Optical element damage detecting device and method based on polarization imaging

A technology for optical components and damage detection, which is used in measurement devices, optical testing of flaws/defects, and material analysis by optical means. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

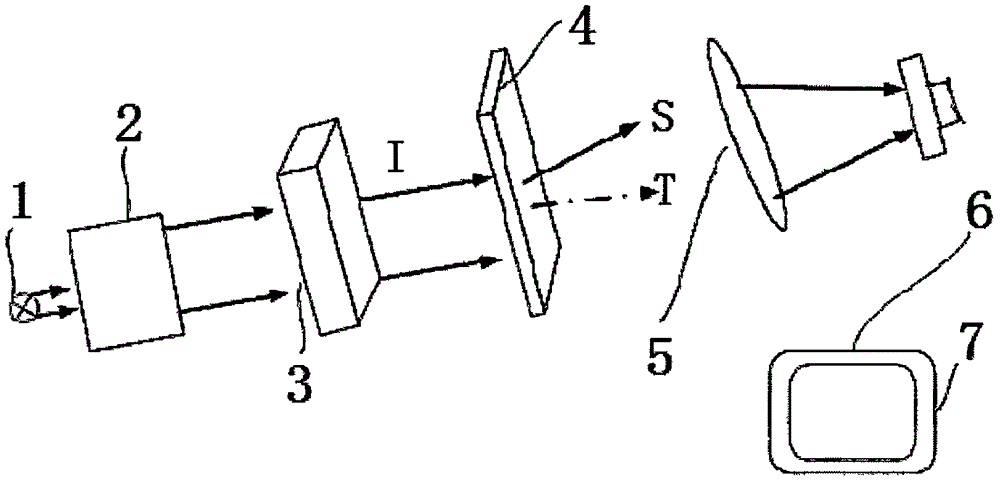

[0037] An optical element damage detection device based on polarization imaging proposed by the present invention includes a light source 1 and a beam expander system 2 arranged sequentially along the light source 1, a linear polarizer 3, an optical element under test 4, an imaging system 5, and a CCD Detector 6 , processing computer 7 , optical element under test 4 and CCD detector 6 are respectively located on the object plane and image plane of imaging system 5 , and the output end of CCD detector 6 is connected with the input end of processing computer 7 .

[0038] The beam expansion ratio of the beam expander system 2 is 5ט25×, and the maximum aperture is 300 mm.

[0039] The linear polarizer 3 adopts a quartz plate stack structure design, which is composed of 20 pieces of quartz flat glass, and the polarization degree of the outgoing light is better than 99%.

[0040] The imaging system 5 adopts a zoom design, the focal length range is 100mm-200mm, the field of view is ...

Embodiment 2

[0060] An optical element damage detection device based on polarization imaging proposed by the present invention includes a light source 1 and a beam expander system 2 arranged sequentially along the light source 1, a linear polarizer 3, an optical element under test 4, an imaging system 5, and a CCD Detector 6 , processing computer 7 , optical element under test 4 and CCD detector 6 are respectively located on the object plane and image plane of imaging system 5 , and the output end of CCD detector 6 is connected with the input end of processing computer 7 .

[0061] The beam expansion ratio of the beam expander system 2 is 10ט40×, and the maximum aperture is 500 mm.

[0062] The linear polarizer 3 adopts a quartz plate stack structure design, which is composed of 25 pieces of quartz flat glass, and the polarization degree of the outgoing light is better than 99%.

[0063] The imaging system 5 adopts a zoom design, the focal length ranges from 200mm to 400mm, the field of v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com