Combined groove-type ironing machine

An ironing machine and hybrid technology, applied in the field of ironing machines, can solve the problems of rolling, linen wrinkling, etc., and achieve the effects of good ironing quality, optimized design and excellent wrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

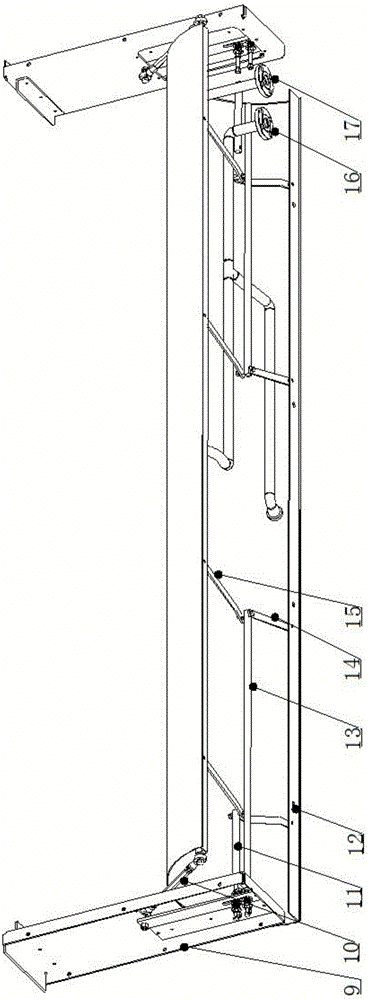

[0030] see Figure 1-Figure 5 , a hybrid trough-type ironing machine, the biggest difference from common trough-type ironing machines is that it combines the characteristics of rigid trough and flexible trough, and the rigid trough and flexible trough are used together, and the size of the rack installation is consistent. The accompanying drawings further illustrate:

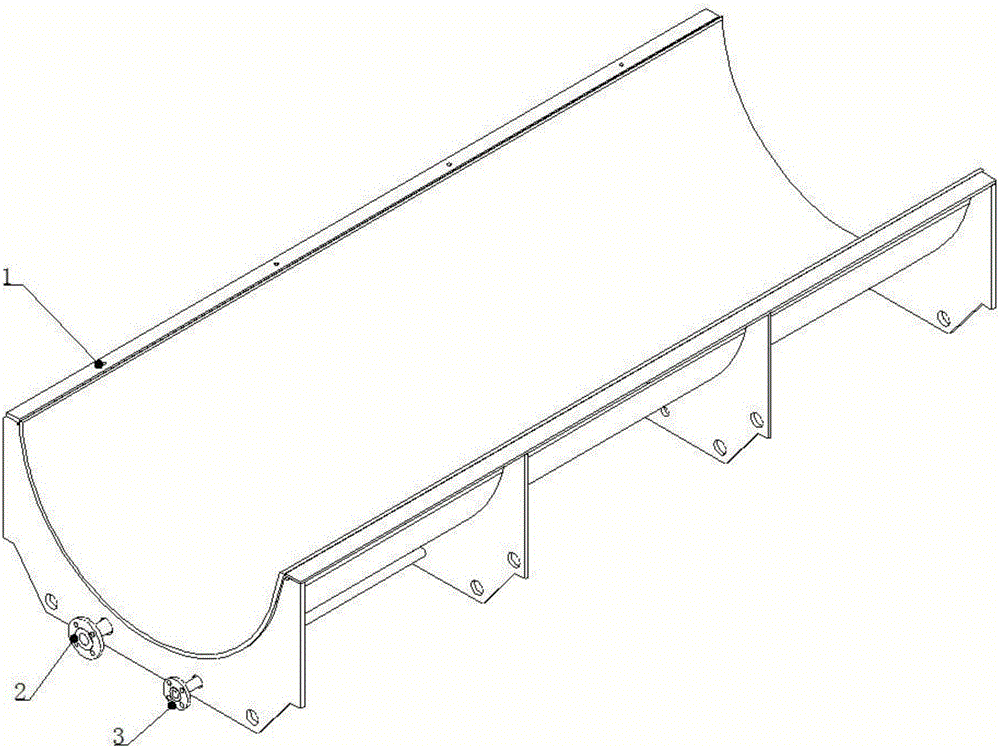

[0031] from figure 1 You can see the steam inlet 2 and the condensed water outlet 3 of the rigid tank. The steam flows through the steam chamber of the rigid tank to transfer heat to the tank body. In this picture, the linen enters from the right end and is discharged from the left end. 4 transition slot mounting holes 1, bolts 21 can be used to image 3 The corresponding transition groove installation holes 12 are connected.

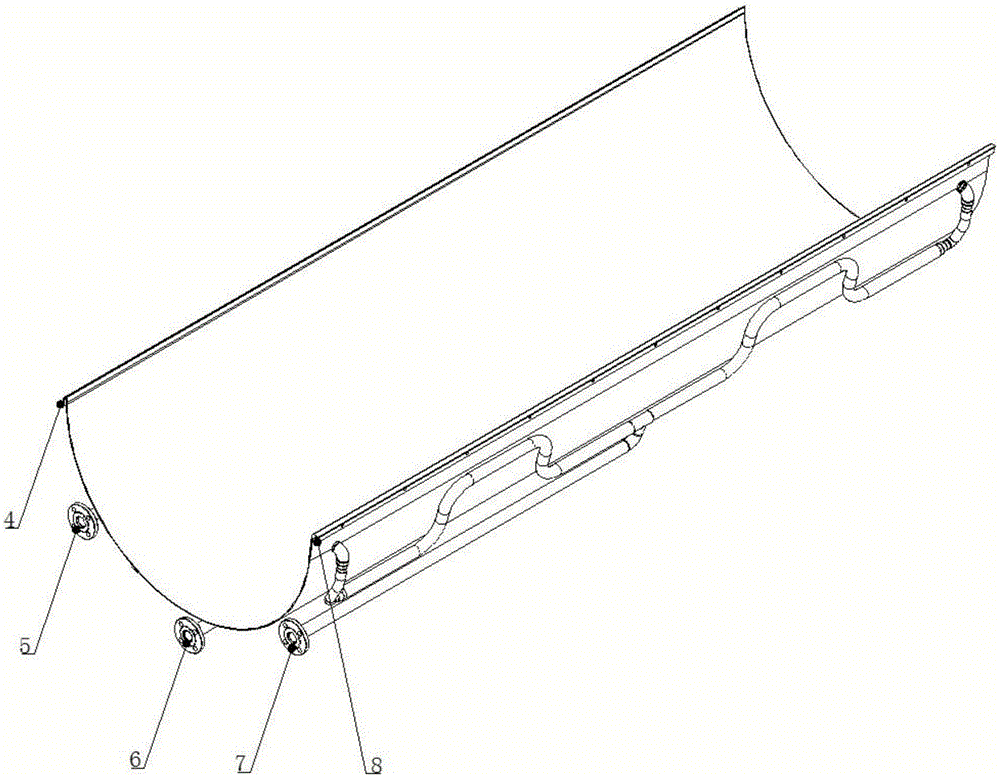

[0032] figure 2 5 and 7 in the flexible tank are the steam inlet, and 6 is the condensed water outlet. In the position shown in the figure, the left side is the discharge direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com