Pipe laying ship upper tensioning device and pipe line retractable winch tensile force testing method

A test method and tensioner technology, which is applied in the field of offshore oil engineering, can solve problems such as large space occupation and complex auxiliary facilities, and achieve the effects of simple operation, complex auxiliary facilities, and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

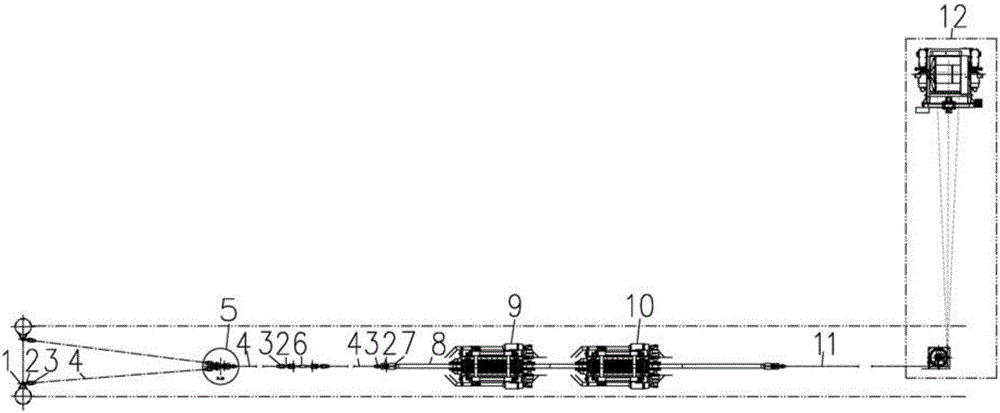

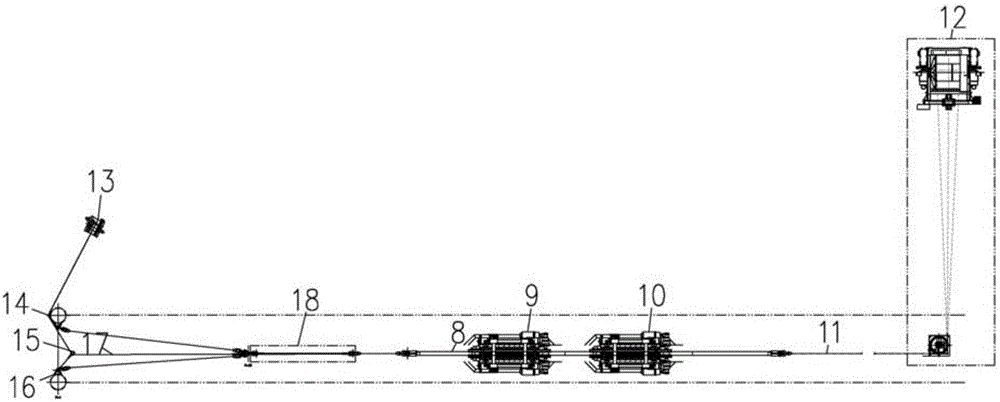

[0045] Such as figure 1 — Figure 4 As shown, the present invention is provided with: be located at the fixed drag point 1 of stern, during static test, one end of test sea pipe 8 is connected with the steel cable 11 of retractable winch 12, and the other end of test sea pipe 8 passes first wire rope 4 It is connected with the tension gauge 6, and the tension gauge 6 is connected with the fixed towing point 1 of the stern respectively through the first steel wire rope 4 and the towing triangular eye plate 5;

[0046] During the dynamic test, the tension meter 6 is replaced with the movable pulley block 18 (the second steel wire rope 17 one end of the movable pulley block 18 is fixed with the movable pulley block 18, and the other end of the movable pulley block 18 passes through the guide pulley and the guide column 14 fixed on the small drag point of the stern. Connect with test auxiliary winch 13.

[0047] Above-mentioned tension meter 6 is that measurement calibration has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com