Operational method of PLC real-time operating data recording storing system

A data recording and storage system technology, applied in general control systems, control/regulation systems, sequence/logic controller program control, etc., can solve the problem that the operating data of a single PLC system cannot be stored for a long time, and achieve traceability The effect of reliability, low cost and simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

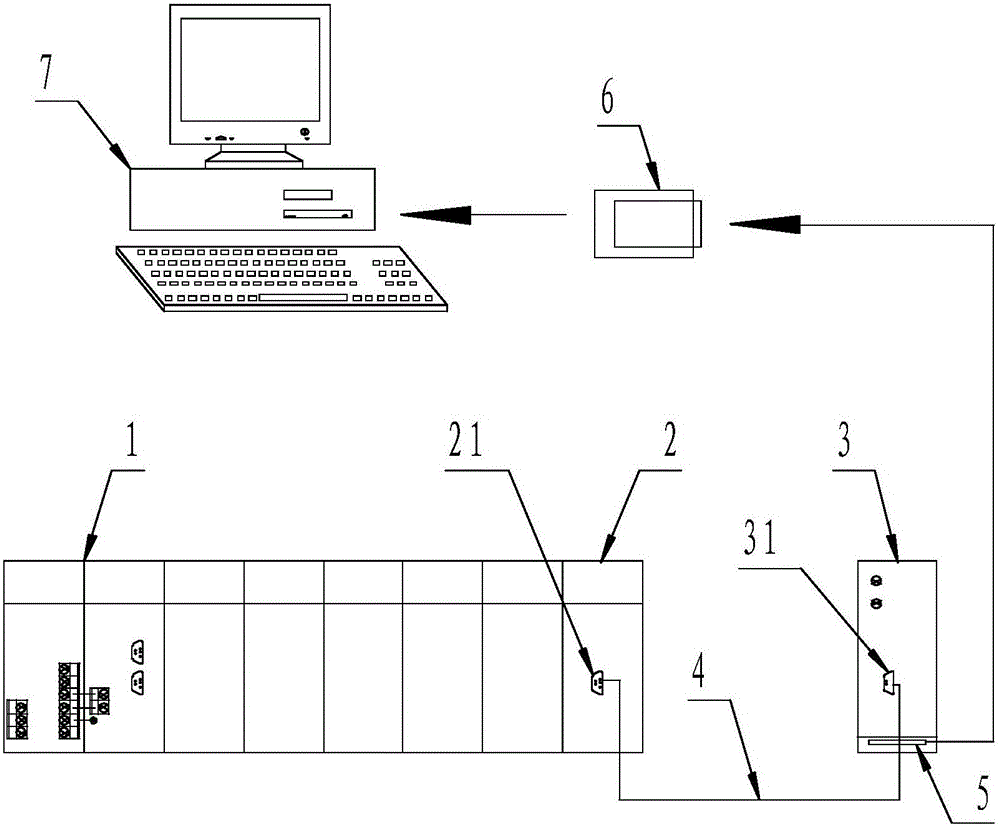

[0040] One end of the PLC control system 1 is equipped with a serial communication module 2, the serial communication module 2 is equipped with an RS-232 serial communication protocol port 21, the data memory 3 is configured with a serial communication receiving port 31, and the RS-232 serial communication protocol port 21 is connected with the serial communication receiving port Communication line 4 is arranged between 31, and described PLC control system 1 adopts Siemens S7-300 series, CPU-315-2DP, and described serial communication module 2 adopts CP340, and described data memory 3 adopts LDS1 model product, and described communication line 4 Adopt standard DB9RS-232 communication line;

[0041]Perform hardware configuration and configuration first, then PLC programming, and then transfer and save data. When you need to view data, take out the TF memory card 5 in the data storage 3, insert it into the card reader 6, and then insert it into the computer 7 to view the TF memor...

Embodiment 2

[0043] The specific operation steps of the hardware configuration configuration are as follows:

[0044] In the first step, after the hardware connection is completed, it is necessary to use Siemens PLC programming software Step7V5.5 to configure the hardware of the PLC control system 1, serial communication module 2 and data storage 3, the purpose of which is to ensure that the serial communication module 2 and data storage The communication parameter settings of 3 are consistent, open the project in the manager button SIMATIC in the Siemens PLC programming software Step7V5.5, call the HWCONFIG configuration table, double-click CP340RS232C, and open the dialog box of the property button CP 340-RS232Cproperties;

[0045] The second step is to write down the module address in the address button Addresses. When calling FBP_PRINT in the user program, the module address needs to be used as a parameter;

[0046] The third step is to click the command button in the parameter button ...

Embodiment 3

[0054] The specific operation steps of the PLC programming are as follows:

[0055] In the first step, after the hardware configuration is completed, the PLC needs to be programmed, the purpose is to send out the RS-232 serial communication protocol port 21 of the required data communication serial communication module 2, first in the manager button SIMATIC Use the file button File>Open button Open...>Library button Libraries in the Siemens\STEP7\S7libs\CP PtP directory to open the CP 340 and its block container of the block button Blocks folder;

[0056] The second step is to open a window consisting of the library title and the FB and FC belonging to the CP 340, and copy FB 4 to the block button Block folder of the project;

[0057] The third step, in the SIMATIC manager button, use the file button File>Open button Open...>Library button Libraries in the Siemens\STEP7\S7libs\StdLib30 directory to open the block button Blocks folder IEC function block and its block container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com