Method for gas extraction secondary hole sealing based on swelling agent

A secondary sealing and gas drainage technology, which is applied in gas discharge, mining equipment, earthwork drilling, etc., can solve problems such as cumbersome pressurization process, poor one-time sealing effect, and unbalanced slurry pressure , to achieve the effect of improving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

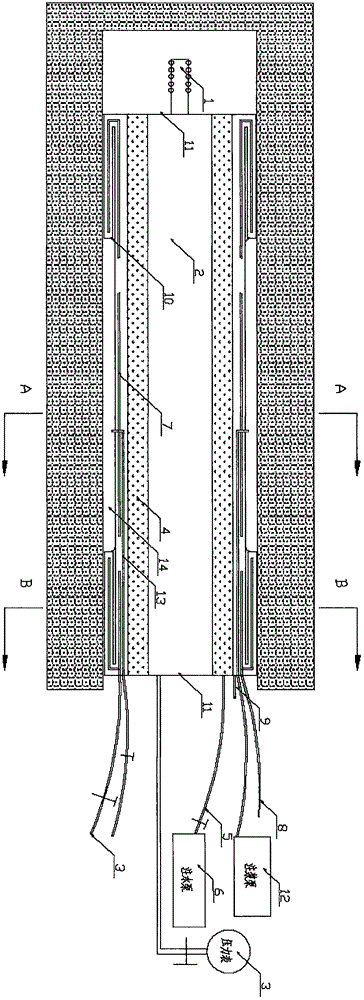

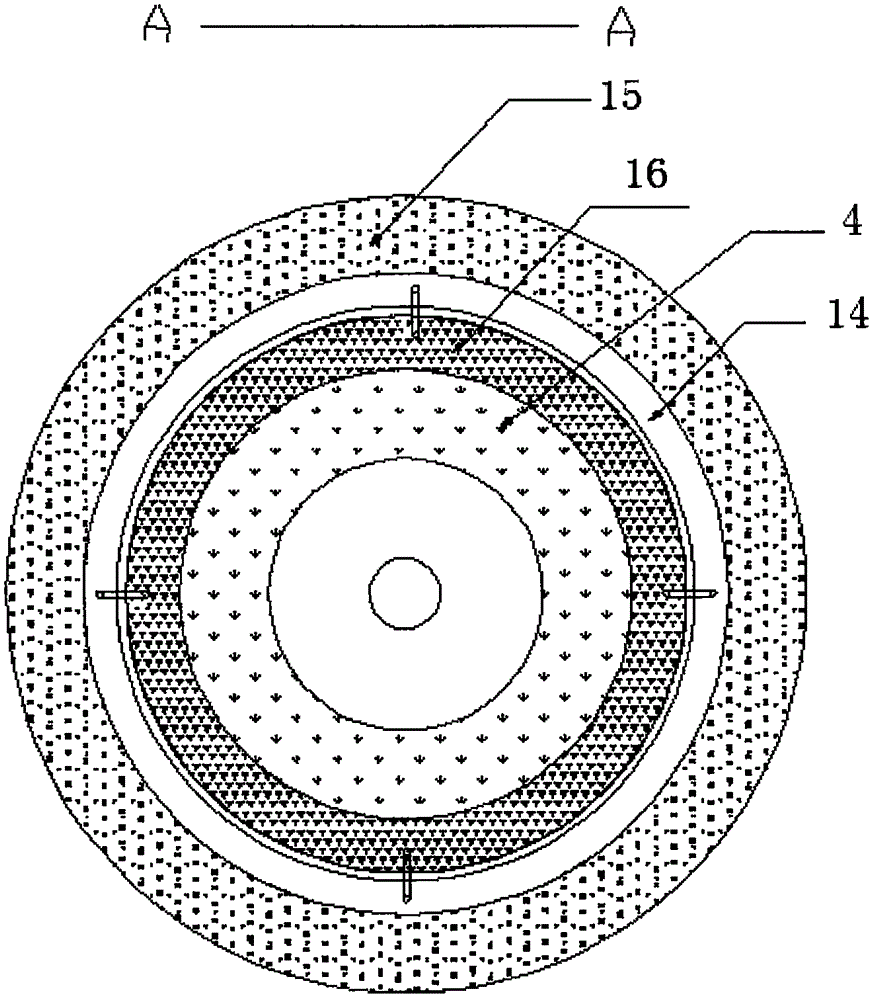

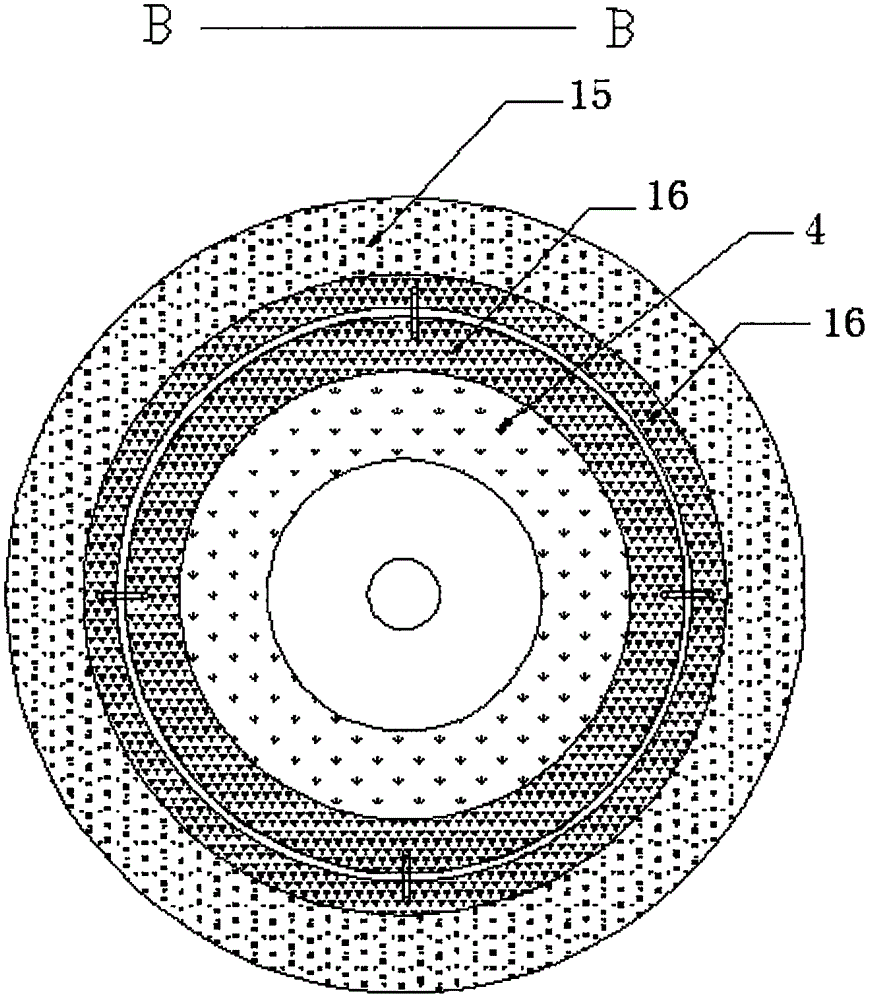

[0020] A kind of secondary sealing pressure measurement device based on expansion agent, refer to the attached Figure 1-3 , consisting of air intake flower tube 1, independent conduit 2, pressure gauge 3, high-pressure independent water bag 4, water injection conduit 5, water injection pump 6, high-pressure independent expansion bag 7, water injection pipe 8, expansion agent filling pipe 9, limit chain 10 , Limiting plate 11, grouting pump 12, grouting conduit 13, grouting cavity 14 components.

[0021] Secondary sealing and pressure measurement device based on expansion agent Sealing and pressure measurement: including the following steps: (1) The air intake flower pipe 1 is connected to the independent conduit 2, both pipes are steel conduits, and a pressure gauge is installed behind the independent conduit 2 3. The high-pressure independent water bag 4 sui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com