Slow wave module tube extrusion and detection controlling system and method

A control system and tube-and-tube technology, which is applied in general control systems, control/regulation systems, digital control, etc., can solve the damage of slow-wave components, the extrusion process and deformation of the tube-shell cannot be accurately controlled, and cannot meet the requirements of slow-wave components. Design and assembly requirements and other issues to achieve the effect of preventing equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

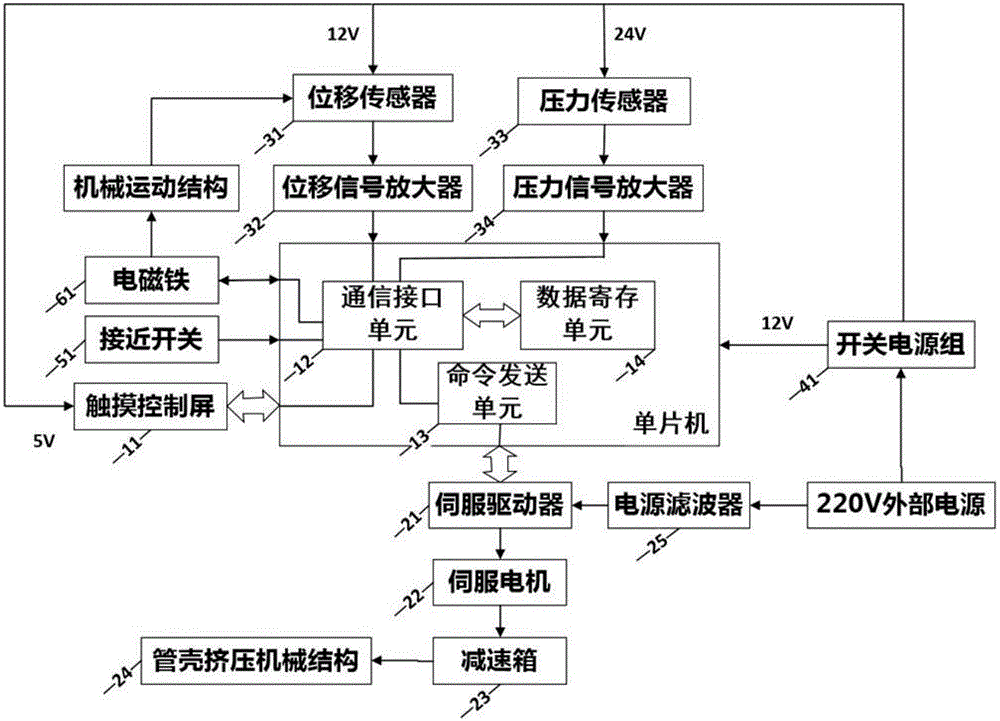

[0023] A control system for extruding and detecting the shell of a slow-wave component according to the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] figure 1 A control system for extruding and detecting the shell of a slow-wave component is shown, including a micro-control unit, an extruding drive unit for the shell, a deformation information detection unit, a switching power supply group 41, a proximity switch 51, and an electromagnet 61;

[0025] The micro control unit includes: a touch control screen 11, a communication interface unit 12, a command sending unit 13, and a data registering unit 14;

[0026] The casing extrusion drive unit includes: a servo driver 21, a servo motor 22, a reduction box 23, a casing extrusion mechanical structure 24, and a power filter 25;

[0027] The deformation information detection unit includes: a displacement sensor 31, a displacement signal amplifier 32, a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com