Manufacture method of waterproof plastic wiring harness

A production method and technology for plastic wires, which are applied in the manufacture of wire harnesses, cable/conductor manufacture, electrical components, etc., can solve the problems of insufficient filler penetration, low production cost, and high production efficiency, and achieve low material costs and low production costs. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a method for making a waterproof plastic wire harness, comprising the following steps:

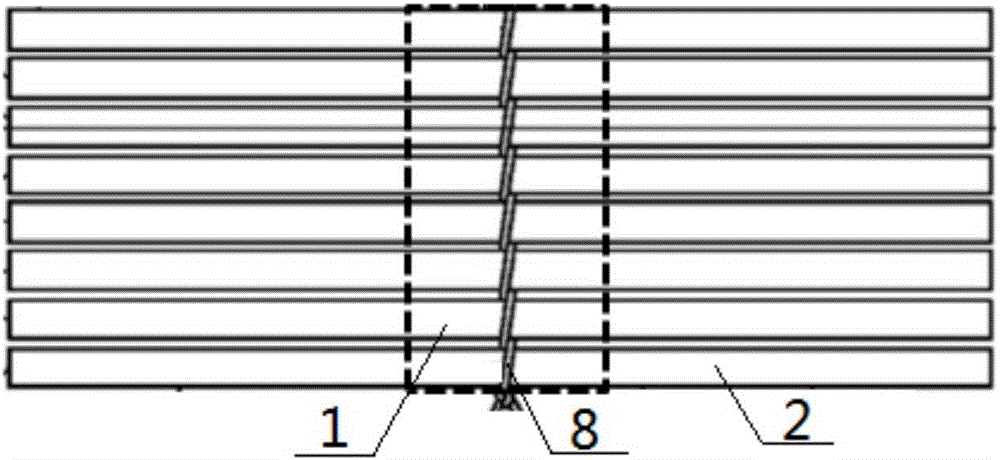

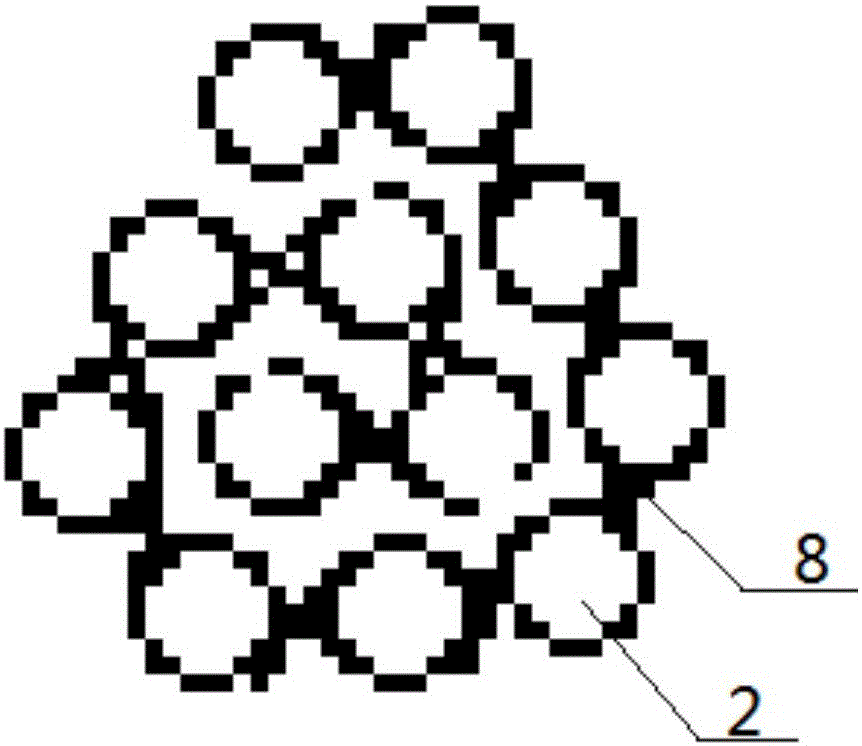

[0033] Step 1. Arranging a bundle of wires with a waterproof part 1. The number of wires is greater than 2. The wires are divided into an inner wire bundle 2 and an outer wire bundle 7 according to the ratio of the number of wires within the range of 1-2:3. Such as figure 1 The two ends of the waterproof part 1 of the inner wire bundle 2 are braided with cotton thread 8 so that the inner wire bundle 2 is connected to each other in the shape of a rolling curtain, wherein the diameter of the cotton thread 8 is the diameter of each of the wires Before weaving the cotton thread 8, soak the cotton thread 8 in liquid paraffin and drain until the liquid paraffin does not drop within 2-5 minutes after the cotton thread 8 is picked up. The intersection between two adjacent wires of the wire harness 2 is X-shaped, the length of the waterproof part 1 of the outer wire h...

Embodiment 2

[0039] The invention provides a method for making a waterproof plastic wire harness, comprising the following steps:

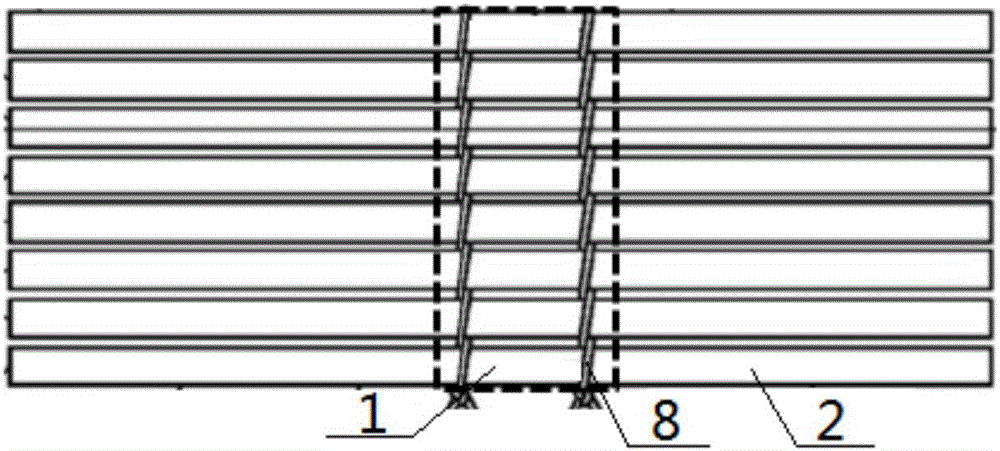

[0040] Step 1. Arranging a bundle of wires with a waterproof part 1. The number of wires is greater than 2. The wires are divided into an inner wire bundle 2 and an outer wire bundle 7 according to the ratio of the number of wires within the range of 1-2:3. Such as figure 2The middle of the waterproof part 1 of the inner wire harness 2 is braided with cotton thread 8 so that the inner wire bundles 2 are connected to each other in the shape of a rolling curtain, wherein the diameter of the cotton thread 8 is 1 / 3 of the diameter of each wire. One tenth, before weaving the cotton thread 8, soak the cotton thread 8 in liquid paraffin and drain until the liquid paraffin does not drop within 2-5 minutes after picking up the cotton thread 8, and the cotton thread 8 is in the inner bundle 2 The intersection between two adjacent wires is X-shaped, the length of the w...

Embodiment 3

[0045] The invention provides a method for making a waterproof plastic wire harness, comprising the following steps:

[0046] Step 1. Arranging a bundle of wires with a waterproof part 1. The number of wires is greater than 2. The wires are divided into an inner wire bundle 2 and an outer wire bundle 7 according to the ratio of the number of wires within the range of 1-2:3. Such as figure 1 The two ends of the waterproof part 1 of the inner wire bundle 2 are braided with cotton thread 8 so that the inner wire bundle 2 is connected to each other in the shape of a rolling curtain, wherein the diameter of the cotton thread 8 is the diameter of each of the wires Before weaving the cotton thread 8, soak the cotton thread 8 in liquid paraffin and drain until the liquid paraffin does not drop within 2-5 minutes after the cotton thread 8 is picked up. The intersection between two adjacent wires of the wire harness 2 is X-shaped, the length of the waterproof part 1 of the outer wire h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com