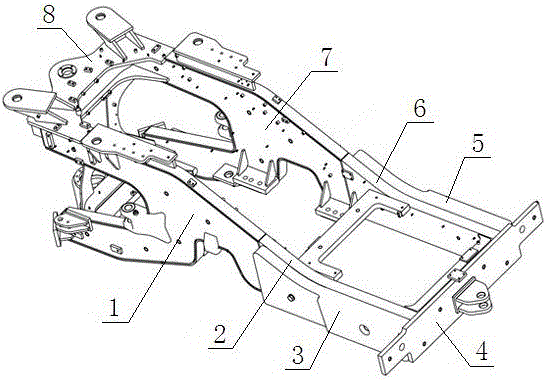

Rear frame of loader

A rear frame and loader technology, which is applied to earth movers/excavators, construction, etc., can solve problems such as difficulty in installing counterweights, labor and time, and heavy workload of welding left and right webs , to achieve the effect of saving installation space, accurate positioning, and easy installation of left and right counterweights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

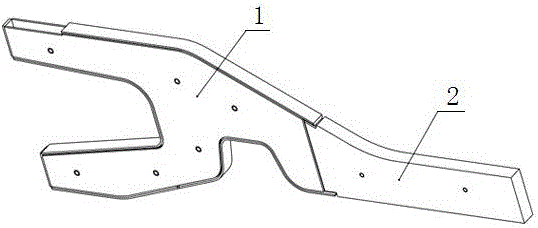

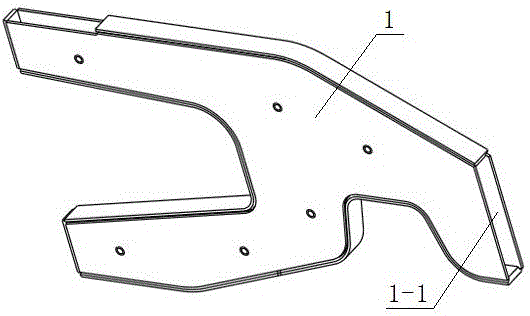

[0020] Such as figure 1 The rear frame of a loader shown includes a left web and a right web, the front of the left web and the right web are connected by a hinge seat 8, and the rear is connected by a tail plate 4 to form a frame; the left web The plate is composed of the left front web section 1 and the left rear web section 2, the rear end of the left front web section 1 is provided with a limiting groove 1-1, and the front end of the left rear web section 2 is provided with a limiting groove with the left front web section 1. The limit boss 2-1 matched with the bit groove 1-1, such as figure 2 , image 3 , Figure 4 As shown; the right web is composed of the right front web section 7 and the right rear web section 6, the rear end of the right front web section 7 is provided with a limit groove 7-1, and the front end of the right rear web section 6 is provided with the right front web section The limit boss 6-1 matched with the limit groove 7-1 of the plate section 7, s...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that: the left rear web section 2 and the right rear web section 6 of this embodiment are both integral solid cast steel, and the left front web section 1 and the left rear web section 2 The right front web segment 7 is connected to the right rear web segment 6 through the connecting plate and bolts. All the other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com