Optical axis debugging system and method of laser range finder

A laser ranging and debugging system technology, applied in the laser field, can solve problems such as unfavorable debugging, limitations of subjective factors, low work efficiency, etc., and achieve the effect of improving optical axis debugging accuracy, high optical axis debugging accuracy, and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

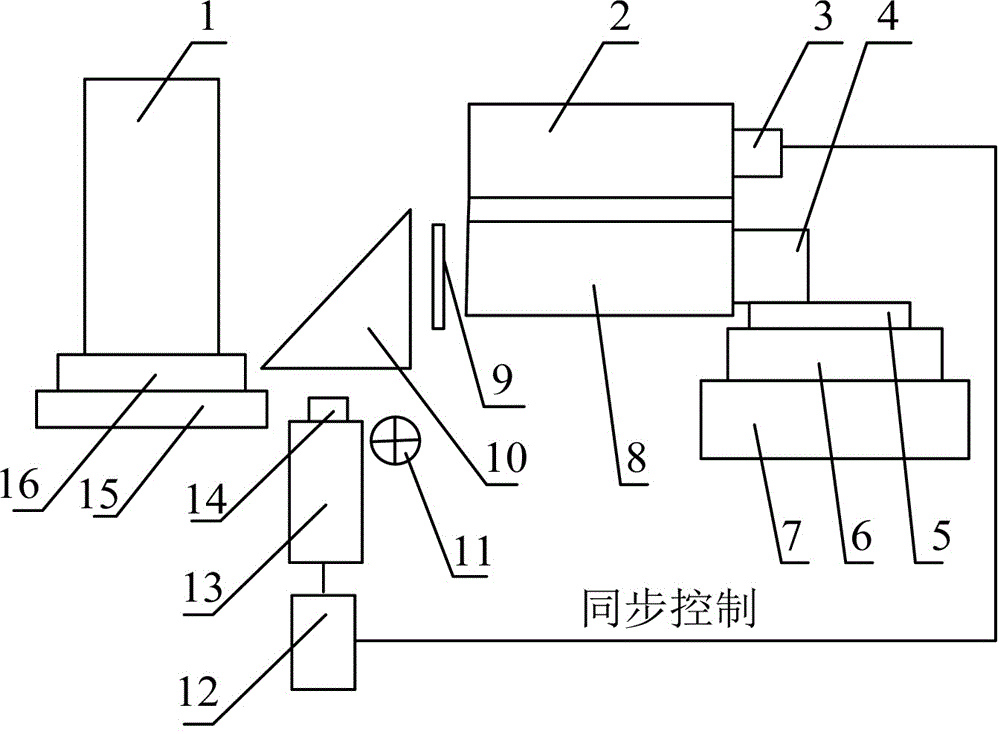

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0039] refer to figure 1 As shown, the present invention discloses a laser distance measuring machine optical axis debugging system, comprising a laser 3, an illumination light source 11 and a CCD camera 13 with a CCD lens 14, the front of the laser 3 is connected with an emission optical system 2, the A computer 12 is connected between the CCD camera 13 and the laser 3, a receiving optical system 8 is arranged in parallel below the emitting optical system 2, and a detector assembly 4 is connected behind the receiving optical system 8, and the receiving optical system 8 is connected with a detector assembly 4. The front of the system 8 is provided with an attenuation sheet 9, a right-angle prism 10 and a corner cube 1 successively, and the right-angle prism 10 can deflect light beams by 90 degrees, wherein the corner cube 1 is positioned at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com