A Composite Structure for Restraining Reflective Cracks on Old Cement Concrete Pavement and Its Reform Method

A technology of reflecting cracks and composite structures, which is applied to roads, roads, pavement details, etc., can solve the problems of poor shear resistance, tensile strength, insufficient road surface toughness, and poor waterproof performance, so as to improve the overall bearing capacity and improve the overall Shear strength and waterproof performance, the effect of improving interlayer bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

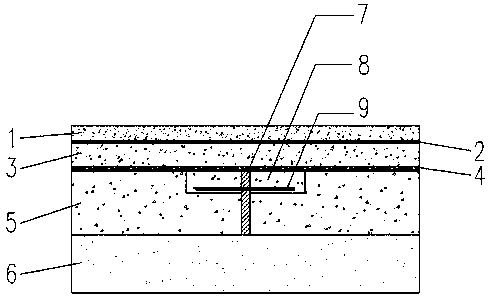

[0040] A reconstruction method for suppressing reflective cracks on an old cement concrete pavement, comprising the following steps:

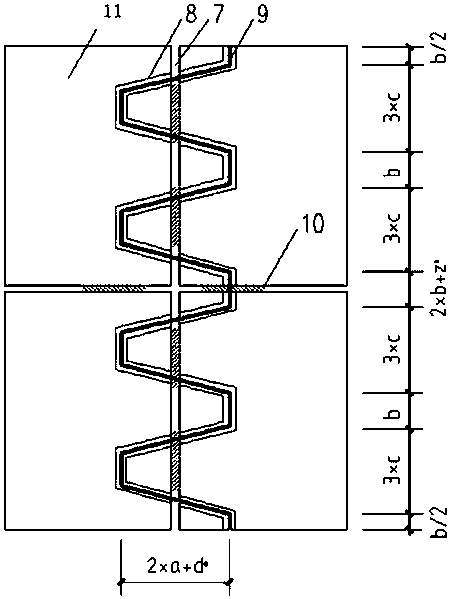

[0041] (1) Forming of broken-line local restraint steel bar 9: select threaded steel bar, bend the threaded steel bar into the required broken-line shape according to the width of the transverse joint 7 between the plates and the width of the longitudinal joint 10 between the plates, Complete the forming of the zigzag locally constrained steel bar 9;

[0042] (2) Deflection pretreatment of old cement panels 11: measure deflection difference between panels for old cement panels 11 that need joint reinforcement, and select old cement panels 11 with measured deflection difference ≤ 0.06mm;

[0043] (3) Reinforcement pretreatment: For the selected old cement panels 11 whose measured value of deflection difference is less than or equal to 0.06mm, perform pretreatment of rebar planting, and the additional stress concentration area of the vehicle lo...

Embodiment 2

[0054] The difference between Example 2 and Example 1 is that after the deflection difference between panels is measured in step (2), the old cement panel 11 whose measured value of deflection difference is > 0.06, before step (3). Cement panel 11 grouting treatment; the grouting material of the grouting treatment is cement mortar, the proportion of cement mortar is: 1.0:5, compressive strength ≥ 15Mpa, and based on the total mass of cement mortar, add 0.001wt% of aluminum powder, Early strength agent 0.01wt%. Through grouting treatment and adding aluminum powder early strength agent, etc., the deflection difference between the boards is reduced to less than 0.06mm, which reduces the additional stress caused by the void at the bottom of the board, and prevents the deflection difference between the boards from being too large, resulting in reflections on the road surface after renovation crack phenomenon.

[0055] The present invention makes full use of the residual strength o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com