Method for rapidly preparing high-water reduction polycarboxylate water reducing agent at low temperature

A water-reducing polycarboxylic acid technology, applied in the field of chemical building materials, can solve the problems of cumbersome operation steps, uncertain performance of water-reducing agents, long production cycle, etc., and achieve good slurry encapsulation, easy control of the reaction process, and high efficiency. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

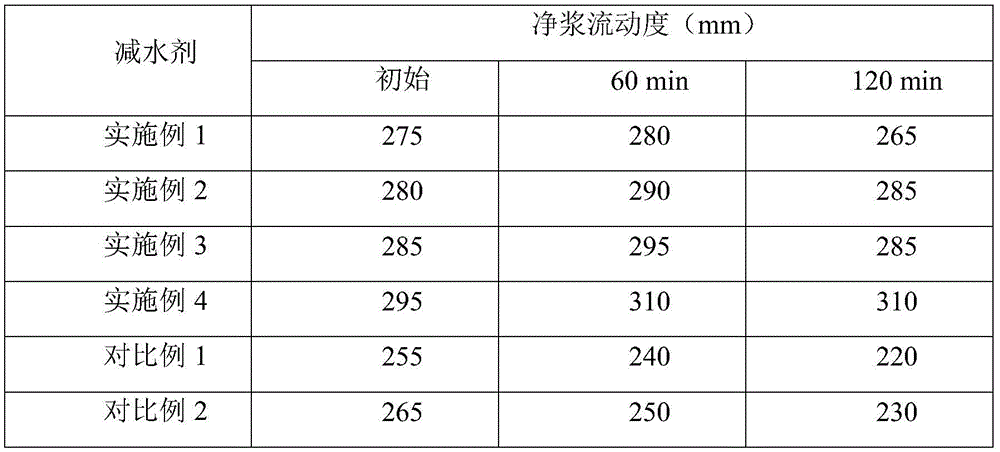

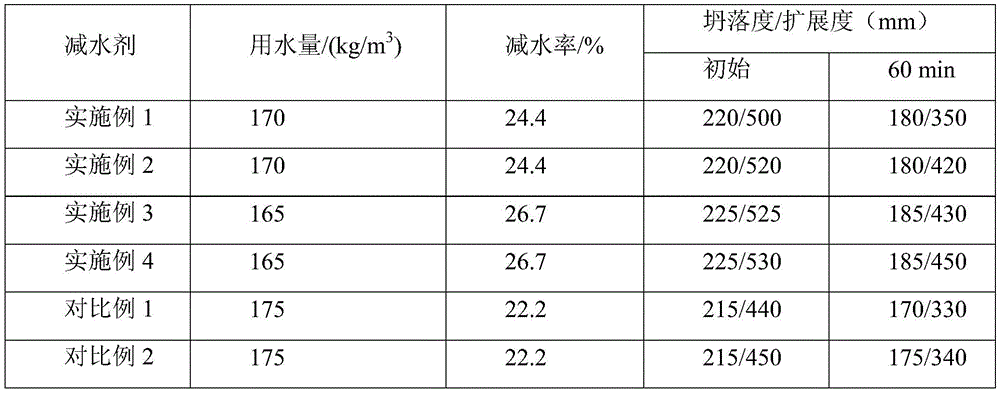

Examples

Embodiment 1

[0029] A method for rapidly preparing a high-water-reducing polycarboxylate water-reducer at low temperature, specifically comprising the following steps:

[0030] 1) Add 382.2g of solid flaky methallyl polyoxyethylene ether (molecular weight 2400), 7.8g of maleic anhydride and 390.0g of deionized water into a 1L four-necked flask and stir evenly. After the monomers are completely dissolved, add Molecular weight regulator thioglycolic acid 3.0g was stirred evenly;

[0031] 2) Add 14 g of 30% NaOH solution dropwise to the solution obtained in step 1) to adjust the pH to 4 to 5, then add 6.5 g of Fenton's reagent (4.0 g of ferrous nitrate aqueous solution with a mass fraction of 1%, and 2.5 g of hydrogen peroxide with a mass fraction of 30%) g composition), after stirring evenly, at 25°C, add dropwise the A solution made of 43.8g acrylic acid and 131.0g deionized water, and the B solution made of 26.0g20% NaOH, wherein the A solution was added dropwise in 0.5h , drop solution B...

Embodiment 2

[0034] A method for rapidly preparing a high-water-reducing polycarboxylate water-reducer at low temperature, specifically comprising the following steps:

[0035] 1) Add 380.0g of solid flake prenol polyoxyethylene ether (molecular weight 2400), 10.3g of itaconic acid and 319.0g of deionized water into a 1L four-neck flask and stir evenly. After the monomers are completely dissolved, add molecular weight Regulator mercaptopropionic acid 1.5g, stir well;

[0036] 2) Add 15 g of 30% NaOH solution dropwise to the solution obtained in step 1), adjust the pH to 5-6, then add Fenton's reagent (3.9 g of ferrous oxalate with 1% mass fraction, 1% mass fraction of sulfurous acid heptahydrate Iron 7.4g, mass fraction 30% hydrogen peroxide 3.0g composition), after stirring evenly, at 20 ℃, drop respectively the A solution that is made of 22.0g acrylic acid and 99.0g deionized water, and 25.0g20% ammonia water B solution, in which the A solution was added dropwise in 40 minutes, and the ...

Embodiment 3

[0039] A method for rapidly preparing a high-water-reducing polycarboxylate water-reducer at low temperature, specifically comprising the following steps:

[0040] 1) Add 380.0g of solid flaky 4-hydroxybutyl vinyl polyoxyethylene ether (molecular weight 2400), 9.2g of maleic acid and 254.8g of deionized water into a 1L four-necked flask and stir evenly until all the monomers are dissolved , add molecular weight regulator mercaptoethanol 1.3g and stir evenly;

[0041]2) Add 12 g of 30% NaOH solution dropwise to the solution obtained in step 1), adjust the pH to 4 to 5, then add Fenton’s reagent (13.6 g of ammonium ferrous sulfate with a mass fraction of 1%, 3.5 g of hydrogen peroxide with a mass fraction of 27%) Composition), after stirring evenly, at 10°C, A solution made of 48.0g acrylic acid and 130.0g deionized water, and B solution made of 20.0g30% KOH were added dropwise, wherein the A solution was added dropwise in 50 minutes, and the B solution was added dropwise. Drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com