Hydraulic formwork trolley for rail top air duct post-pouring construction

A rail-top air duct and formwork trolley technology is applied in tunnels, tunnel linings, shaft linings, etc., which can solve the problems of poor appearance of air ducts, large workload of erecting and dismantling brackets, and high labor intensity of workers, and achieves the forming effect. Good, simple and quick assembly, less space-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

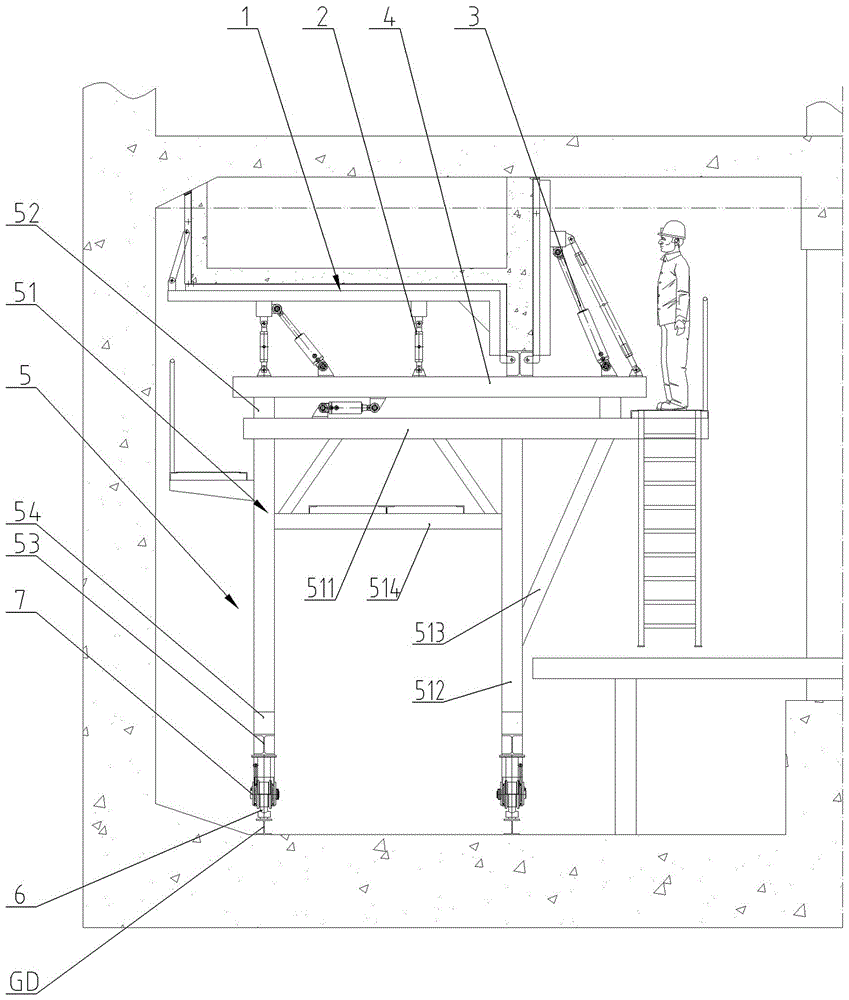

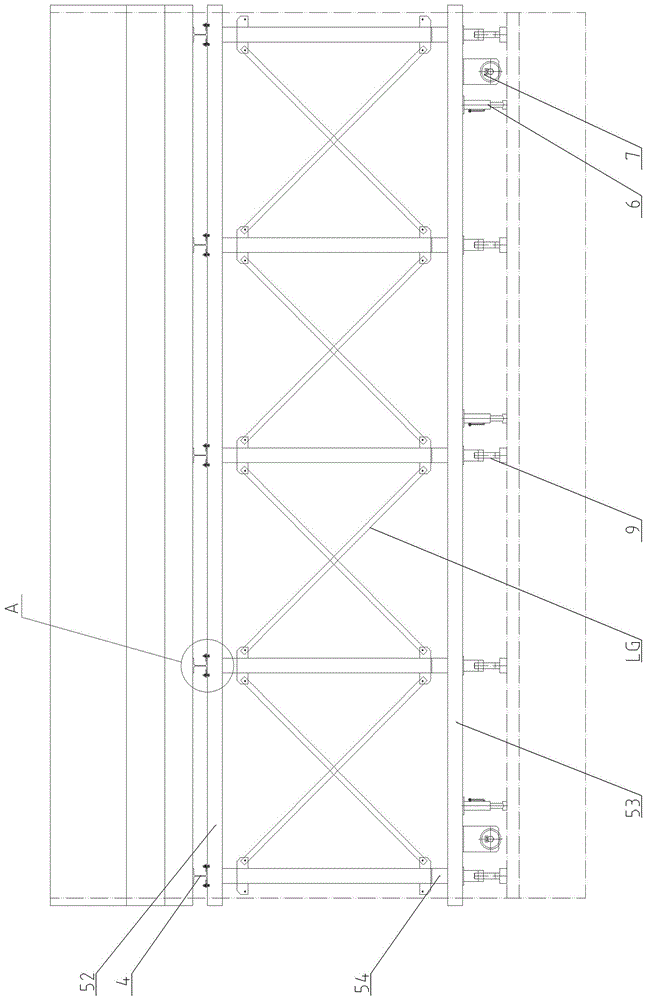

[0019] This embodiment discloses a hydraulic formwork trolley used for post-cast construction of a rail-top air duct, which mainly includes a formwork system and a support system.

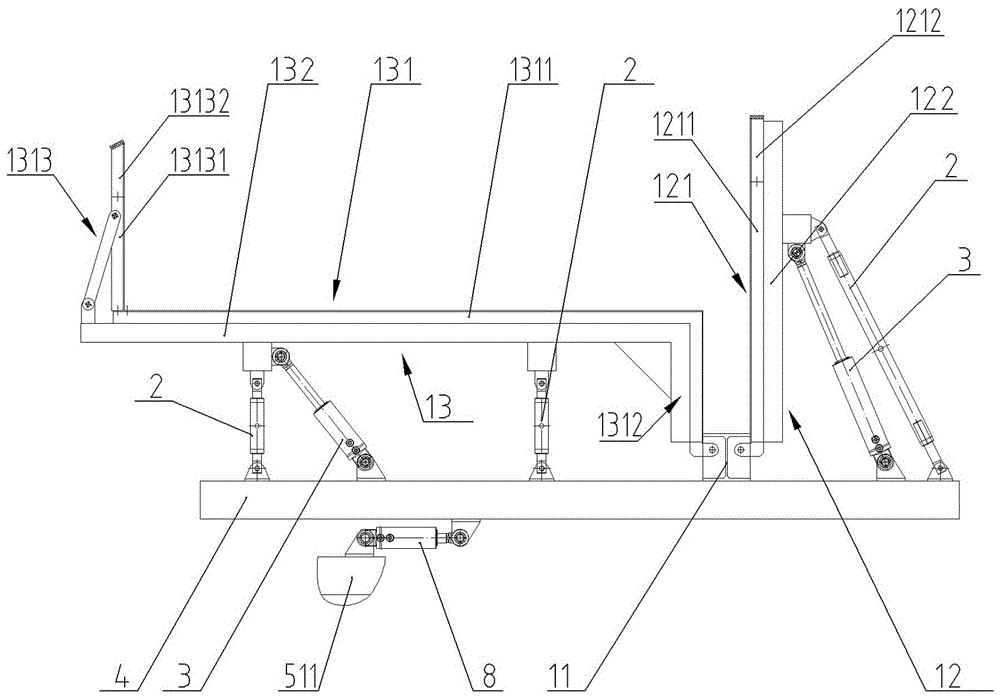

[0020] Such as figure 1 , figure 2 As shown, the template system includes a template 1 and its supporting members 2, a retracting and erecting mold mechanism 3, and a transverse beam 4.

[0021] Such as figure 1 , image 3 As shown, the template 1 includes a bottom mold 11, an outer movable mold 12 and an inner movable mold 13. The bottom mold 11 is made of H-shaped steel, and the outer movable mold 12 includes an outer template 121 and a number of outer connecting frames 122 longitudinally arranged along the outer side.

[0022] The outer template 121 includes a lower fixed-length mold 1211 and an upper movable mold 1212 connected to its upper end by bolts. The lower side of the lower fixed-length mold 1212 is hinged to a steel plate welded at a corresponding position of the bottom mold 11 through an ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com