Laminated core type single-collar two-coil redundant axial direction magnetic bearing

A magnetic levitation bearing and laminated iron core technology, applied in the field of axial support, can solve the problems of stator and rotor heating, thermal deformation, large eddy current loss of solid stator core and thrust plate, etc., to reduce eddy current loss and reduce eddy current Loss, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

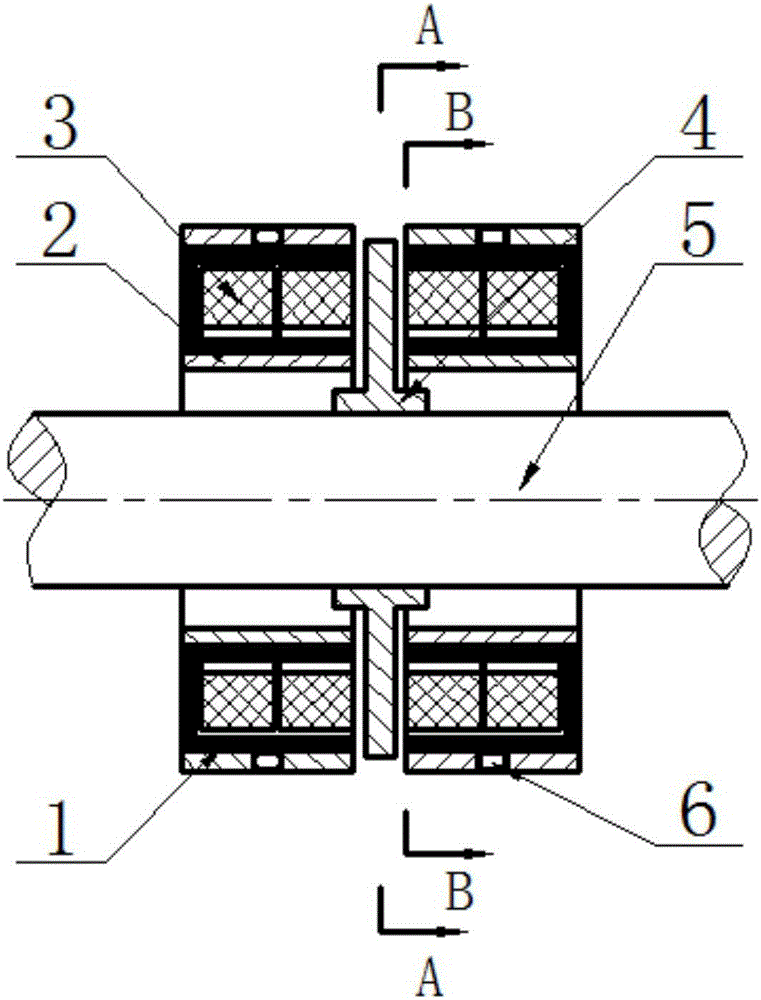

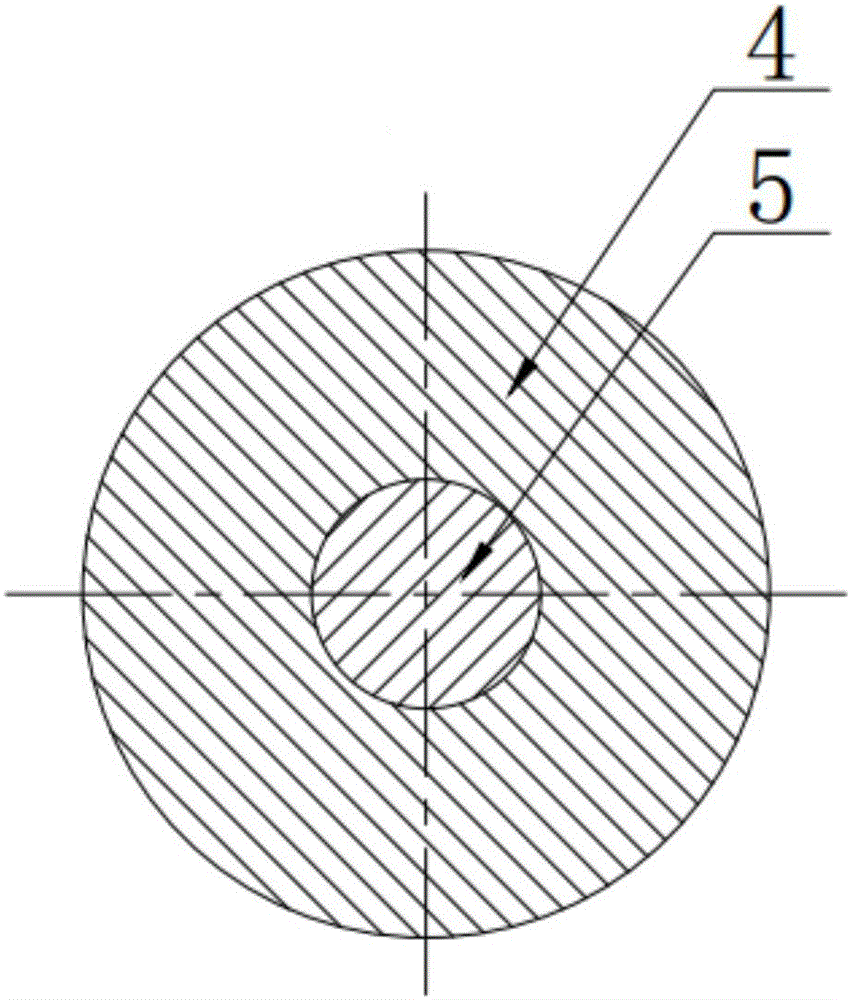

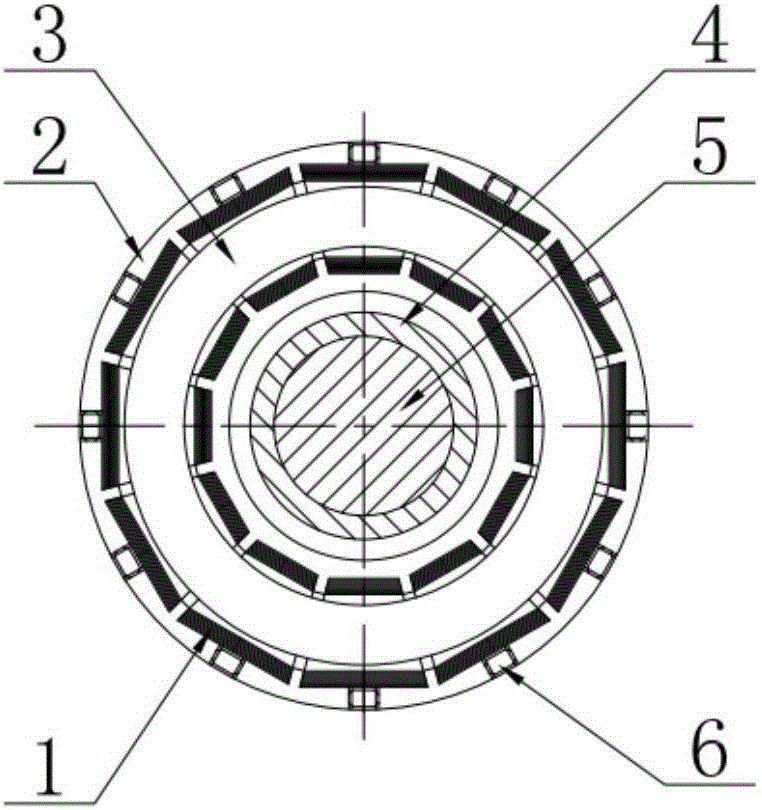

[0026] The laminated core type single-ring double-coil redundant axial magnetic suspension bearing provided by the present invention is mainly composed of U-shaped silicon steel lamination parts, lamination base, coil, thrust disc, rotor and hexagon socket flat end set screw , wherein: the thrust disc and the rotor are connected as a whole with an interference fit. The lamination bases of the two magnetic suspension bearings are respectively located on both sides of the thrust plate. Each lamination base has 12 trapezoidal grooves with the same structure evenly distributed along the circumferential direction, each trapezoidal groove is axially embedded with U-shaped silicon steel sheet lamination parts and fixed with set screws. Two groups of coils with the same number of turns are wound axially in parallel on a ring composed of 12 groups of U-shaped silicon steel laminations.

[0027] The present invention will be further described below in conjunction with the embodiments a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com