All-fiber precision variable optical attenuator

A dimming attenuation and all-fiber technology, applied in the field of optical fiber communication, can solve the problems that hinder the improvement of the dynamic range and precision of the fiber attenuator, limit the dynamic range and precision of the fiber attenuator, and the size cannot be too large, etc., to achieve the use mode Flexibility, lower implementation costs, and increased dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

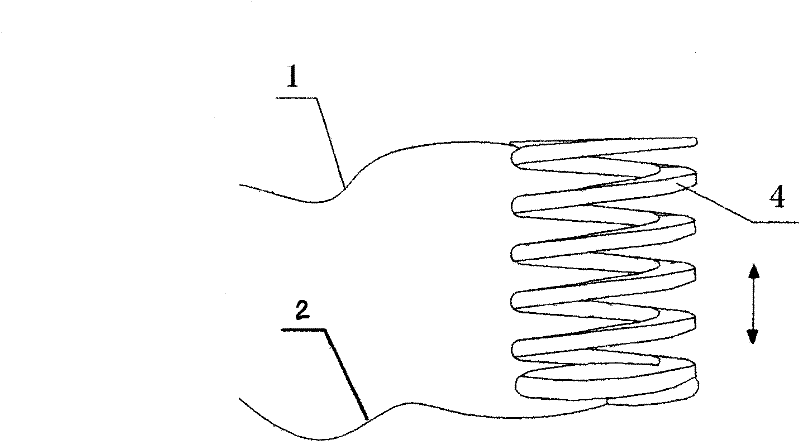

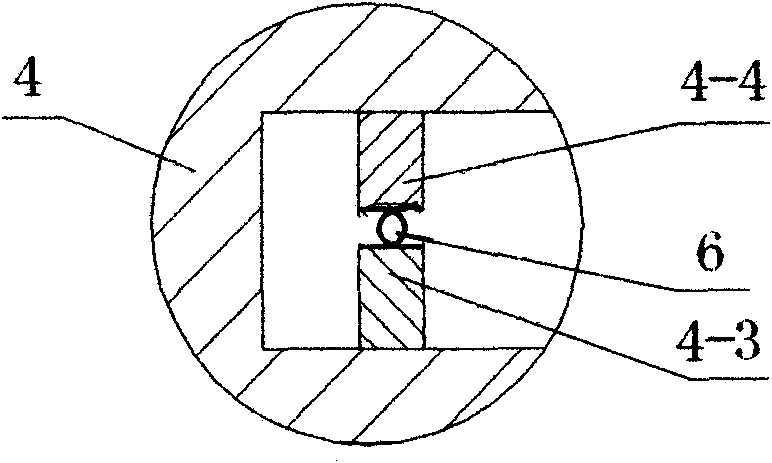

[0049] Such as figure 1 , figure 2 As shown, the present invention includes a curved casing 4 and a plurality of A-side deformation teeth 4-4 and a plurality of B-side deformation teeth continuously arranged on opposite sides of the interior of the curved casing 4 along the longitudinal direction of the curved casing 4. 4-3, when the relative positions of the two ends of the curved housing 4 change, the position between the A-side deformation teeth 4-4 and the B-side deformation teeth 4-3 inside the curved housing 4 also changes, and the A-side deformation The teeth 4-4 and the B-side deformed teeth 4-3 are arranged in a staggered manner, and a light-guiding optical fiber 6 is clamped between the two deformed teeth, and the A-side deformed teeth 4-4 and the B-side deformed teeth 4-3 are correspondingly arranged on the guide On both sides of the optical fiber 6, the two ends of the light guiding fiber 6 are respectively connected to the optical fiber 1 for inputting optical s...

Embodiment 2

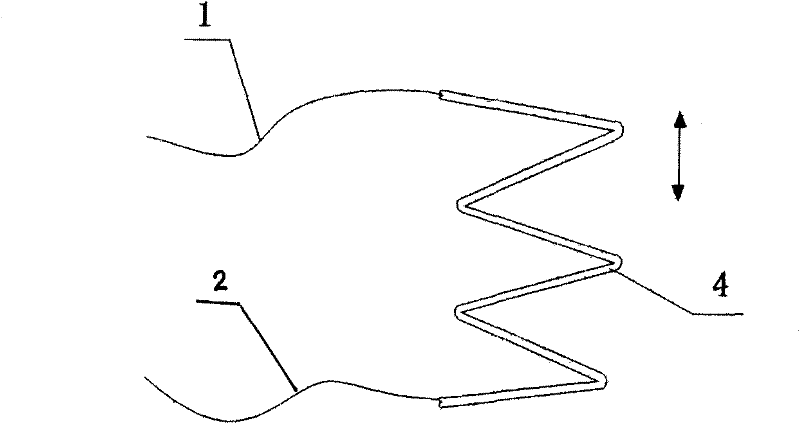

[0052] Such as image 3 , Figure 4 As shown, in this embodiment, the difference from Embodiment 1 is that the curved housing 4 is in a Z-shape as a whole, and the cross-sectional shape of the curved housing 4 is circular, which is also The cross-section of the curved housing 4 can be processed into various other shapes such as an elliptical ring. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

[0054] Such as Figure 5 , Figure 11 As shown, in this embodiment, the difference from Embodiment 1 is that there is a slidingly fitted restricting body 16 on the outside of the curved housing 4, which prevents the curved housing 4 from being twisted and deformed arbitrarily, and the curvilinear housing 4 One end is fixed on a base plate 15, and the other end is connected and matched with a slider 14. The slider 14 slides and fits with a limiting body 16 fixed on the base plate 15. Here, the limiting body 16 serves as a slide rail of the slider 14 at the same time. The housing 4 and the base plate 15 are placed in a casing cavity 3, and there is a screw 12 threadedly engaged with the slider 14. The other end of the screw 12 extends to the outside of the casing cavity 3, and at this A knob 11 for controlling the rotation of the screw rod 12 is placed at the end, and a signal optical fiber 8 and a signal optical fiber 8 are clamped side by side with the light guide optical fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com