting device, its structure is as follows figure 1 with figure 2 shown, including:

[0032] The connecting arm 1 is preferably a channel steel. The left side of the connecting arm 1 is fixedly connected with the upper end of the left steel pipe 2, and the lower end of the left steel pipe 2 is fixedly connected with the upper steel plate 3, and the upper steel plate 3 is detachably connected with the lower steel plate 5 by bolts 4. The right side of the connecting arm 1 is fixedly connected with the upper end of the right steel pipe 6, and the lower end of the right steel pipe 6 is fixedly connected with the upper steel plate 7, and the upper steel plate 7 is fixedly connected with the lower steel plate 9 by bolts 8.

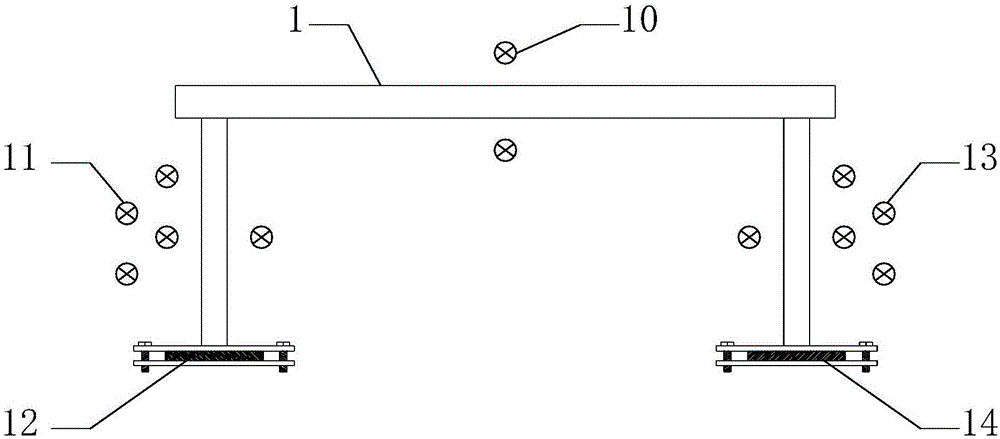

[0033] refer to image 3 As shown, during installation, the upper steel plate 3 and the lower steel plate 5 are placed above and below the left pull plate 12 of the tower crane and fastened by bolts...

Embodiment 2

[0037] Embodiment 2: A kind of tower crane, this tower crane has tower body, left movable pulley group, left luffing steel wire rope group 11, middle steel wire rope group 10, right side movable pulley group and right luffing steel wire rope group 13,

[0038] Its left side moving pulley block has left side tie plate 12, and right side moving pulley block has right side tie plate 14. Wherein, the anti-kinking device shown in Embodiment 1 is installed on the tower crane. The state after the installation is complete, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com