A low-cost miniature projection system based on LEDs and lenses

A micro-projection and lens technology, applied in the field of projectors, can solve the problems of high difficulty in processing and installation, increased power consumption of the system, color deviation, etc. The effect of the effect of astigmatism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

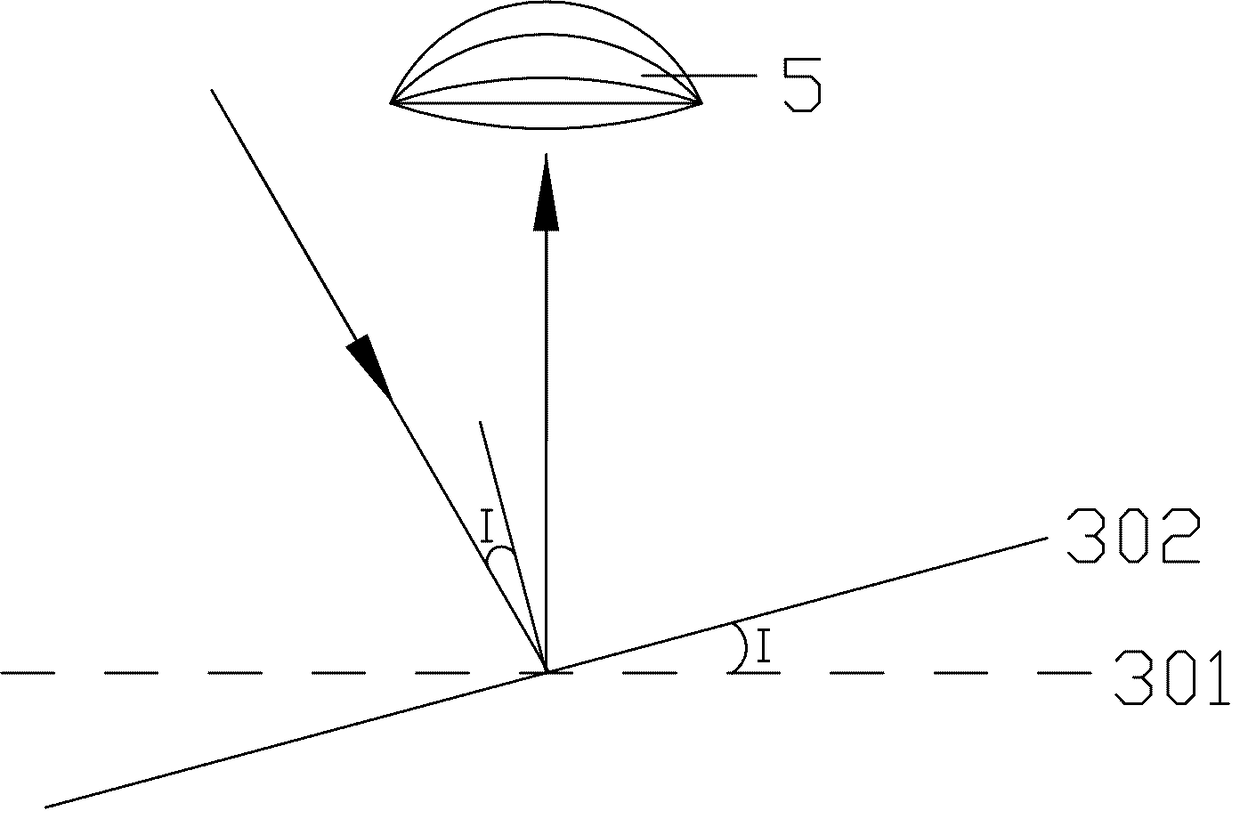

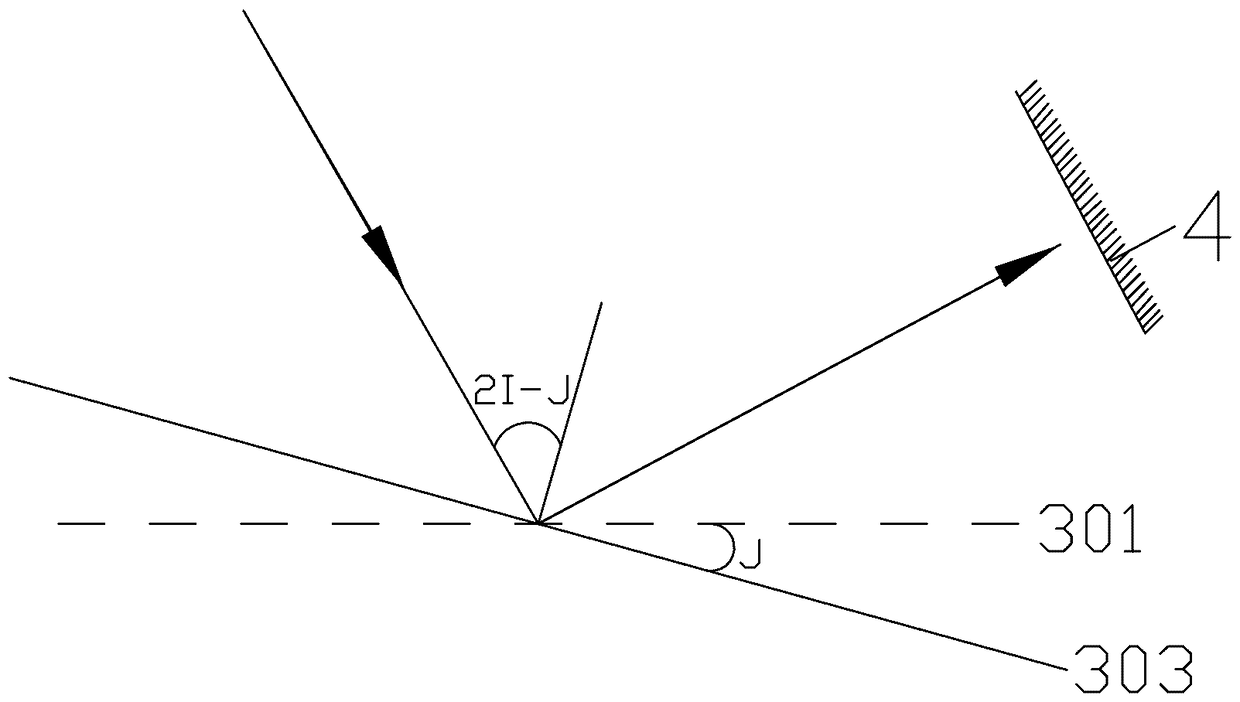

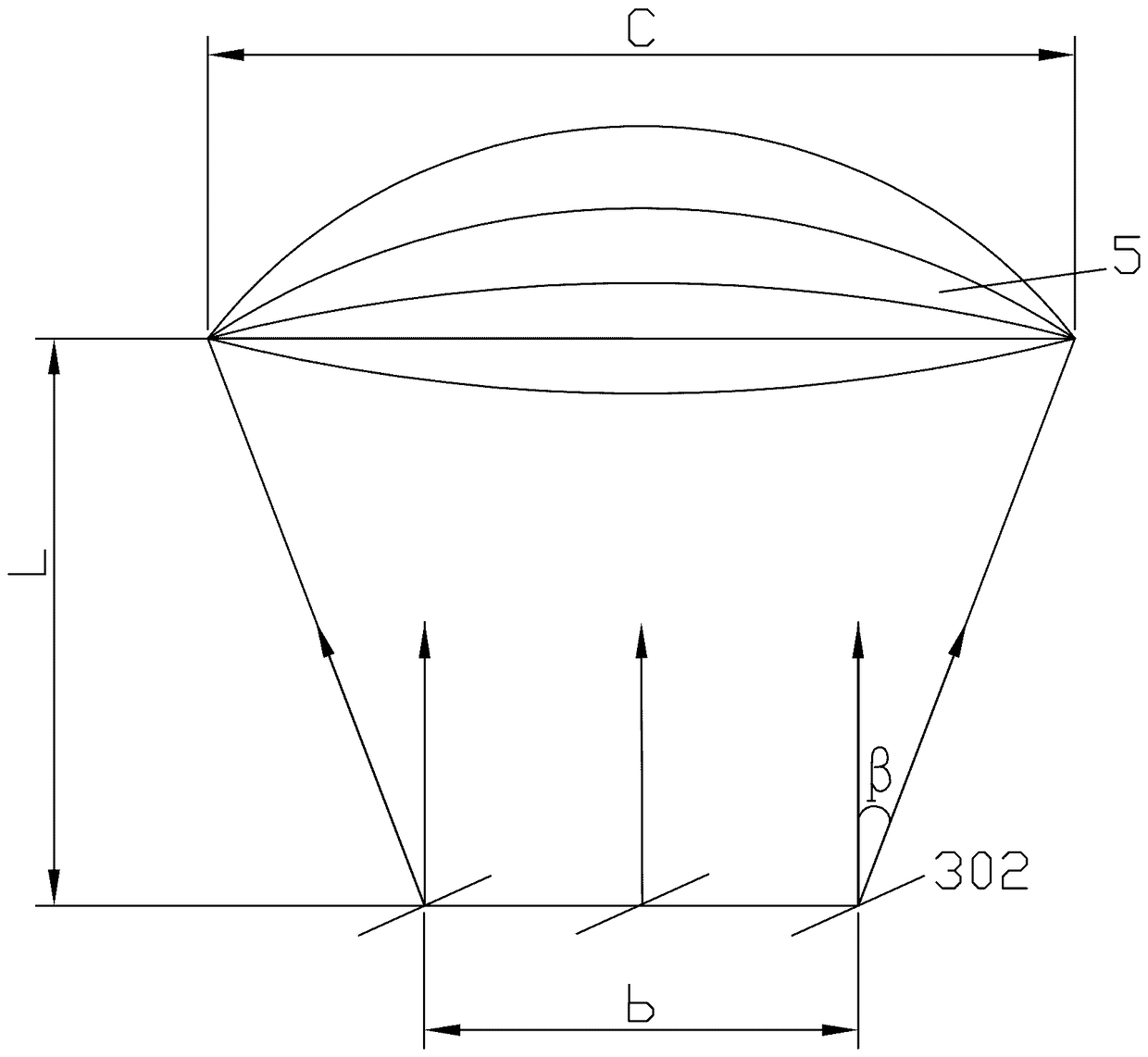

[0054] Embodiment one sees Figure 4 , the optical path of the projection system using LED and convex lens, including LED, convex lens, digital micromirror element, projection lens, absorption device, using convex lens as the shaping lens, the projection system uses a single high-power tri-color LED as the light source, packaged in one LED There are three light-emitting diodes, red, green and blue.

[0055] The single high-power tri-color LED uses the CLMUC-FKA LED lamp bead of Cree Company. The package size of the lamp bead is small, only 1.5mm×1.5mm×1.0mm, and the LED has four pins. The pins that emit red, green, and blue lights are respectively connected to the negative pole, and the remaining common pin is connected to the positive voltage. By controlling the voltage or current of the three pins of red, green, and blue to control the three colors Change; by controlling the strength of the current or the duty cycle, to control the luminous intensity of the three colors.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com