A composite material distribution network cross arm with phase color

A composite material and distribution network technology, applied in towers, building types, buildings, etc., can solve the problems of paint fading, material consumption, peeling, etc., to prevent air and water from entering, protect life, health and safety, and not easy to bend and deform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

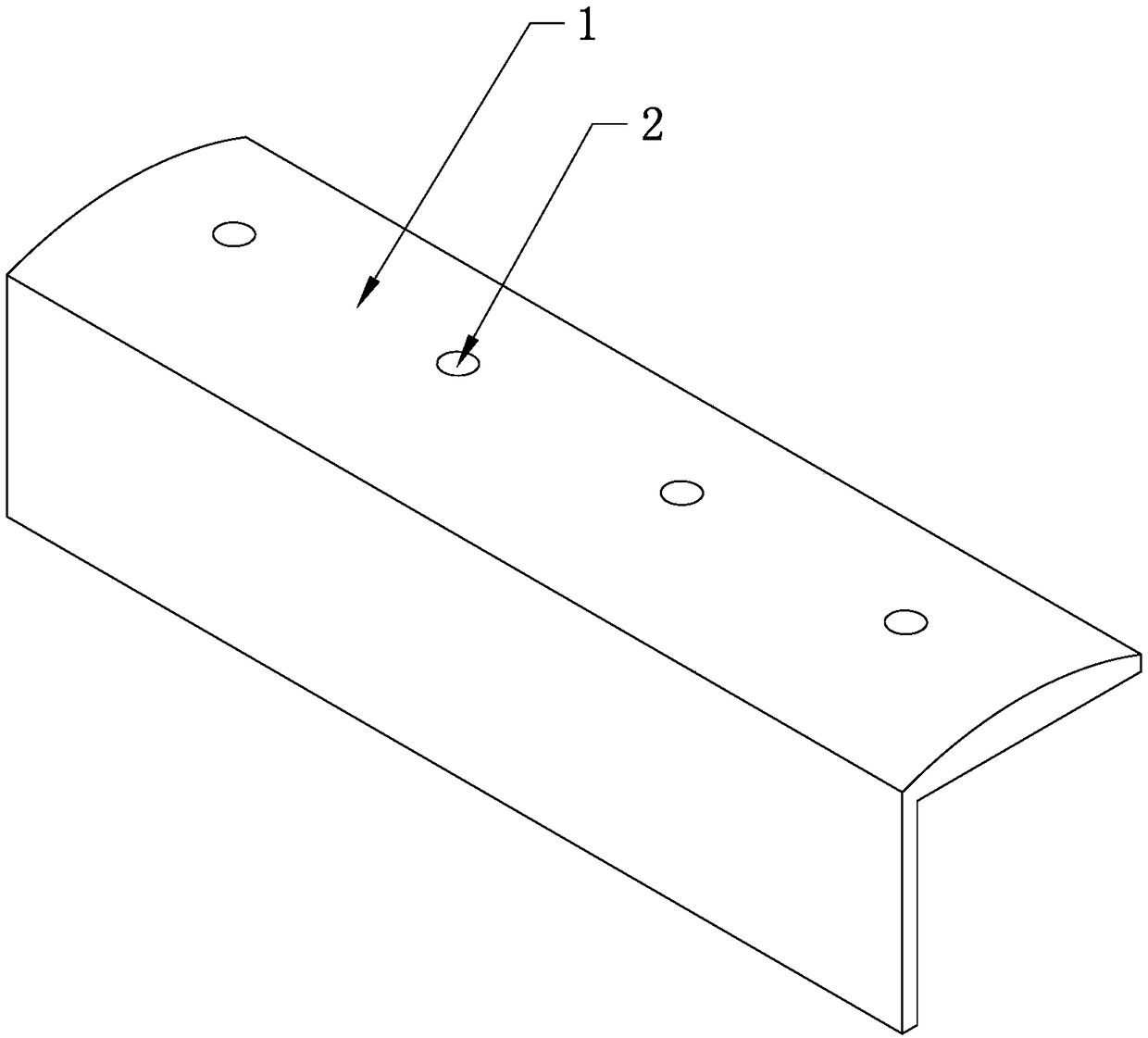

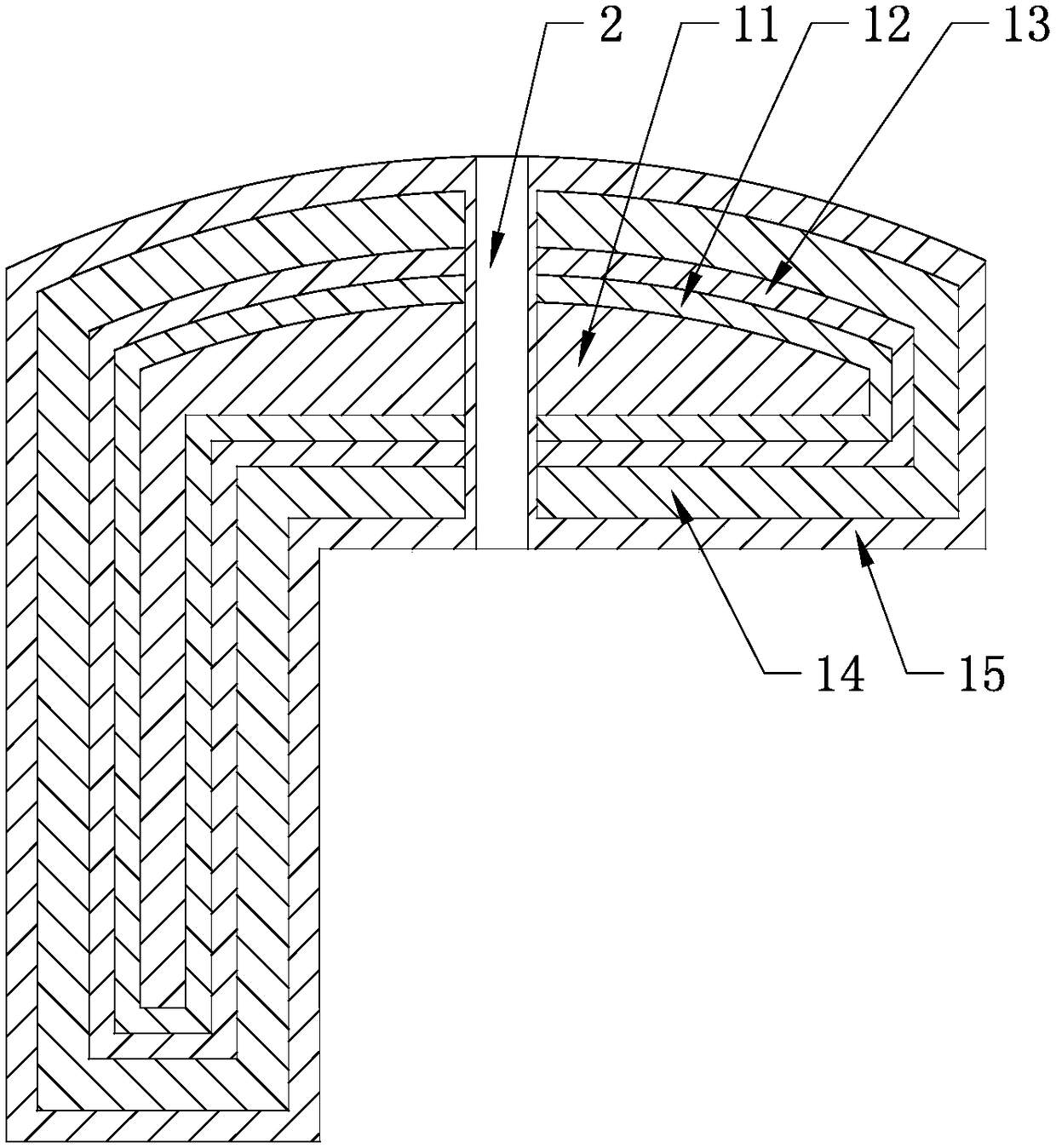

Embodiment 1

[0022] A cross-arm of composite material distribution network with phase color, comprising a base 1, on which several installation holes 2 for installing insulators are opened, the upper surface of the base 1 is an arc-shaped plane protruding upward, and the base 1 From the inside to the outside, it includes a supporting layer 11 that provides support, an anti-wear layer 13 that prevents the supporting layer 11 from being worn, a colored layer 14 with a phase color, and a protective layer that reveals the phase color of the colored layer 14 and protects the colored layer 14 15. The support layer 11 is a steel plate made of 45# steel with an "L"-shaped cross section. The wear-resistant layer 13 is a ceramic layer wrapped outside the support layer 11. A seal is injected between the wear-resistant layer 13 and the support layer 11. Glue 12 and sealant 12 are composed of the following weight percentages: 30% special resin, 20% plasticizer, 5% anti-mold thinner, 5% anti-mold agent, ...

Embodiment 2

[0030] Using the thickness of the epoxy resin plate is 5mm, the thickness of the polytetrafluoroethylene film is 0.01mm, and the thickness of the epoxy resin plate in the replacement embodiment one is 2mm, and the thickness of the polytetrafluoroethylene film is 0.02mm. The technical features are the same as those in Embodiment 1.

[0031]Epoxy resin plate with a thickness of 5mm has a very high breakdown voltage. While reflecting the color, a thick layer of protective layer is formed outside the inner steel plate, which is suitable for the erection of high-voltage transmission lines. At the same time, because the epoxy resin plate is relatively Thickness greatly meets the insulation requirement, and the thickness of the polytetrafluoroethylene film only needs to be 0.01 mm to safely protect the colored layer 14 and reduce production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com