Detachable high pressure abrasion-resistant pump

A high-pressure wear-resistant and wear-resistant lining technology, which is applied in the field of centrifugal pumps, can solve problems such as easy deflection of the volute outlet axis, difficult technology and process, and short service life, so as to reduce maintenance costs, small size, The effect of low casting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

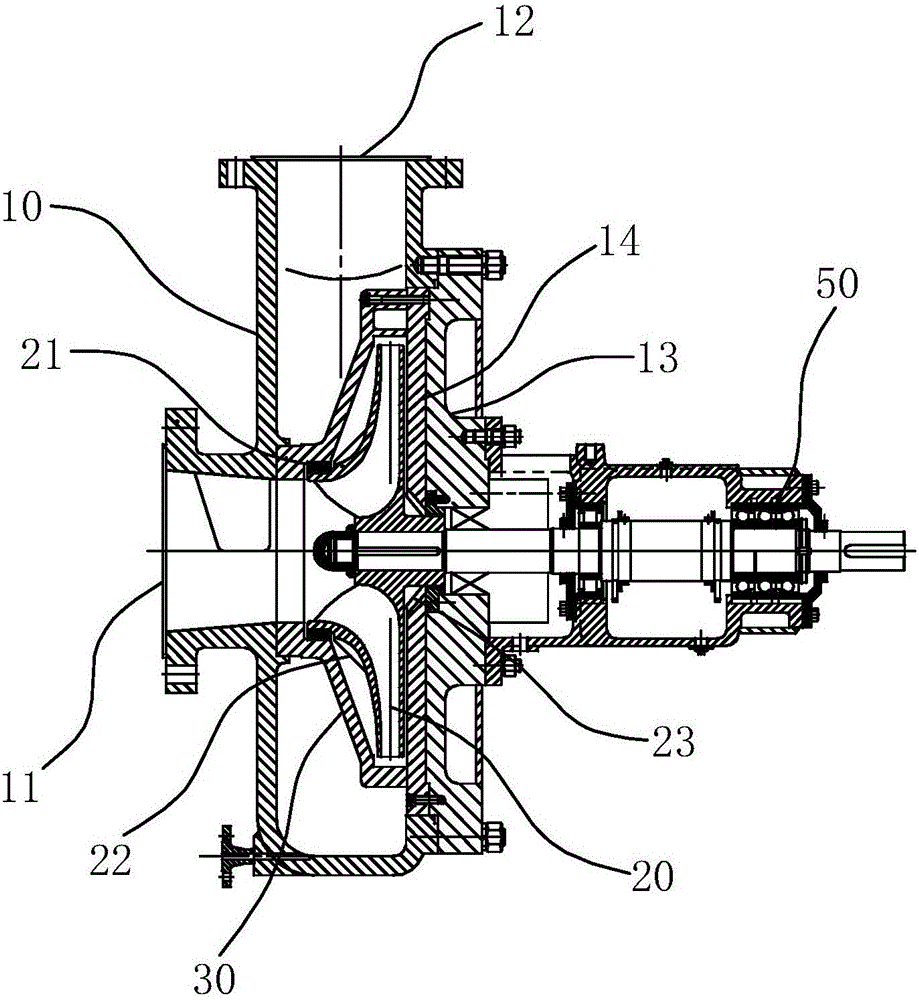

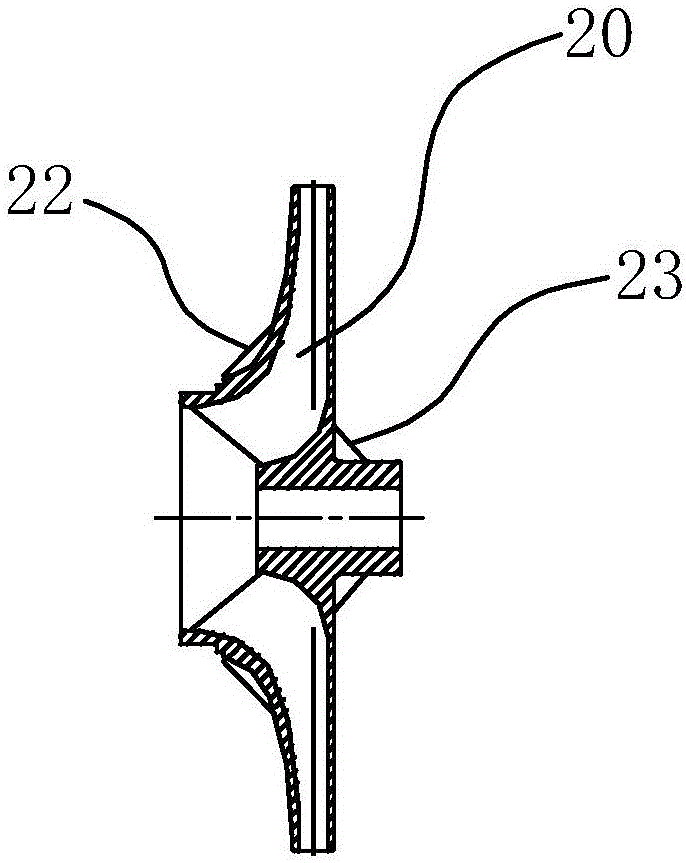

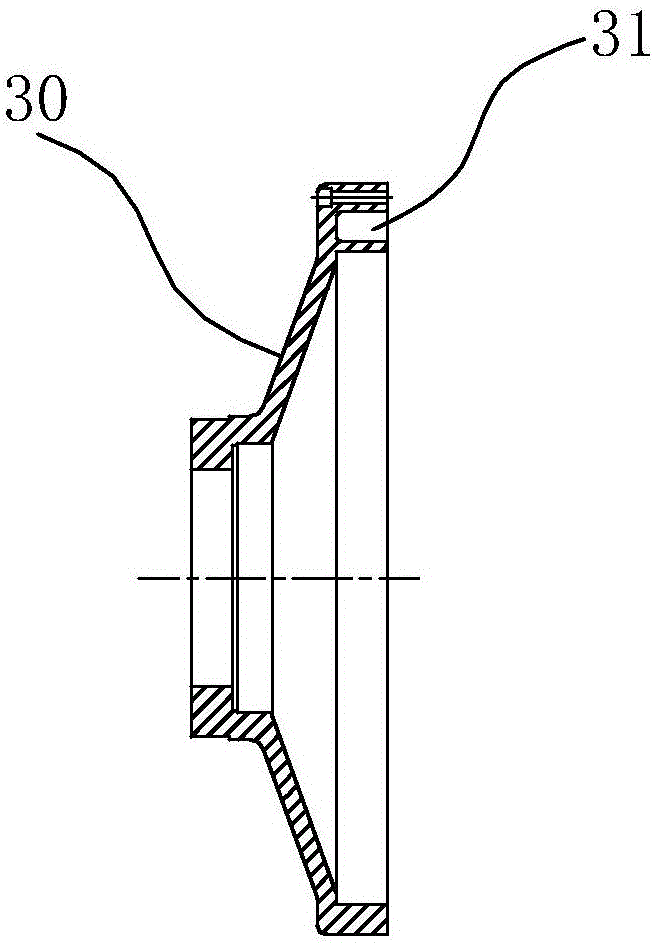

[0025] The present invention includes a pressure-resistant pump casing 10, which is provided with a feed port 11, a feed port 11, and an installation port. A pump cover 13 is installed at the installation port. The high-pressure wear-resistant pump also includes The centrifugal impeller 20 and the guide vane diffuser 30 installed in the pressure-resistant pump casing 10 through the installation port, the medium reaches the centrifugal impeller 20 through the feed port 11 and then passes through the guide vane diffuser 30 is decelerated and pressurized and transported to the discharge port 12. The centrifugal impeller 20 and guide vane diffuser 30 are all made of wear-resistant materials. The pump cover 13 is fixed to the pump casing 10 by bolts. The guide vane diffuser 30 used in the present invention is aimed at the characteristics of high pressure med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com