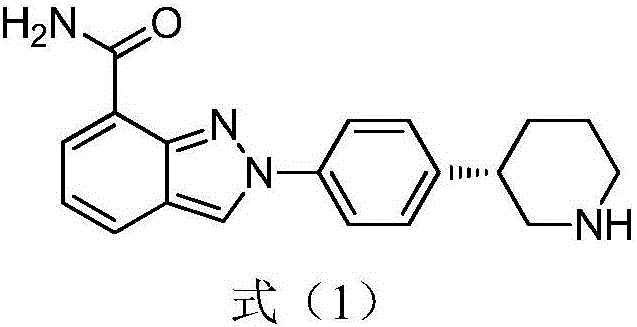

Preparation method of Niraparib intermediate 4-(3S-piperidine-3-yl)aniline

An intermediate, piperidine technology is applied in the field of preparation of anticancer drug Niraparib intermediate 4-aniline, which can solve the problems of high reaction cost, cumbersome processing, poor selectivity, etc., and achieves reduced production cost, fewer steps, and is conducive to scale. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

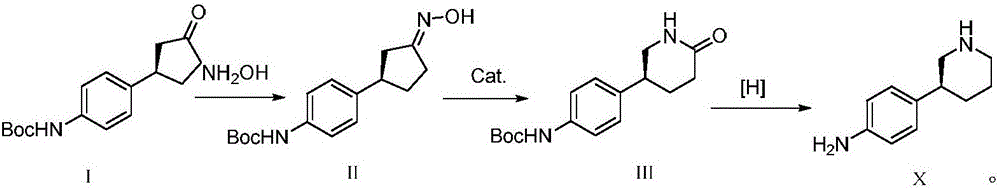

[0031] The preparation of the compound shown in formula I

[0032] Add 0.35g (1mmol) of (S)-(-)-binaphthol phosphate to ethyl acetate, then add 2.32g (12mmol) of Boc-aniline and 0.82g (10mmol) of 2-cyclopentenone to the above In ethyl acetate at 10-20°C, the reaction time is 2-3 hours, concentrated, poured into water, then extracted with ether, concentrated, recrystallized from petroleum ether, and dried in vacuo to obtain 2.58 g of the compound represented by formula I, with a yield of 93.7%. The ee value is 99.21%, and the reaction process is as follows:

[0033]

preparation example 2

[0035] The preparation of the compound shown in formula I

[0036] Add 5.2g (15mmol) of (S)-(-)-binaphthol phosphate to ethyl acetate, then add 21.3g (110mmol) of Boc-aniline and 8.2g (100mmol) of 2-cyclopentenone to the above In ethyl acetate at 10-20°C, the reaction time is 2-3 hours, concentrated, poured into water, then extracted with ether, concentrated, recrystallized from petroleum ether, and vacuum-dried to obtain 25.9 g of the compound represented by formula I, with a yield of 94.2%. The ee value is 99.41%.

preparation example 3

[0038] The preparation of the compound shown in formula I

[0039] Add 0.17g (0.5mmol) of (S)-(-)-binaphthol phosphate to ethyl acetate, then add 2.13g (11mmol) of Boc-aniline and 0.82g (10mmol) of 2-cyclopentenone In the above ethyl acetate at 10-20°C, the reaction time is 2-3h, concentrated, poured into water, then extracted with ether, concentrated, recrystallized from petroleum ether, and vacuum-dried to obtain 2.55g of the compound represented by formula I, with a yield of 92.6% , ee value 99.17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com