Gas exhaust device used for closed type hydraulic system

A technology of hydraulic system and exhaust device, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, mechanical equipment, etc., can solve problems such as affecting the life of hydraulic components, cavitation, reducing system reliability, etc. Longevity, effect of reducing cavitation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and examples.

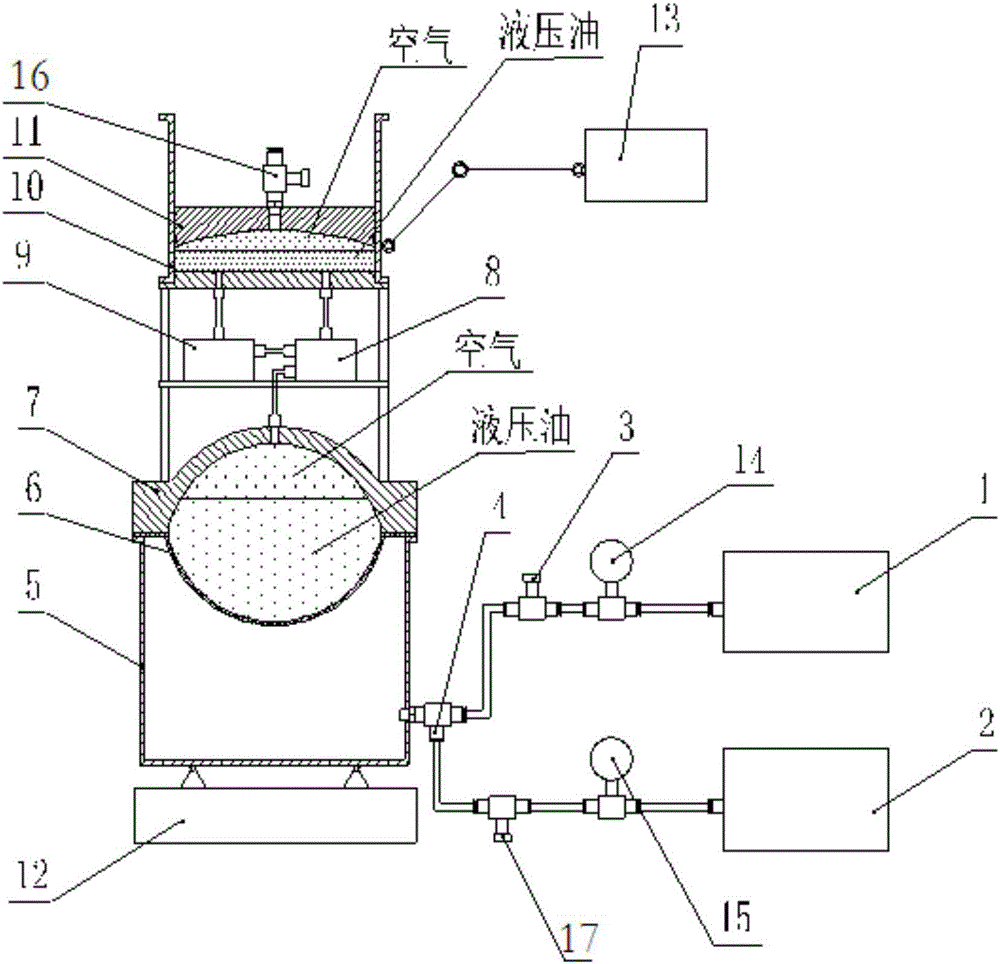

[0016] The invention provides an exhaust device for a closed hydraulic system, see the attached figure 1 , including: vacuum pump 1, air compressor 2, second stop valve 3, third stop valve 17, tee joint 4, sealing cover 5, swing mechanism 12, excitation mechanism 13, vacuum pressure gauge 14 and pressure gauge 15;

[0017] Its peripheral equipment is a closed hydraulic system, which includes: oil bag 6, pressure-resistant cover 7, valve group 8, hydraulic pump 9, oil tank 10, piston 11 and first stop valve 16; the bottom surface of the oil tank 10 is respectively provided with oil outlet and oil inlet; the oil bag 6 is docked with the pressure-resistant cover 7 to form a closed cavity, and hydraulic oil is housed in the closed cavity; the hydraulic pump 9 communicates with the closed cavity through the valve group 8; the oil tank 10 is equipped with Hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com