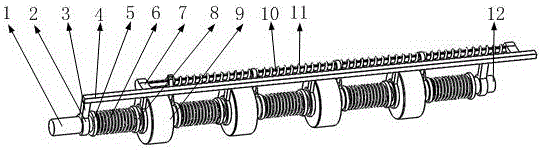

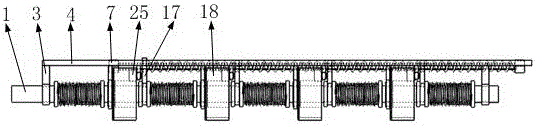

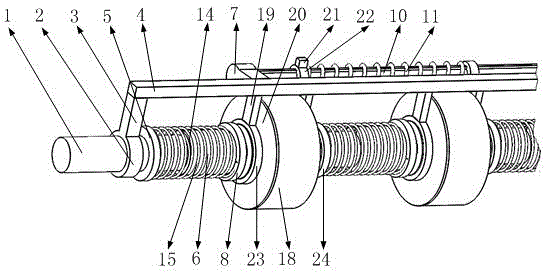

Multi-unit collinear driving transmission

A multi-unit, transmission technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of high cost, complex structure, large mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] The specific implementation method is as follows: at first, the four transmission shafts 37 all stretch out of the inner ring tooth support ring 42, and are respectively in contact with the circular plate in front. At this time, the input shaft 1 drives the output shaft 12 to rotate after being transmitted by the four transmission shafts 37. The speed of the output shaft 12 is the same as that of the input shaft 1; adjust the switching block 21, first the transmission shaft 37 in the first transmission unit 9 is completely pulled into the inner ring gear 18, and the input shaft 1 is in contact with the inner ring gear support ring 42 for friction , the inner ring gear 18 drives the sliding gear 29 to rotate through the intermediate gear 25, and then drives the transmission shaft 37 to rotate, realizing a first-level speed increase, and then continues to adjust the switching block 21, and the transmission shaft 37 in the second transmission unit 9 will be fully pulled Ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com