Transverse-direction low-yield-point energy dissipation type steel bridge anti-seismic stop block structure and arranging method

A low-yield point, energy-consuming technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of irreparable blocks, bridge beam falling beam damage, collision area damage, etc., to achieve easy detection and maintenance, prevention The effect of falling beam damage and low material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

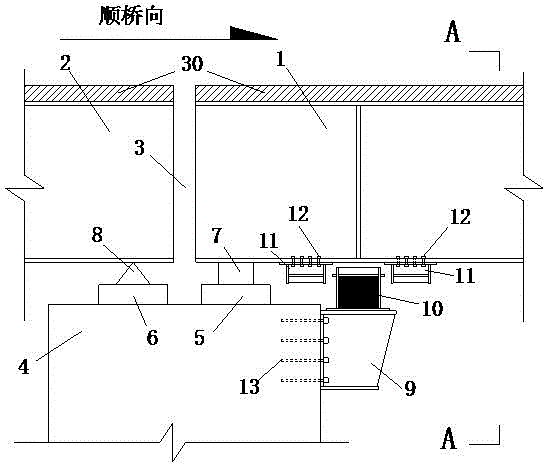

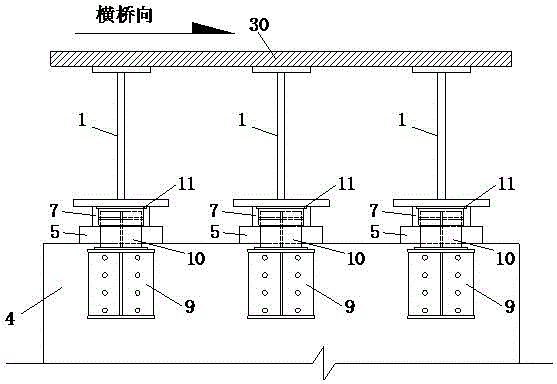

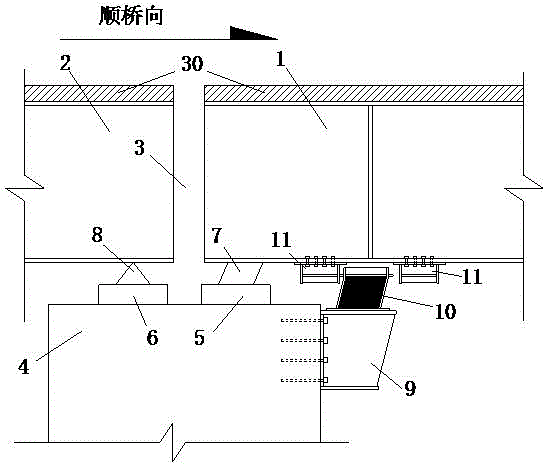

[0025] Such as Figure 1 to Figure 7 As shown, a specific embodiment of the anti-seismic block structure and arrangement method of a low-yield point steel energy-dissipating bridge along the bridge direction of the present invention, including a steel corbel 9, a block body 10 and a steel frame 11. The bridge type selected in this embodiment is an I-shaped steel plate composite girder bridge, and the bridge anti-seismic block structure and arrangement method are also applicable to other bridge types such as prestressed concrete bridges and steel bridges.

[0026] Such as Figure 1 to Figure 4 As shown, the main girder 1 of the bridge and the other main girder 2 of the bridge are disconnected at the top of the pier 4 to form an expansion joint 3 . Along the bridge direction at the expansion joint 3, on the top of the pier 4, a bridge support pad stone 5 and another bridge support pad stone 6 are set. The bridge movable support 7 is set on the bridge support pad stone 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com