Method for manufacturing a dimming apparatus

A technology of a display device and a manufacturing method, which is applied in the directions of display devices, illuminated signs, light guides of lighting systems, etc., can solve the problems of cumbersome manufacturing processes and limitations in thinning, and achieves reduction of bonding processes, realization of thinning, The effect of easy thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

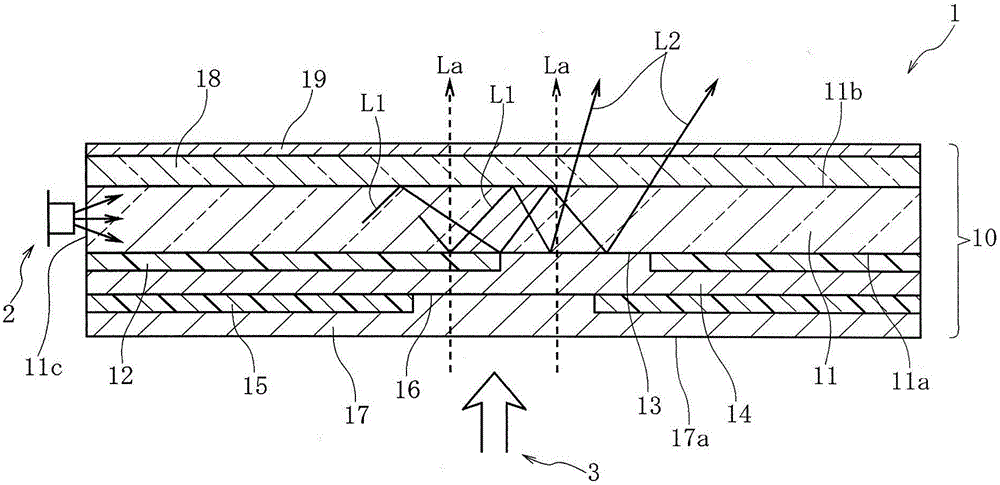

[0054] figure 1 The illumination display device 1 according to the first embodiment of the present invention is shown.

[0055] The illuminating display device 1 has a laminated body 10 , the first light transmitting unit 2 is provided facing the side of the laminated body 10 , and the second light transmitting unit 3 is provided facing the lower side of the laminated body 10 in the drawing.

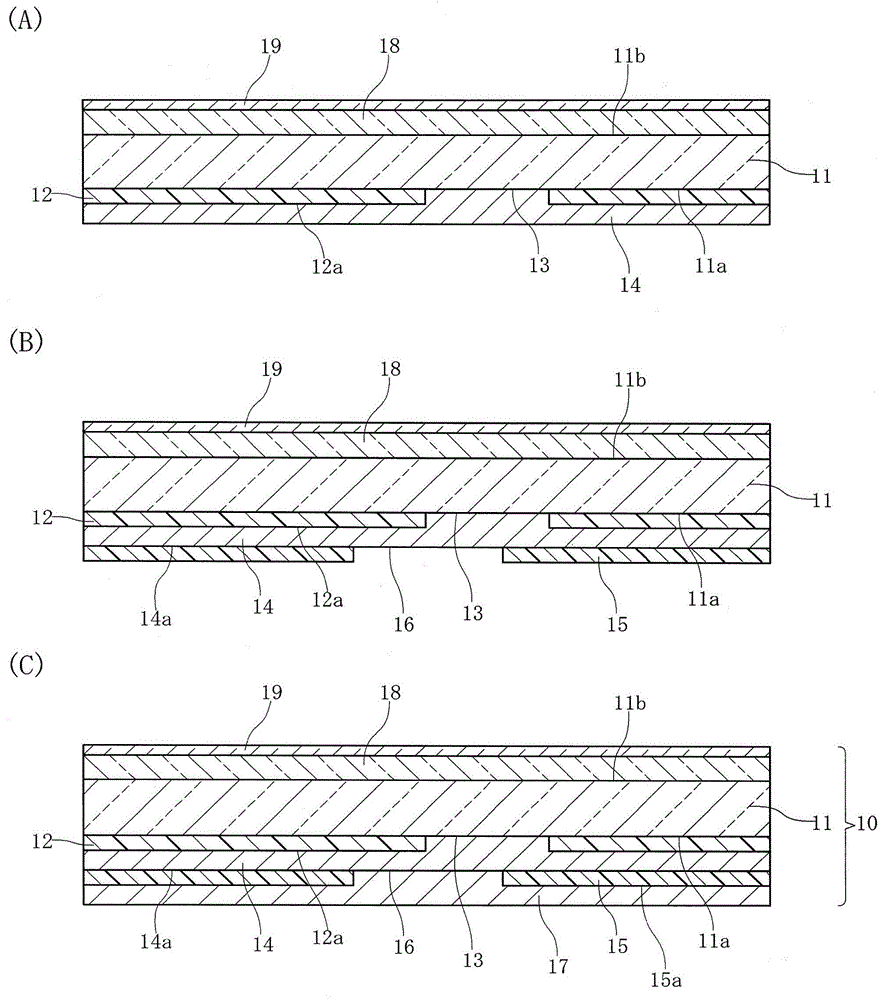

[0056] exist figure 2 (A) (B) (C), the manufacturing process of the laminated body 10 is shown sequentially as a manufacturing method of the illumination display device 1.

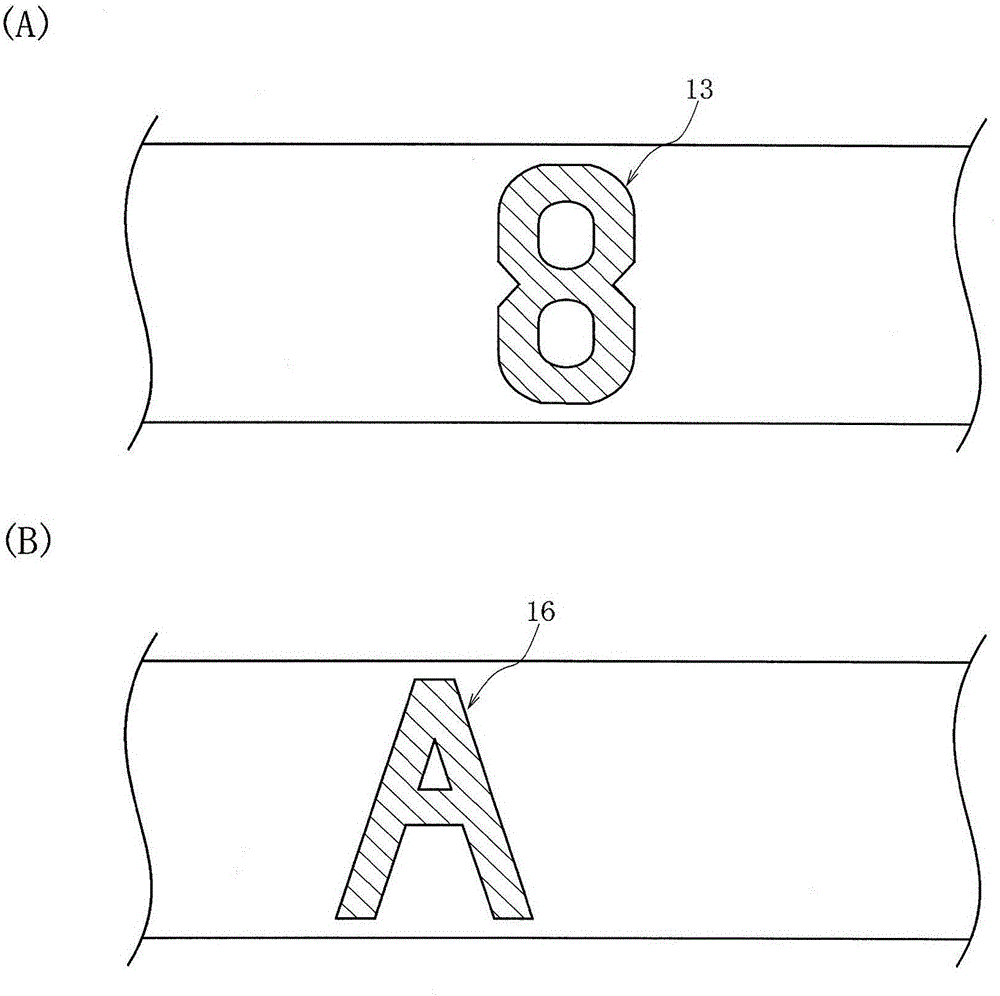

[0057] The laminated body 10 has a light guide layer 11 . The light guide layer 11 is formed of a translucent and flexible synthetic resin sheet or synthetic resin plate, such as a polyurethane sheet, polycarbonate sheet, or PET (polyethyleneterephthalic acid) sheet. The plane of the light guide layer 11 facing the lower side in the drawing is the light incident side surface 11 a , and the plane facing the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com