Special scale inhibitor for reverse osmosis membrane water treatment system

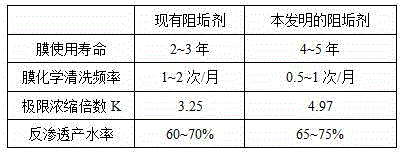

A technology for water treatment systems and reverse osmosis membranes, applied in the field of scale inhibitors, can solve problems such as deepening of water concentration polarization on both sides of the membrane, lower water production rate of reverse osmosis membranes, and increased salt concentration on the side of concentrated brine, achieving significant Scale inhibition, increase calcium tolerance, and reduce cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Prepare materials according to the following components by mass:

[0025] Hydroxyethylidene diphosphonic acid (HEDP) 1 part,

[0026] 3 parts of 2-phospho-1,2,4-butane tricarboxylate (PBTCA),

[0027] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer (AA-AMPS) 3 parts,

[0028] 13 parts of water;

[0029] (2) Mix the components in step (1) to obtain the special antiscalant for reverse osmosis membrane water treatment system.

Embodiment 2

[0031] (1) Prepare materials according to the following components by mass:

[0032] Hydroxyethylidene diphosphonic acid (HEDP) 2 parts,

[0033] 1 part of 2-phospho-1,2,4-butane tricarboxylate (PBTCA),

[0034] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer (AA-AMPS) 2 parts,

[0035] 5 parts of water;

[0036] (2) Mix the components in step (1) to obtain the special antiscalant for reverse osmosis membrane water treatment system.

Embodiment 3

[0038] (1) Prepare materials according to the following components by mass:

[0039] Hydroxyethylidene diphosphonic acid (HEDP) 5 parts,

[0040] 9 parts of 2-phospho-1,2,4-butane tricarboxylate (PBTCA),

[0041] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer (AA-AMPS) 1 part,

[0042] 15 parts of water;

[0043] (2) Mix the components in step (1) to obtain the special antiscalant for reverse osmosis membrane water treatment system.

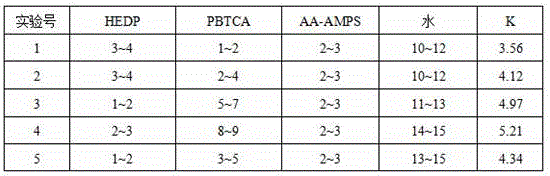

[0044] The different proportions of the components in the present invention directly affect the proportions of various groups in the scale inhibitor, and further affect the scale inhibition performance of the agent. By adjusting the mass fraction ratio of each component, the scale inhibition performance of the scale inhibitor was explored. preferred

[0045] Hydroxyethylidene diphosphonic acid (HEDP) 1-4 parts,

[0046] 1-9 parts of 2-phospho-1,2,4-butane tricarboxylate (PBTCA),

[0047] 2-3 parts of acrylic acid-2-acry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com