Integrated anti-scaling sodium hypochlorite generator device and realization method

A technology of sodium hypochlorite and anti-scaling, which is applied in the direction of cells, electrolytic process, electrolytic components, etc., can solve the problems of affecting continuous operation, reducing the operating efficiency of electrolytic cells, and greatly damaging electrodes, so as to achieve the conditions for alleviating scaling and electrolyte Smooth and unobstructed, preventing secondary fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to the sodium hypochlorite generator device of a kind of integrated anti-scaling that the present invention proposes and preferred scheme, determine implementation condition as follows:

[0040] The heater (3) of the brine heating kettle (1) is arranged inside the brine heating kettle (1); the customized brine concentration in the brine heating kettle (1) is 1% by weight, and the brine temperature is 70 ℃; the water velocity of the brine in the brine heating tank (1) is 1 m / s.

[0041] The filter material (4) in the hot brine filter kettle (2) is natural zeolite; the filling height of the filter material (4) is not greater than that of the brine heater (1) and the hot brine filter kettle (2). The adjacent upper runner port (10).

[0042] The electric power of the liquid increasing flow pump (5) is 40w, and the head is 30 meters.

[0043] There are 4 electrolytic kettles, and each electrolytic kettle is respectively connected by a liquid flow-increasing pipel...

Embodiment 2

[0049] The heater (3) of the brine heating kettle (1) is arranged inside the brine heating kettle (1) or outside the brine heating kettle (1); the brine concentration customized in the brine heating kettle (1) is by weight percentage Calculated as 2%, brine temperature is 50° C.; the water velocity of the brine in the brine heating tank (1) is 1.2 m / s.

[0050] The filter material (4) of the hot brine filter kettle (2) is an ion exchange resin; the filling height of the filter material (4) is not greater than that of the brine heater (1) and the hot brine filter kettle (2). The adjacent upper runner port (10).

[0051] The electric power of the liquid increasing flow pump (5) is 10w, and the head is 25 meters.

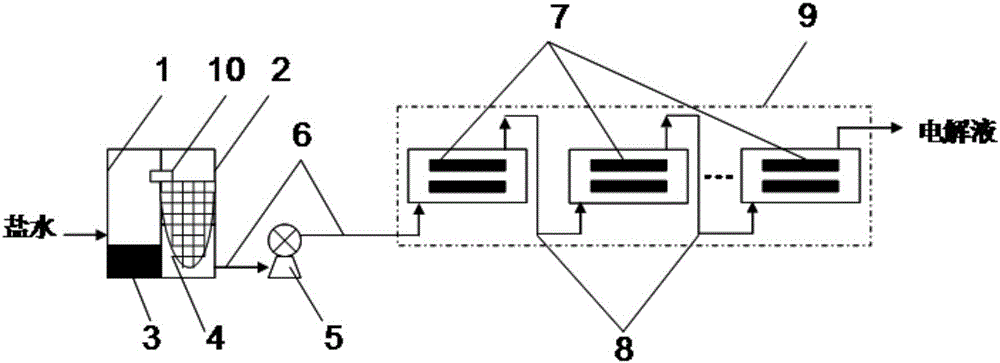

[0052] There are 4 electrolytic kettles, and each electrolytic kettle is respectively connected by a liquid flow-increasing pipeline (8) and arranged horizontally in sequence, and is constructed as a partitioned electrolytic group (9) of horizontal structure, and the ...

Embodiment 3

[0058] The heater (3) of the brine heating kettle (1) of the present invention is arranged on the outside of the brine heating kettle (1); the customized brine concentration in the brine heating kettle (1) is 3%, brine temperature It is 100 DEG C; the water velocity of the brine in the brine heating tank (1) is 1.35 m / s.

[0059] The filter material (4) of the hot brine filter kettle (2) is natural zeolite; The upper runner port (10) of the joint.

[0060] The electric power of the liquid increasing flow pump (5) is 100w, and the head is 35 meters.

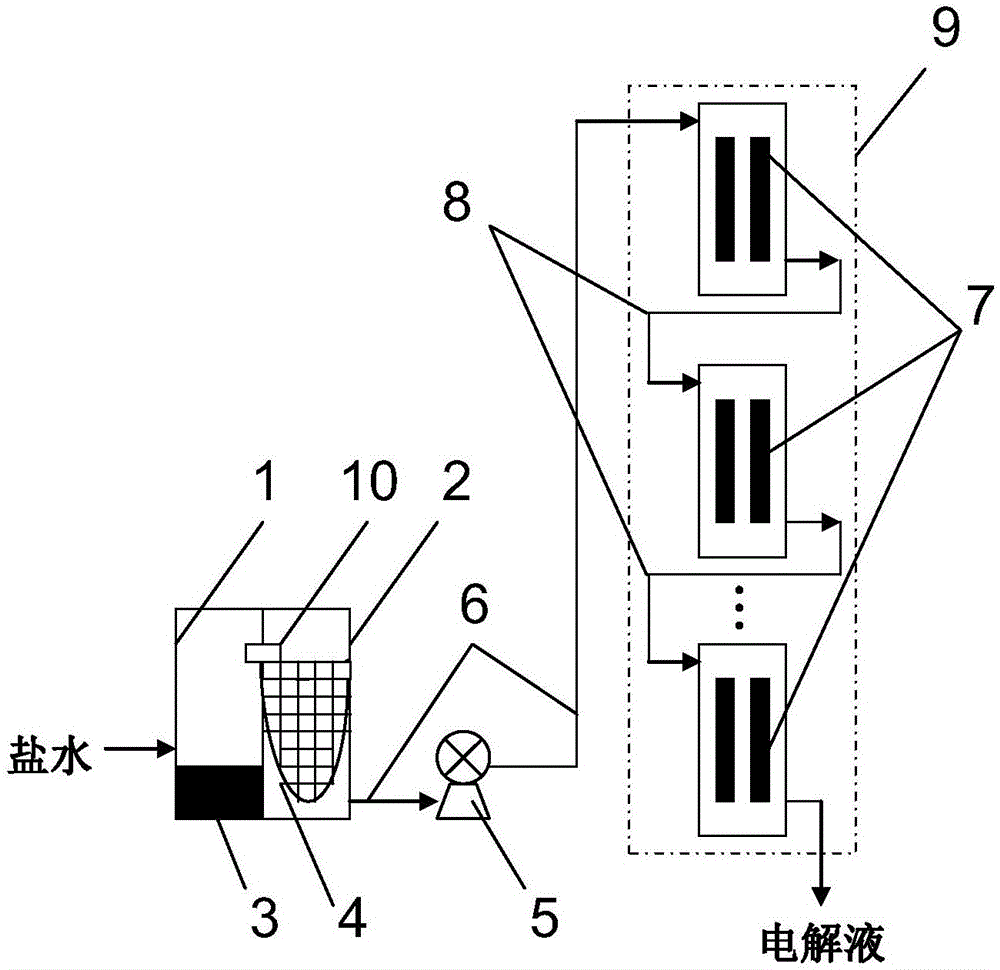

[0061] There are 4 electrolytic kettles, and each electrolytic kettle is respectively connected by a liquid flow-increasing pipeline (8) and arranged longitudinally in turn, and is constructed as a vertically structured partitioned electrolytic group (9), and the partitioned electrolytic group ( 9) The total electric power is 500w. see figure 1 .

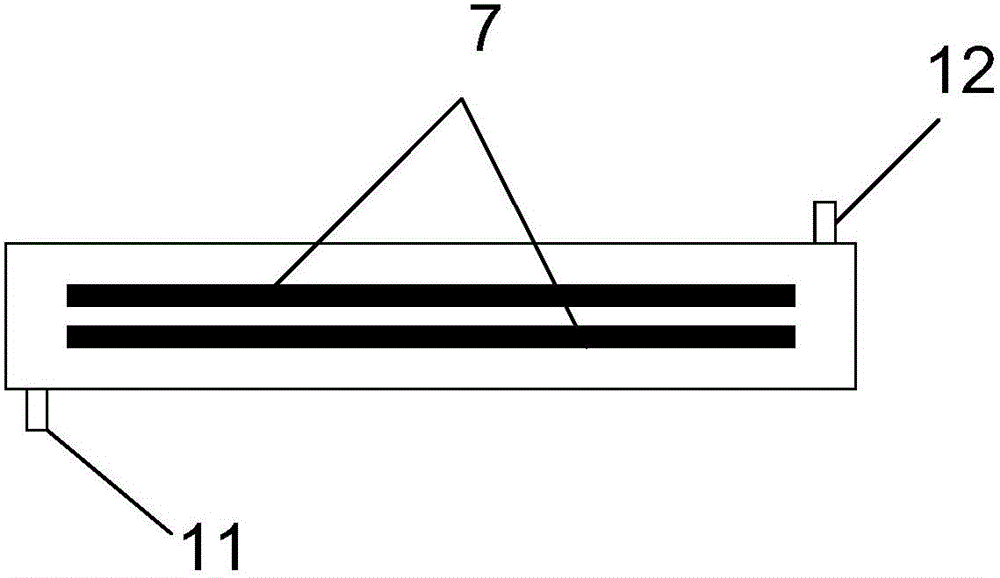

[0062] The distance between the anode plate and the cathode plate of the singl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap