Integral lifting construction method and integral lifting construction device of veranda of multi-layer steel structure

A technology of overall improvement and construction method, which is applied in the direction of building structure, construction, and building material processing, etc., can solve the problems of slow construction speed, high construction cost, and low safety of multi-layer steel structure corridors, and achieve technical quality Improvement of management work, quality assurance of construction, and precise construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

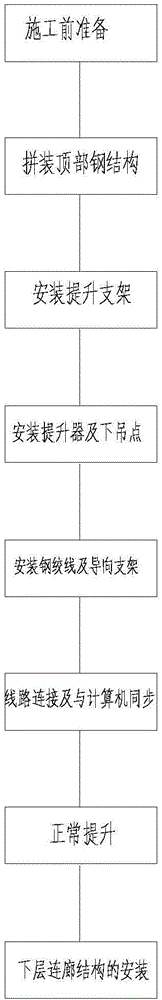

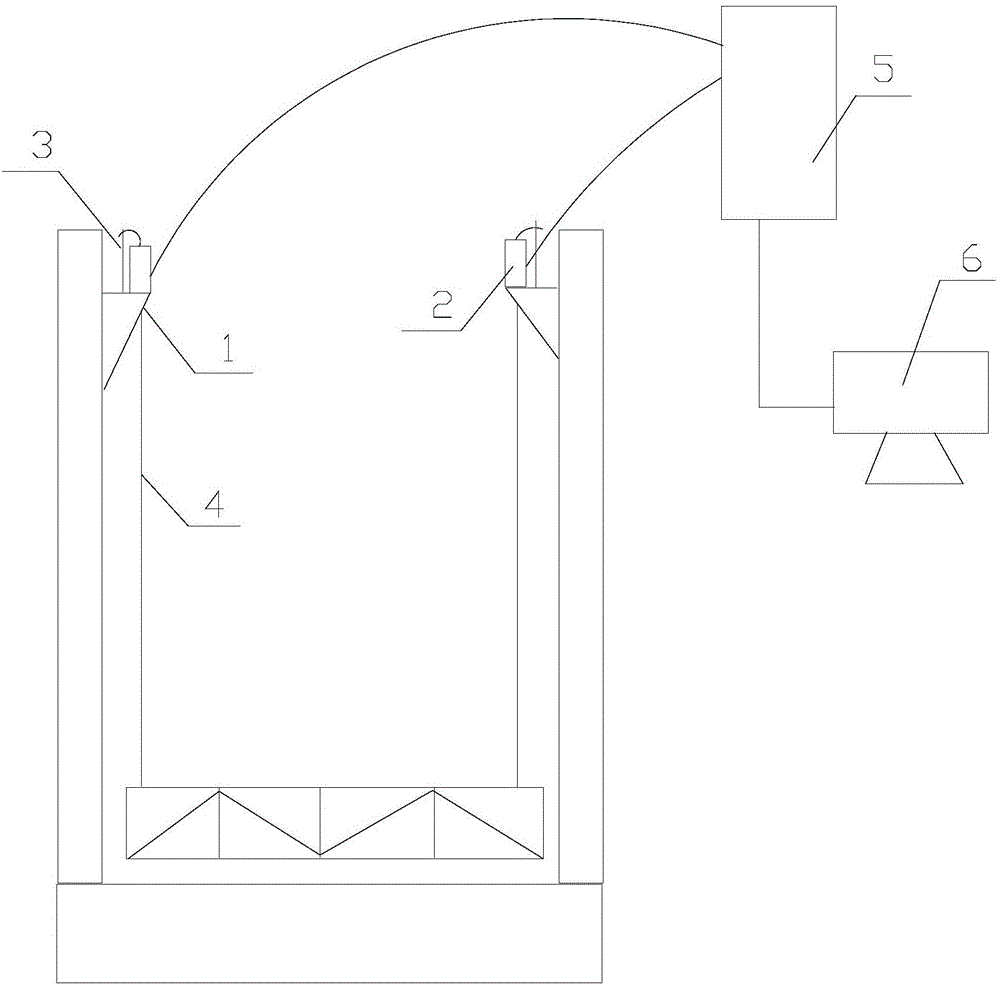

[0035] Embodiment 1: A construction method for overall lifting of a multi-storey steel structure corridor, including the following steps:

[0036] (1) Pre-construction preparation: firstly, during the construction of the main structure, the embedded parts are reserved and pre-embedded according to the requirements; then, the detailed design drawings are completed, and the processing size and splicing position of the frame are determined; finally, the lifting condition simulation is completed, and the lifting point The position and load of the lifting point are reviewed; the center of gravity of the steel structure to be lifted is located at the center of the lifting point;

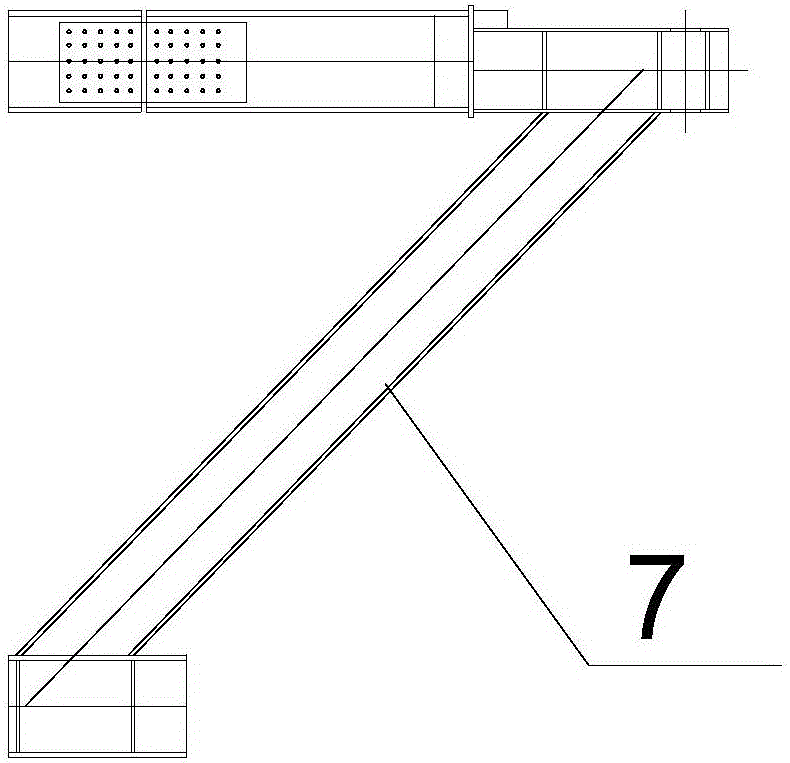

[0037] If the plane of the multi-storey steel corridor is arc-shaped, in order to prevent overturning accidents during construction, hanging points must be set outside the plane of the steel structure so that the center of gravity of the structure is located in the plane. A number of temporary rods are use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com