Inductor for integrated circuit

A circuit and device technology, applied in the structural field of making inductors, can solve problems such as complex inductance and non-constant inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The microstrip transmission line of the present invention is adopted in the following several structures:

[0040] - Straight line microstrip

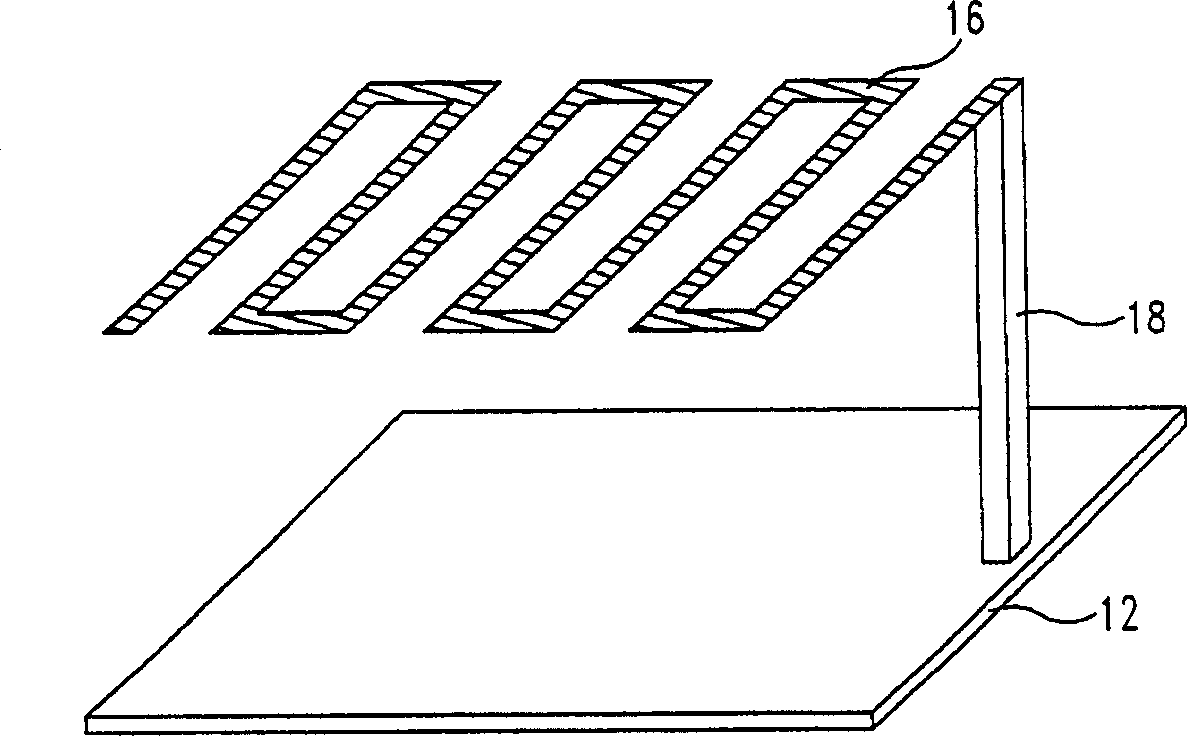

[0041] -Curve structure

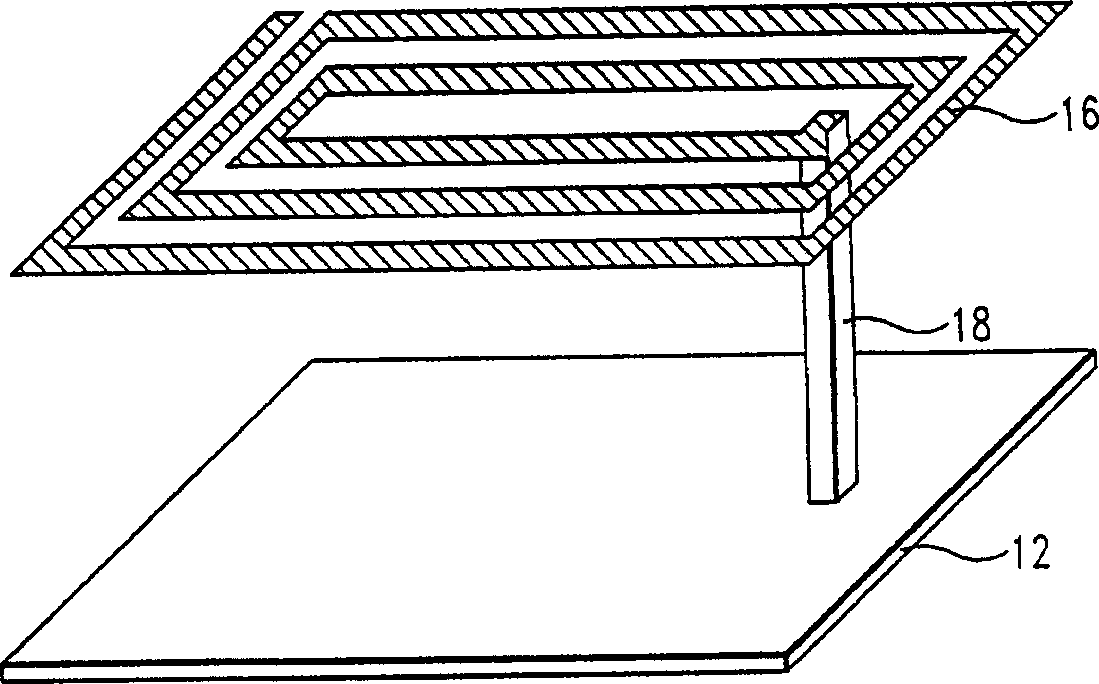

[0042] - helical structure

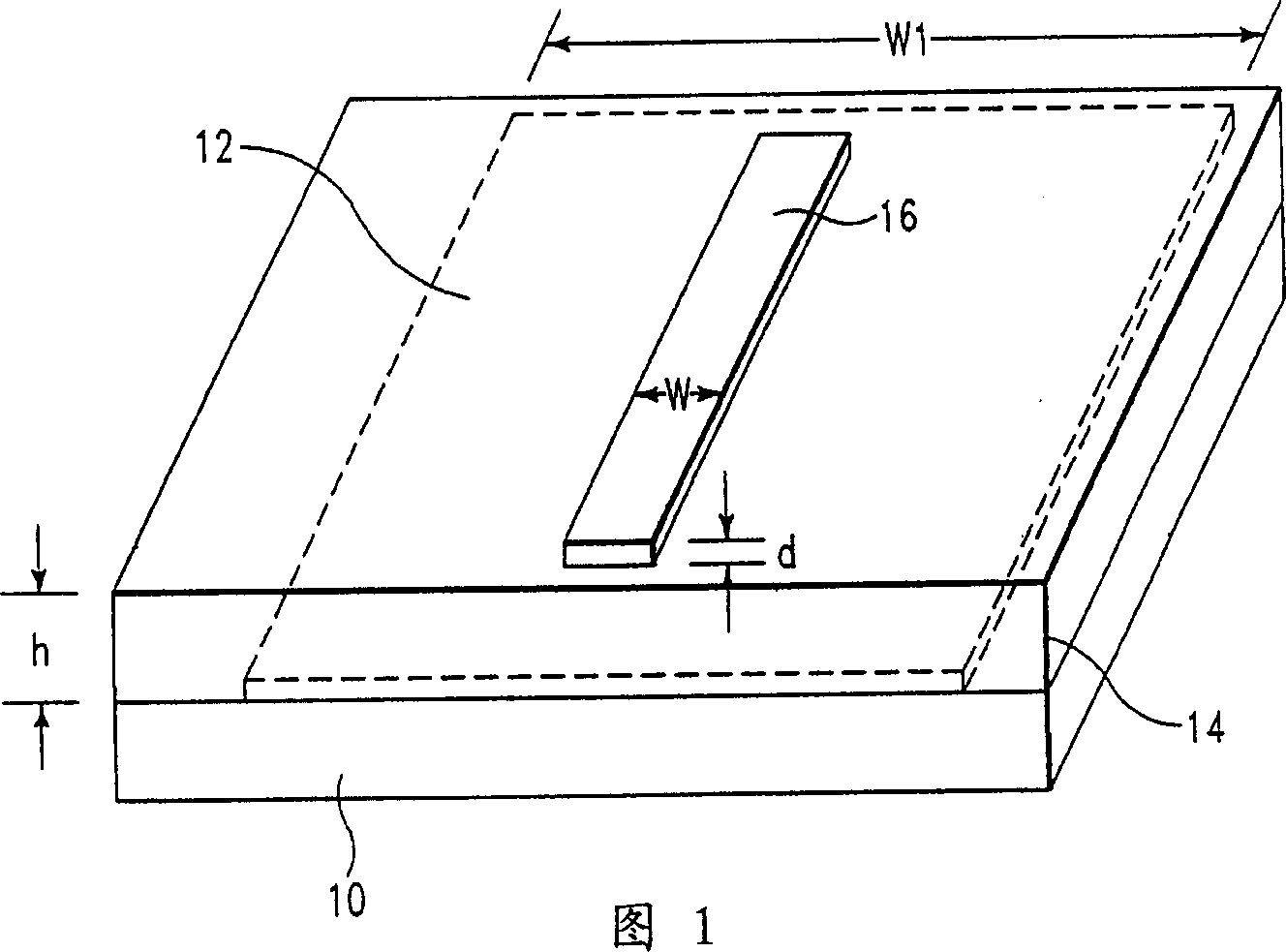

[0043]The linear microstrip structure is shown in FIG. 1, in which the center conductor 16 as a signal transmission conductor is made of aluminum or copper. The two types of metallization techniques have different advantages for system optimization. Copper has a lower resistivity than aluminum, but aluminum wire can be made thicker without special treatment. It is desirable to increase the thickness of the center conductor to achieve lower overall resistance. The width of the center conductor is W, the thickness is d, and the distance between the center conductor and the metal plane 10 below it is h, which is an interlayer insulating material in the integrated chip substrate 10 . The integrated chip substrate preferably contains a multifunctional integrated circuit to w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com