Modified asphalt rapid heating system

A modified asphalt, a fast technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of poor timeliness of production and supply and poor quantity guarantee, affecting the thermal oxygen environment of modified asphalt, and inability to guarantee the quality of modified asphalt, etc. Achieve the effect of satisfying high-efficiency continuous production process, increasing temperature and avoiding aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

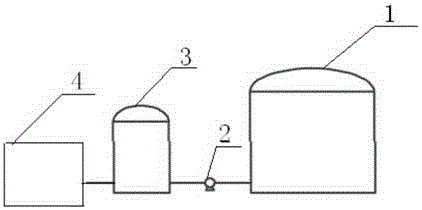

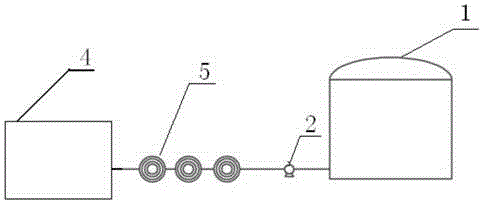

[0038] This embodiment provides an asphalt rapid heating system, such as figure 2 As shown and described, the asphalt rapid heating system includes the asphalt flow direction and sequentially connected through pipelines

[0039] Base bitumen storage tank 1,

[0040] The heat exchanger group 5 communicates with the base asphalt storage tank 1 through the circulation pump 2;

[0041] Modified asphalt production equipment4.

[0042] The 5 sets of heat exchangers include 2-3 heat exchangers.

[0043] The heat exchanger is a spiral plate heat exchanger.

[0044] The number of the heat exchangers is 3.

[0045] The heat exchange specifications of the three spiral plate heat exchangers are 150 square meters, 100 square meters and 75 square meters respectively, the rated working pressure is 1Mpa, and the working temperature is 0-350°C. In actual use, the working pressure does not exceed 0.6Mpa, and the working temperature does not exceed 250°C.

[0046] The single heat exchange...

Embodiment 2

[0054] This embodiment provides a kind of asphalt rapid heating process, which is carried out according to the following steps:

[0055] The base asphalt in the base asphalt storage tank is input to the heat exchanger group through the circulation pump;

[0056] The base asphalt that has been rapidly heated by the heat exchanger group is input to the modified asphalt production equipment for production.

[0057]The heat exchanger group is composed of 3 spiral plate heat exchangers. The heat exchange specifications of the three spiral plate heat exchangers are 150 square meters, 100 square meters and 75 square meters respectively. The rated working pressure is 1Mpa and the working temperature is 0~350℃. In actual use, the working pressure does not exceed 0.6Mpa, and the working temperature does not exceed 250°C.

[0058] The single heat exchange capacity of the three heat exchangers is 40°C, 30°C, and 20°C according to the heat exchange area from large to small. The combinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com